.

Regulator

Lock-off

Adjustment

The

regulator

lock-off

setting

is

used

to

set the valve

opening pressure. The lock-off can be checked and

adjusted as follows:

1.

Connect the regulator inlet (Figure

2)

to a source

of

air pressure regulated to

6

02.

(1

1

inches of water

column).

2.

Connect

a“T”

in

the balance line hose and connect

one leg of the

“T”

to an incline monometer that

reads from

0

to2 inches

of

water column. Connect a

hose to the other side of the

“T”.

3.

Put a soap bubble over the outlet opening of the

regulator. Lightly blow into the hose connected to

the

“T”

in the balance line. Slowly apply pressure

until the soap bubble continues to grow because of

air flowing through the regulator. Approximately

0.25

to

0.35

inchesof water column should causeair

to flow through the regulator. (When air is first blown

into the balance line the soap bubble may enlarge

due

to

diaphragm movement, this is not an indica-

tion that air is flowing through the regulator.

4.

If

more than

0.35

inches of water column pressure is

required

to

induce flow, loosen the lock nut on the

1

/4-28

lock-off adjusting screw, back out the screw

until air will flow in the

0.25

to

0.35

water column

pressure range.

If

air flows through the regulator

without any pressure being applied to the balance

line, the lock off adjustment screw must be turned in

to

increase spring pressure. When the proper set-

ting

is

achieved, hold the lock

off

adjusting screw in

position and tighten the locking nut. If adjustments

do not resolve problems see step

5.

5.

If

the inlet pressure is

too

high or

if

there is dirt on the

regulator inlet seat, the regulator will flow air even

though the adjusting screw is turned all the way in.

The regulatorshould not bedisassembled or repairs

attempted by anyone except the equipment manu-

facturer’s factory trained service technicians.

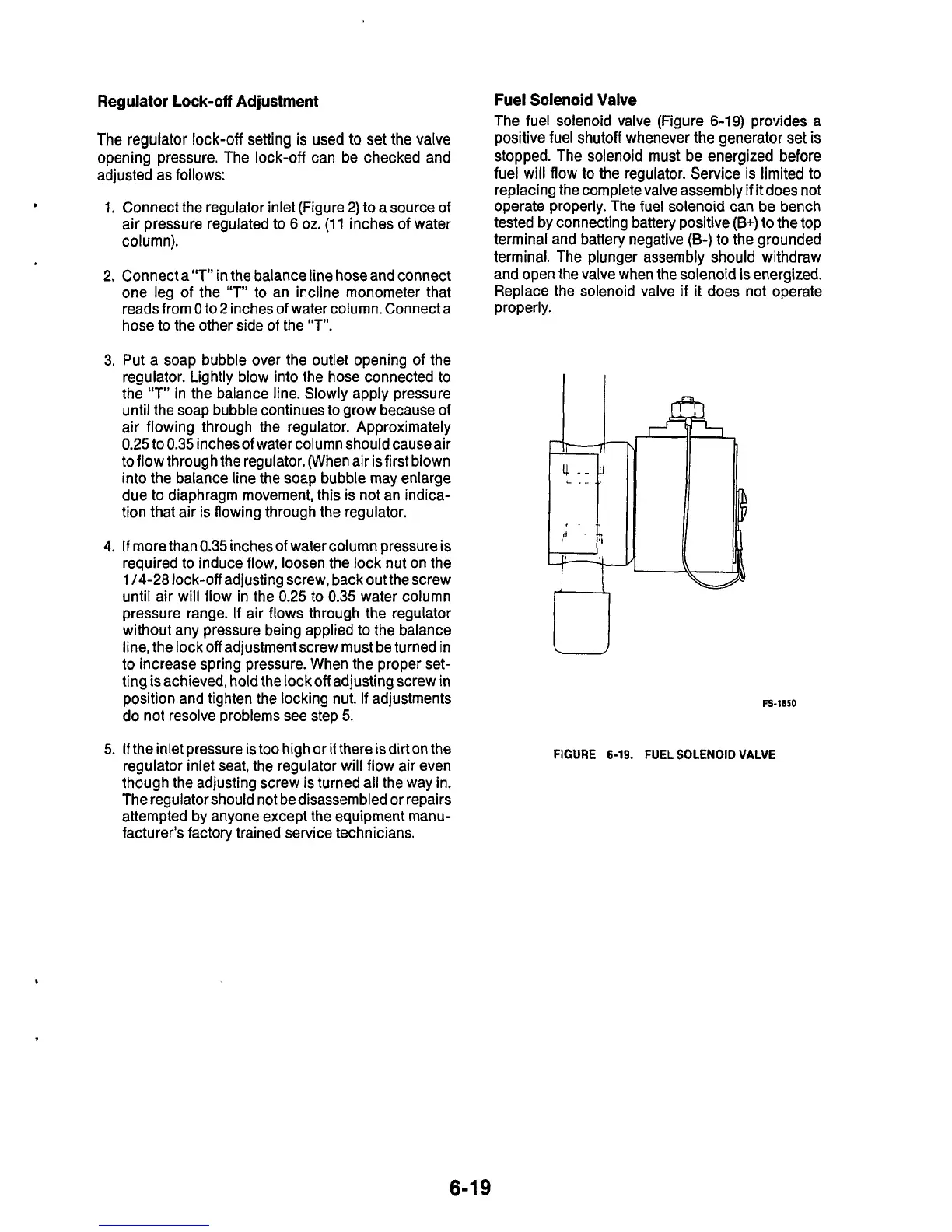

Fuel Solenoid Valve

The fuel solenoid valve (Figure

6-19)

provides a

positive fuel shutoff whenever the generator set

is

stopped. The solenoid must be energized before

fuel will flow

to

the regulator. Service is limited to

replacing the complete valve assembly

if

it

does not

operate properly. The fuel solenoid can be bench

tested by connecting battery positive

(B+)

to

the top

terminal and battery negative

(B-)

to

the grounded

terminal. The plunger assembly should withdraw

and open the valve when the solenoid is energized.

Replace the solenoid valve if

it

does not operate

properly.

I

I

U

FS-1850

FIGURE

6-19.

FUEL

SOLENOID

VALVE

6-1

9

Loading...

Loading...