Use a new piston pin to check connecting rod for wear.

A

push fit clearance is required and varies from engine

to engine.

If

a new piston pin falls through a dry rod pin

bore as a result of its own weight, replace the rod or

bushing as required.

Piston

Pin

Inspection:

Replace piston pin that is

cracked, scored, or out of round more than 0.002 inch

(0.05

mm).

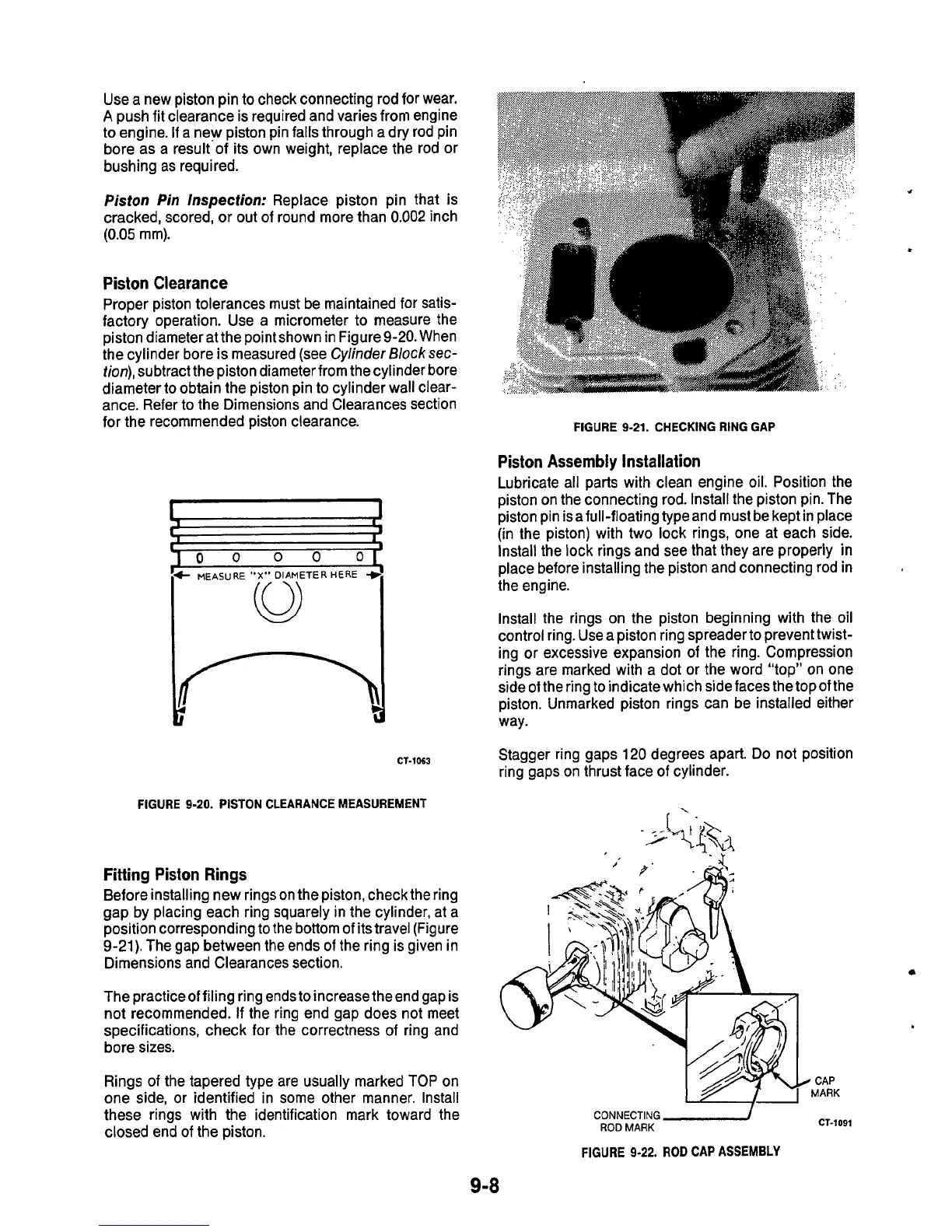

Piston Clearance

Proper piston tolerances must be maintained for satis-

factory operation. Use a micrometer to measure the

piston diameter at the pointshown in Figure9-20. When

the cylinder bore is measured (see Cylinder

Blocksec-

lion),

subtract the piston diameter from the cylinder bore

diameter to obtain the piston pin

to

cylinder wall clear-

ance. Refer to the Dimensions and Clearances section

for the recommended piston clearance.

CT-1063

FIGURE

9-20.

PISTON

CLEARANCE

MEASUREMENT

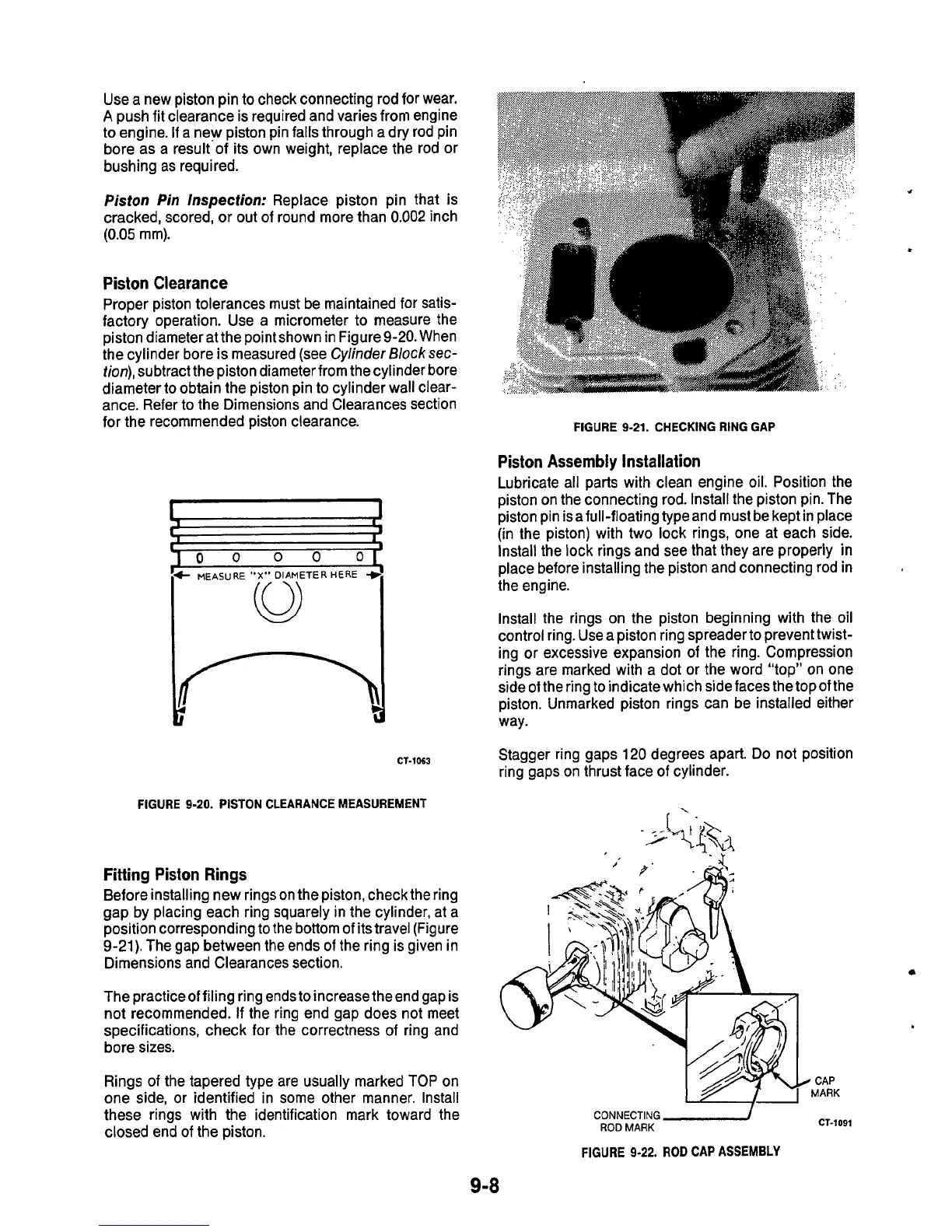

Fitting Piston Rings

Before installing new rings on the piston, check the ring

gap by placing each ring squarely in the cylinder, at a

position corresponding to the bottom of its travel (Figure

9-21). The gap between the ends of the ring is given in

Dimensions and Clearances section.

The practice of filing ring ends to increase the end gap is

not recommended.

If

the ring end gap does not meet

specifications, check for the correctness of ring and

bore sizes.

Rings of the tapered type are usually marked

TOP

on

one side, or identified in some other manner. Install

these rings with the identification mark toward the

closed end

of

the piston.

FIGURE

9-21.

CHECKING RING

GAP

Piston Assembly Installation

Lubricate all parts with clean engine oil. Position the

piston on the connecting rod. Install the piston pin. The

piston pin isafull-floating type and must be kept in place

(in the piston) with two lock rings, one at each side.

Install the lock rings and see that they are properly

in

place before installing the piston and connecting rod in

the engine.

Install the rings on the piston beginning with the

oil

control ring. Use a piston ring spreader to prevent twist-

ing or excessive expansion

of

the ring. Compression

rings are marked with a dot or the word "top" on one

side

of

the ring to indicate which side faces the top

of

the

piston. Unmarked piston rings can be installed either

way.

Stagger ring gaps 120 degrees apart. Do not position

ring gaps on thrust face of cylinder.

CONNECTING

-/

ROD

MARK

CT-1091

FIGURE

9-22.

ROD

CAP

ASSEMBLY

9-8

Loading...

Loading...