LPG

Carburetor

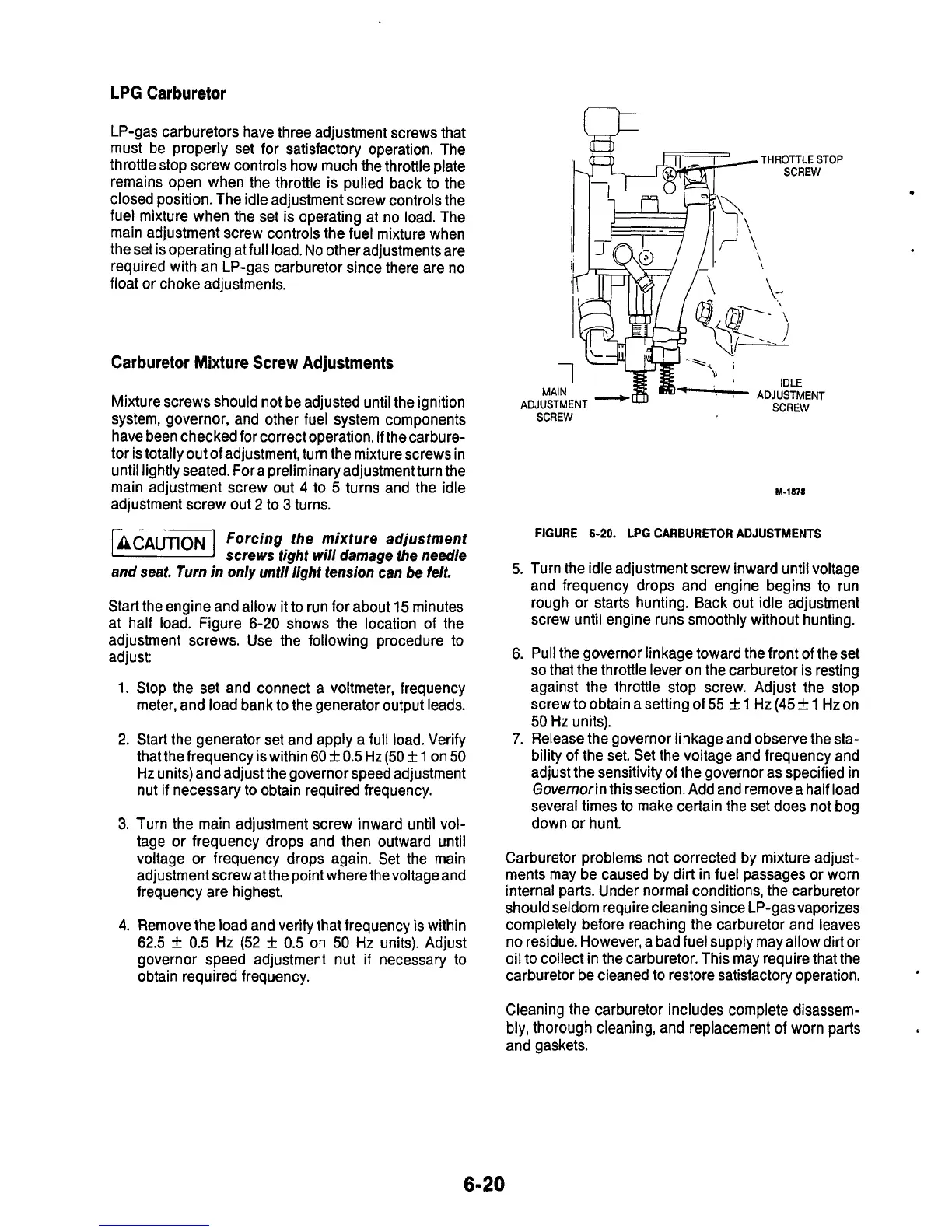

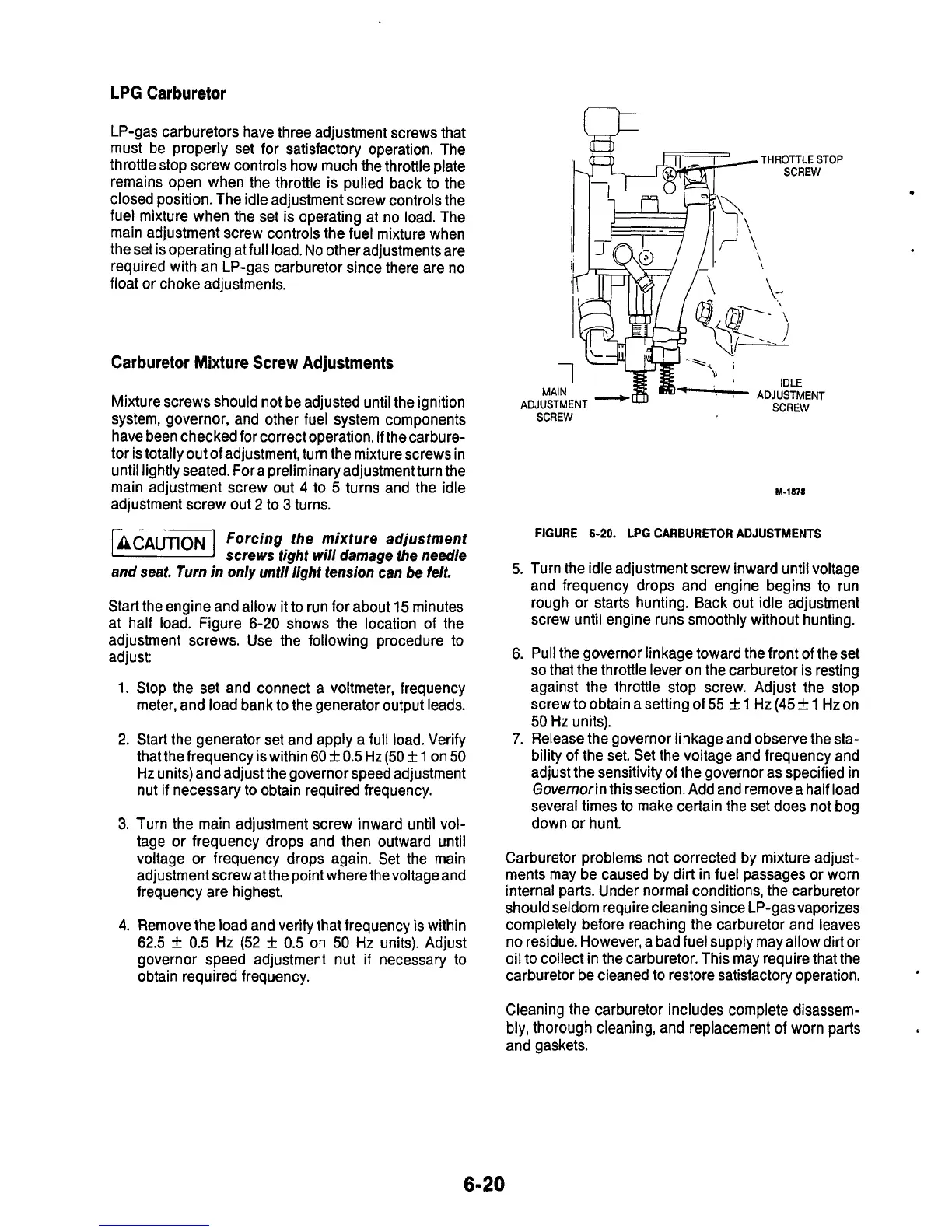

LP-gas carburetors have three adjustment screws that

must be properly set for satisfactory operation. The

throttle stop screw controls how much the throttle plate

remains open when the throttle is pulled back

to

the

closed position. The idle adjustment screw controls the

fuel mixture when the set is operating at no load. The

main adjustment screw controls the fuel mixture when

the set is operating at full load.

No

other adjustments are

required with an LP-gas carburetor since there are no

float or choke adjustments.

Carburetor Mixture Screw Adjustments

Mixture screws should not be adjusted until the ignition

system, governor, and other fuel system components

have been checked for correct operation.

If

thecarbure-

tor is totally out of adjustment, turn the mixture screws in

until lightly seated. Fora preliminary adjustment turn the

main adjustment screw out

4

to

5

turns and the idle

adjustment screw out 2 to

3

turns.

ACAUT~ON

Forcing the mixture adjustment

Ll.3

screws tight will damage the needle

and seat. Turn in only until light tension can be felt.

Start the engine and allow it to run for about

15

minutes

at half load. Figure 6-20 shows the location of the

adjustment screws. Use the following procedure to

adjust:

1.

Stop the set and connect

a

voltmeter, frequency

meter, and load bank

to

the generator output leads.

2.

Start the generator set and apply

a

full load. Verify

that the frequency

is

within

60

f

0.5

Hz

(50

f

1

on

50

Hz

units) and adjust the governor speed adjustment

nut if necessary to obtain required frequency.

3.

Turn the main adjustment screw inward until vol-

tage or frequency drops and then outward until

voltage or frequency drops again. Set the main

adjustment screw at the point where thevoltageand

frequency are highest.

4.

Remove the load and verify that frequency

is

within

62.5

f

0.5

Hz (52

f

0.5

on

50

Hz

units). Adjust

governor speed adjustment nut

if

necessary

to

obtain required frequency.

THROllLE STOP

-

ADJUSTMENT

SCREW

SCREW

M-1878

FIGURE

6-20.

LPG

CARBURETOR ADJUSTMENTS

5.

Turn the idle adjustment screw inward until voltage

and frequency drops and engine begins to run

rough

or

starts hunting. Back out idle adjustment

screw until engine runs smoothly without hunting.

6. Pull the governor linkage toward the front of the set

so

that the throttle lever on the carburetor is resting

against the throttle stop screw. Adjust the stop

screw to obtain a setting of

55

f

1

Hz

(45

f

1

Hz

on

50

Hz

units).

7.

Release the governor linkage and observe the sta-

bility

of

the set. Set the voltage and frequency and

adjust the sensitivity of the governor as specified in

Governor

in this section. Add and remove a half load

several times

to

make certain the set does not bog

down or hunt.

Carburetor problems not corrected by mixture adjust-

ments may be caused by dirt in fuel passages

or

worn

internal parts. Under normal conditions, the carburetor

should seldom require cleaning since LP-gas vaporizes

completely before reaching the carburetor and leaves

no residue. However, a bad fuel supply may allow dirt or

oil to collect in the carburetor. This may require that the

carburetor be cleaned

to

restore satisfactory operation.

Cleaning the carburetor includes complete disassem-

bly, thorough cleaning, and replacement

of

worn parts

and gaskets.

6-20

Loading...

Loading...