Choke

The choke consists of a bi-metal, spiral strip, electric

heating element, and choke pulloff diaphragm. The bi-

metal coil is connected to the choke shaft and holds the

choke plate nearly closed when the engine is cold.

When the engine starts, vacuum from the intake mani-

fold causes the pulloff diaphragm to pull in and partially

open the choke. As the engine continues to run, electric

current is supplied

to

the heating element. Heatfrom the

element causes the bi-metal strip to coil. The coiling

action of the bi-metal strip turns the choke

shaft

and

gradually opens the choke plate. Heat from the element

keeps the choke open while the engine is running.

The choke gets very hot during nor-

-1

mal operation and can cause severe

burns if touched.

Do

not

touch the choke assembly

during

and

after set operation.

Allow

the set to cool

down

before working on the choke assembly.

If

the engine starts but runs roughly and blowsout black

smoke after a minute or two of operation, the choke is

set

too

rich.

If

the engine starts but sputters or stops

before it warms up, the choke is set

too

lean.

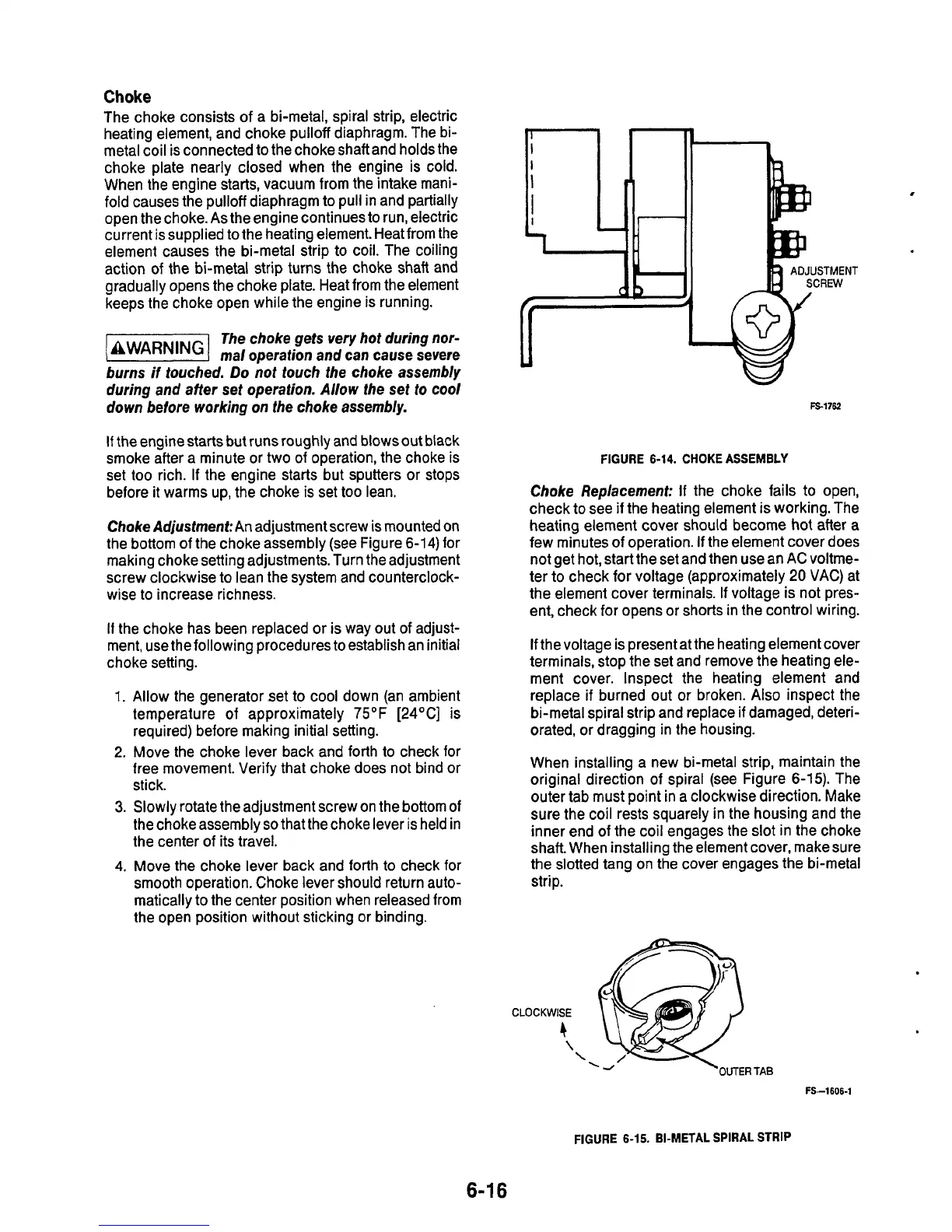

Choke Adjustment:

An adjustment screw

is

mounted on

the bottom

of

the choke assembly (see Figure

6-14)

for

making choke setting adjustments. Turn the adjustment

screw clockwise to lean the system and counterclock-

wise

to

increase richness.

If

the choke has been replaced

or

is way out of adjust-

ment, use the following procedures toestablish an initial

choke setting.

Allow the generator set

to

cool down (an ambient

temperature of approxi'mately

75°F

[24OC]

is

required) before making initial setting.

Move the choke lever back and forth

to

check for

free movement. Verify that choke does not bind

or

stick.

Slowly rotate the adjustment screw on the bottom of

the choke assembly

so

that the choke lever

is

held in

the center of its travel.

Move the choke lever back and forth to check for

smooth operation. Choke lever should return auto-

matically

to

the center position when released from

the open position without sticking

or

binding.

FS-1762

FIGURE

6-14. CHOKE ASSEMBLY

Choke Replacement:

If

the choke fails to open,

check

to

see

if

the heating element

is

working. The

heating element cover should become

hot

after a

few minutes of operation.

If

the element cover does

not get hot, start the set and then use an AC voltme-

ter to check for voltage (approximately

20

VAC) at

the element cover terminals.

If

voltage is not pres-

ent, check for opens or shorts in the control wiring.

If

the voltage is presentat the heating element cover

terminals, stop the set and remove the heating ele-

ment cover. Inspect the heating element and

replace

if

burned out or broken. Also inspect the

bi-metal spiral strip and replace if damaged, deteri-

orated,

or

dragging in the housing.

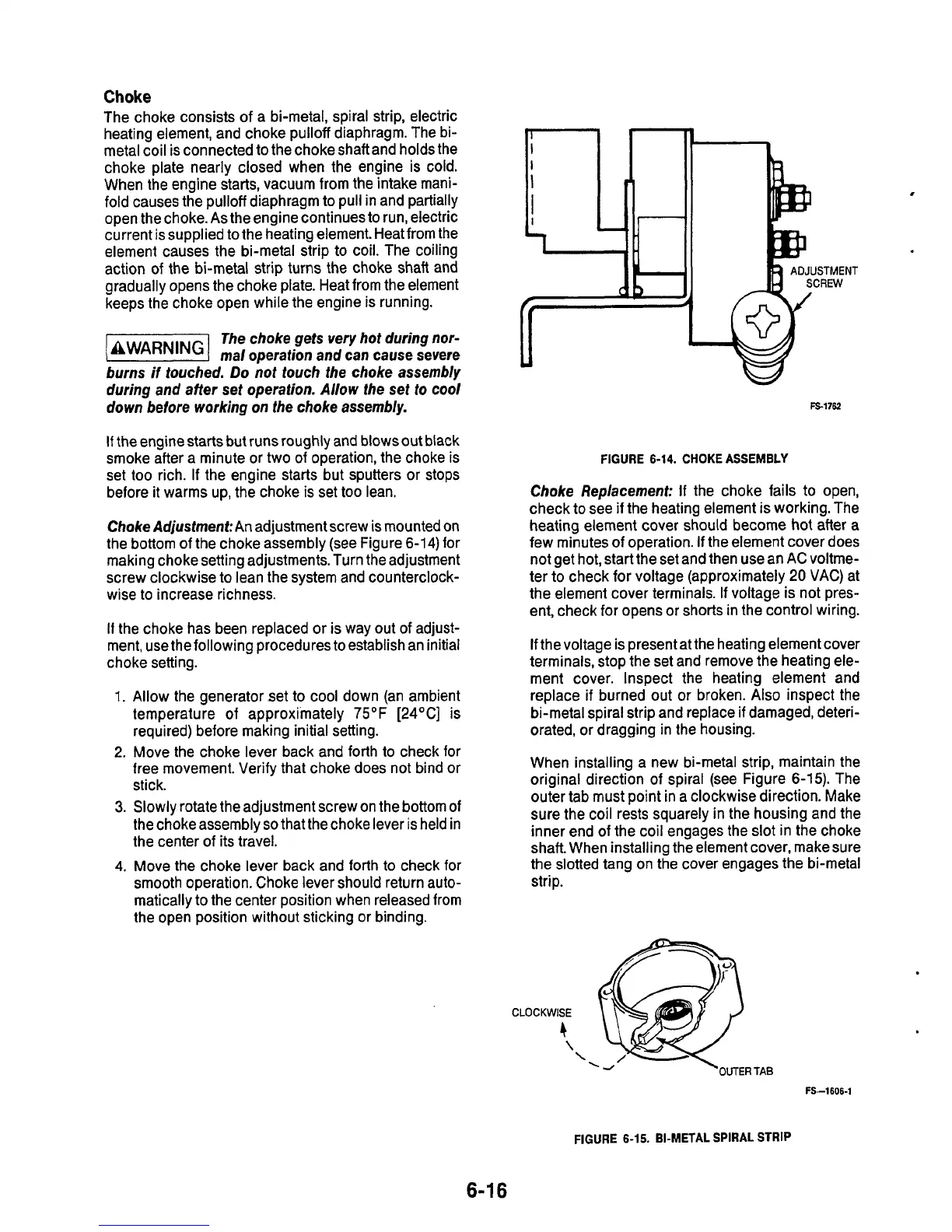

When installing a new bi-metal strip, maintain the

original direction

of

spiral (see Figure

6-15).

The

outer tab must point in a clockwise direction. Make

sure the coil rests squarely in the housing and the

inner end of the coil engages the

slot

in the choke

shaft. When installing the element cover, makesure

the slotted tang on the cover engages the bi-metal

strip.

CLOCKWISE

\

4

\.

,

OUTER

TAB

FS-1606-1

FIGURE

6-15. BI-METAL SPIRAL

STRIP

6-1

6

Loading...

Loading...