NOZZLE INSTALLATION

Before installing the injection nozzles in the engine,

thoroughly clean each mounting recess.

FIGURE

15.

INJECTION NOZZLE TESTER

Never use hard or sharp tools, emery

paper, grinding powder, or abrasives

of

any kind or the nozzles may be damaged beyond

use.

Soak each nozzle in fuel to loosen dirt. Then clean the

inside with a small strip of wood soaked in oil and the

spray hole with a wood splinter. If necessary, clean

the outer surfaces of the nozzle body with a brass

brush but do not attempt to scrape carbon from the

nozzle surfaces. This can severely damage the spray

hole. Use a soft oil-soaked rag or mutton tallow and

felt to clean the nozzle valve.

NOZZLE REPAIR

If cleaning will not eliminate a nozzle defect, replace

the nozzle or take it to an authorized diesel service

station.

Do

not attempt to replace parts of the nozzle

except for nozzle and pintle assembly.

Assembly

Rinse both valve and nozzle thoroughly before

assembly and coat with diesel fuel. The valve must be

free in the nozzle. Lift

it

about

1/3

out of the body.

It

should slide back to its seat without aid when the

assembly is held at a 45-degree angle.

If

necessary,

work the valve into its body with clean mutton tallow.

1.

2.

3.

4.

5.

Clamp nozzle holder body in a vise.

Set valve in body and set nozzle over

it.

Install nozzle cap nut loosely.

Place centering sleeve over nozzle for initial

tightening. Then remove centering sleeve to

prevent

it

from binding between nozzle and cap

nut.

Tighten nozzle cap nut to

50-55

ft.-lb. (68-75

Nom).

A

dirty mounting surface could permit blow-by,

causing nozzle failure and a resulting power

loss.

1.

Install a new heat shield to head gasket in cylinder

head recess.

2. Install heat shield, heat shield gasket, second

heat shield, and nozzle gasket.

3.

Insert nozzle assembly into recess.

Do

not strike

tip against any hard surface.

4.

Install nozzle flange and two cap screws. Tighten

cap screws alternately to avoid cocking nozzle

assembly. Tighten each to 20-21 foot-pounds (27-

28

Nom).

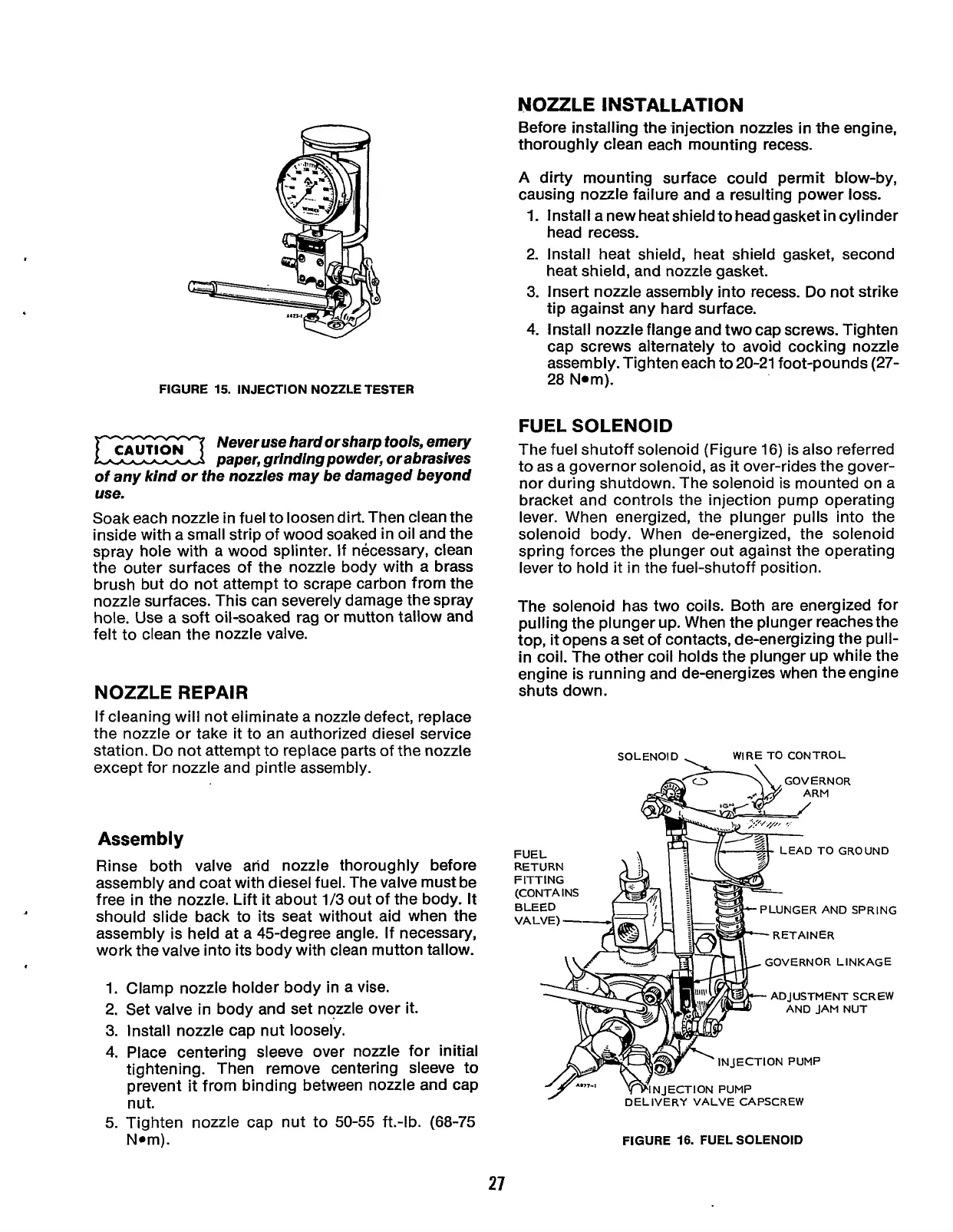

FUEL SOLENOID

The fuel shutoff solenoid (Figure 16) is also referred

to as a governor solenoid, as

it

over-rides the gover-

nor during shutdown. The solenoid

is

mounted on a

bracket and controls the injection pump operating

lever. When energized, the plunger pulls into the

solenoid body. When de-energized, the solenoid

spring forces the plunger out against the operating

lever to hold

it

in the fuel-shutoff position.

The solenoid has two coils. Both are energized for

pulling the plunger up. When the plunger reaches the

top,

it

opens a set of contacts, de-energizing the pull-

in coil. The other coil holds the plunger up while the

engine is running and de-energizes when the engine

shuts down.

SOLENOID

-

WIRE TO CONTROL

FUEL

D

TO GROUND

RETURN

FITTING

NGER AND SPRING

GOVERNOR LINKAGE

ADJUSTMENT SCREW

AND JAM NUT

INJECTION PUMP

N IECTION PUMP

DELIVERY

VALVE

CAPSCREW

0

FIGURE

16.

FUEL SOLENOID

21

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...