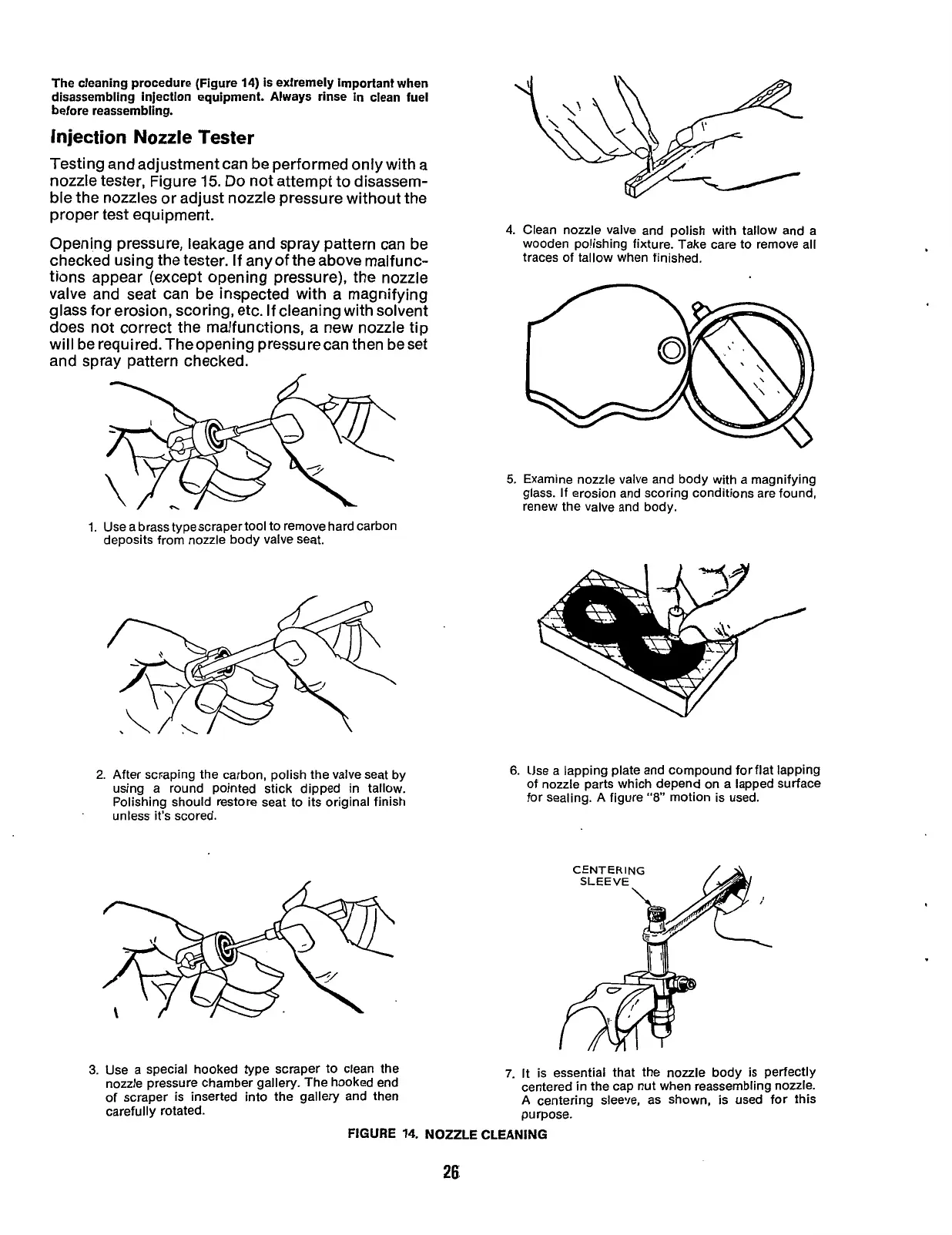

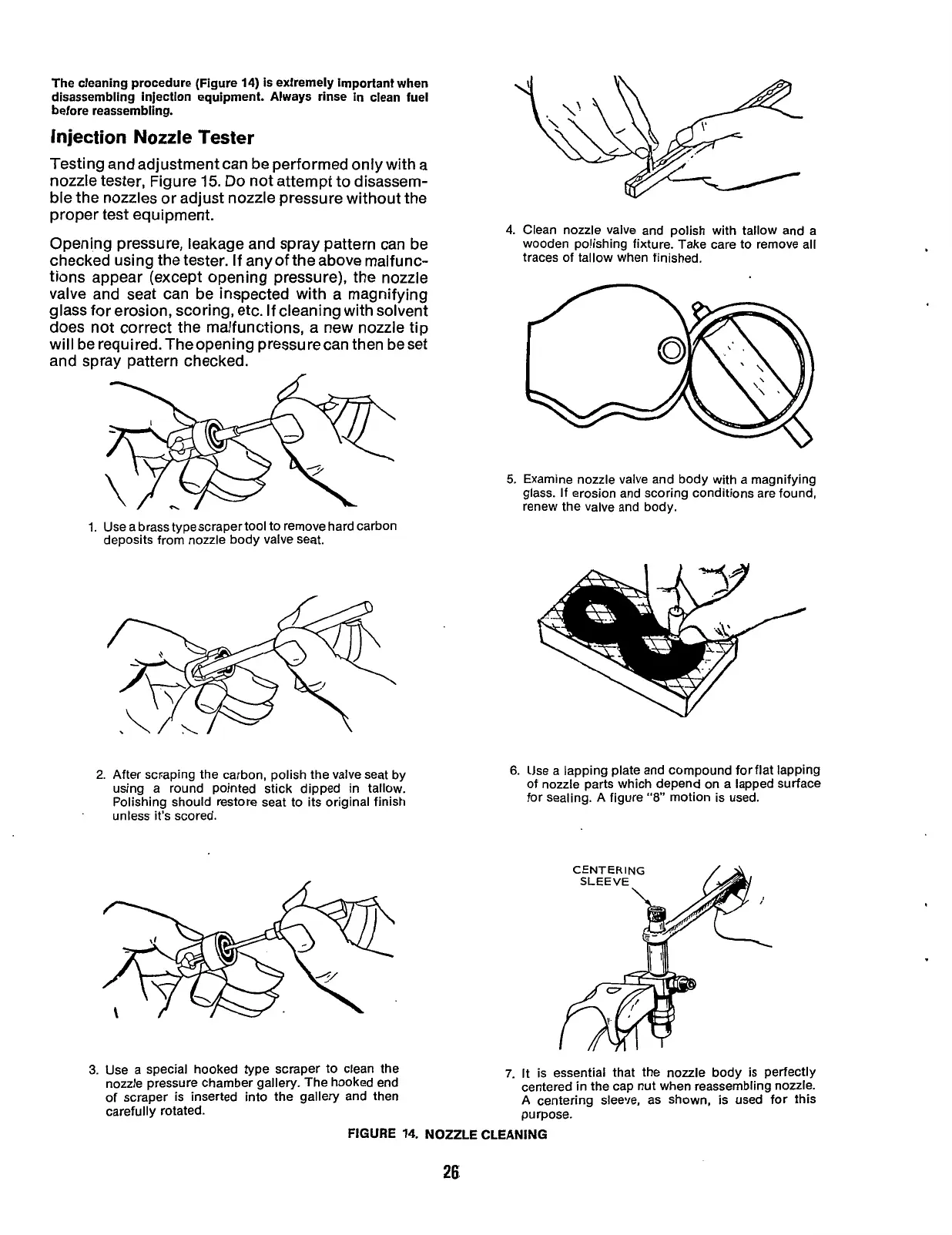

The cleaning procedure (Figure

14)

is extremely Important when

disassembling injection equipment. Always rinse

in

clean fuel

before reassembling.

Injection Nozzle Tester

Testing and adjustment can be performed only with a

nozzle tester, Figure

15.

Do

not attempt to disassem-

ble the nozzles or adjust nozzle pressure without the

proper test equipment.

Opening pressure, leakage and spray pattern can be

checked using the tester. If any of the above malfunc-

tions appear (except opening pressure), the nozzle

valve and seat can be inspected with a magnifying

glass for erosion, scoring, etc. If cleaning with solvent

does not correct the malfunctions, a new nozzle tip

will be required. Theopening pressure can then beset

and spray pattern checked.

1.

Use a brass type scraper tool to remove hard carbon

deposits from nozzle body valve seat.

2.

After scraping the carbon, polish the valve seat by

using a round pointed stick dipped in tallow.

Polishing should restore seat to its original finish

unless it’s scored.

4.

Clean nozzle valve and polish with tallow and a

wooden polishing fixture. Take care to remove all

traces of tallow when finished.

5.

Examine nozzle valve and body with a magnifying

glass.

If

erosion and scoring conditions are found,

renew the valve and body.

6.

Use a lapping plate and compound for flat lapping

of nozzle parts which depend on a lapped surface

for sealing. A figure

“8”

motion is used.

3.

Use a special hooked type scraper to clean the

nozzle pressure chamber gallery. The hooked end

of scraper is inserted into the gallery and then

carefully rotated.

7.

It is essential that the nozzle body is perfectly

centered in the cap nut when reassembling nozzle.

A

centering sleere, as shown, is used for !his

purpose.

FIGURE

14.

NOZZLE CLEANING

26

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...