Installing Piston

in

Cylinder:

When installing the pis-

ton assembly, observe markings on the connecting rod,

cap,

and

splasher

and

assemble

in

correct position.

See

Figure

9-22.

3.

Tap piston down into bore with handle end of

hammer until connecting rod is seated on crankpin.

Check

crankpin

clearance

before

proceeding

to

#4

step (see Crankpin Clearance section).

1.

2.

+

Turn Crankshaft

to

position crankpin at bottom

of

its

stroke.

Lubricate piston assembly and inside

of

cylinder.

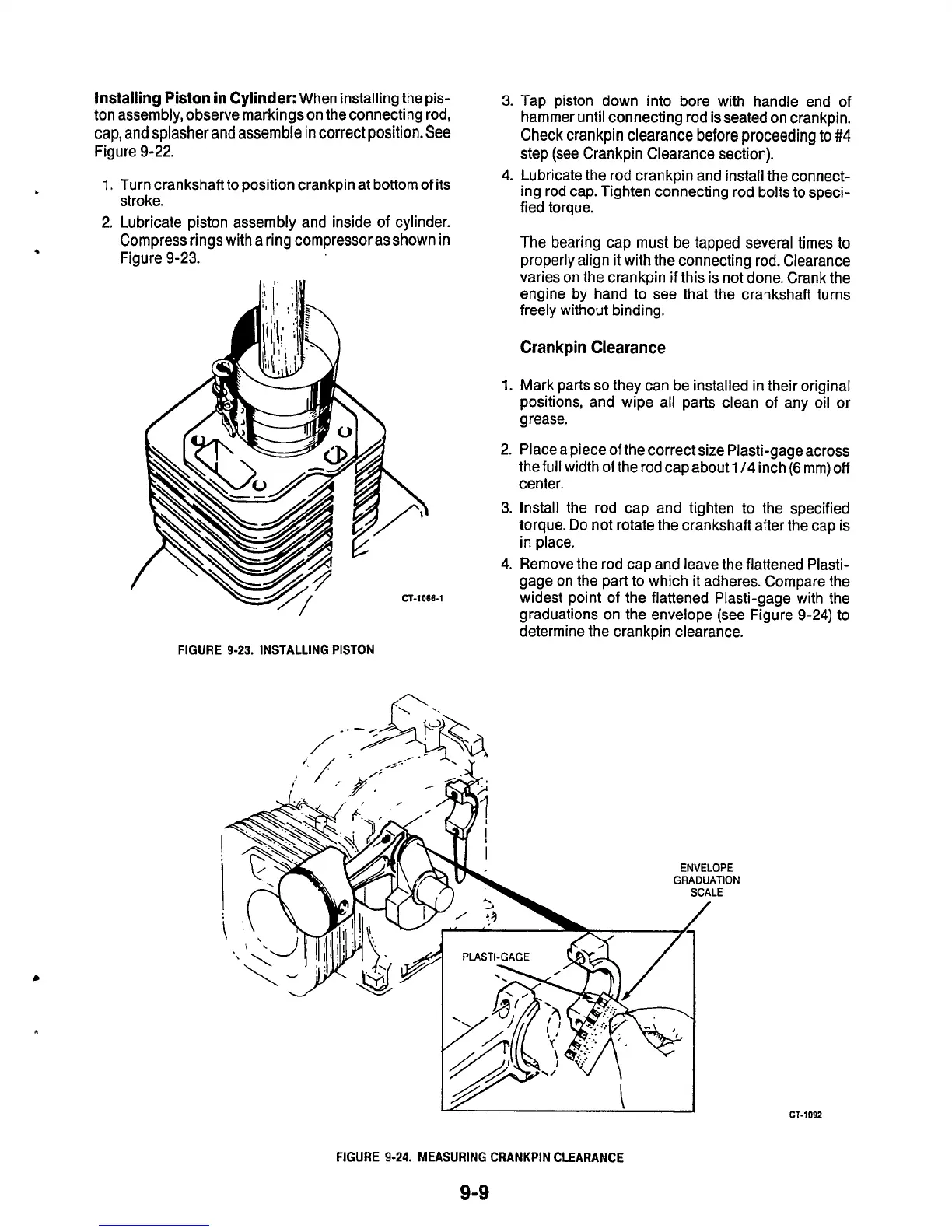

Compress rings with

a

ring compressor

as

shown

in

Figure

9-23.

4.

Lubricate the rod crankpin and install the connect-

ing rod cap. Tighten connecting rod bolts to speci-

fied torque.

The bearing cap must be tapped several times

to

properly align it with the connecting rod. Clearance

varies on the crankpin

if

this

is

not done. Crank the

engine by hand

to

see that the crankshaft turns

freely without binding.

Crankpin Clearance

1.

Mark parts

so

they can be installed in their original

positions, and wipe all parts clean of any oil or

grease.

2.

Place a piece of the correct size Plasti-gageacross

the full width

of

the rod cap about

1

/4

inch

(6

rnrn)

off

center.

3.

Install the rod cap and tighten to the specified

torque.

Do

not rotate the crankshaft after the cap is

in place.

4.

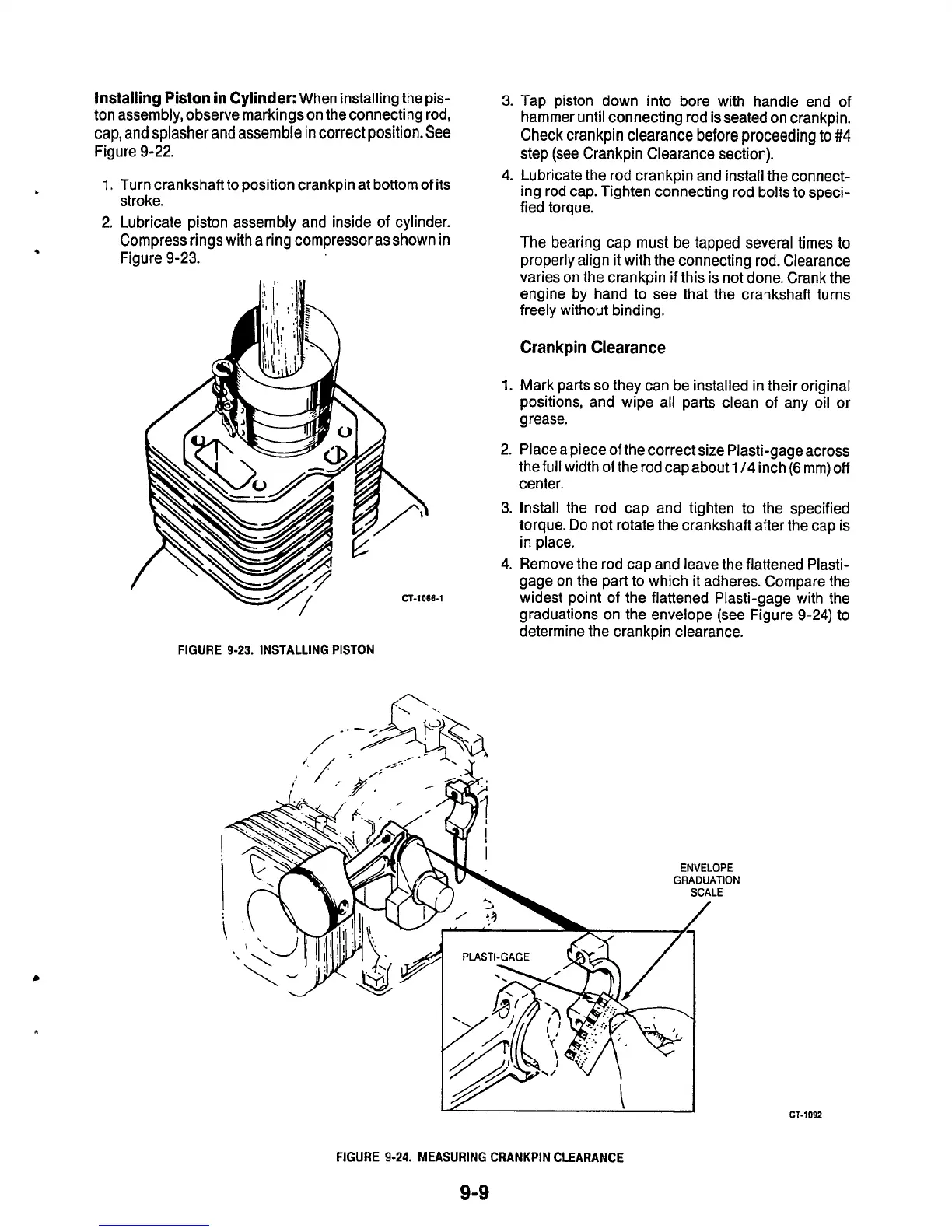

Remove the rod cap and leave the flattened Plasti-

gage on the part to which it adheres. Compare the

widest point of the flattened Plasti-gage with the

graduations on the envelope (see Figure

9-24)

to

determine the crankpin clearance.

FIGURE

9-23.

INSTALLING PISTON

FIGURE

9-24.

MEASURING CRANKPIN CLEARANCE

9-9

CT-1092

Loading...

Loading...