2

3.

is injected

into

the pre-combustion chamber

GOOD

j5:l:

POOR

where

it

atomizes and mixes with the hot com-

If compression temperatures are high enough,

the fuel-air mixture ignites. Injection continues

SPRAY

PATTERN

7

Fuel enters fuel duct and pressure chamber of

nozzle assembly. When fuel pressure overcomes

preset pressure of the adjusting spring, the pintle

is

forced upward off itsseat and a fine mist of fuel

pressed air.

SPRA~TERN

::$!>

:.

,

;,!

i':..

..!

.

.I

.

;I..

,.

w.+

%-

.._

.bO7

until the spill port clears the top of the metering

sleeve

in

the injection pump and dumps the high

pressure fuel into the sump allowing the pressure

spring to close the injector and cut off fuel

injection to the cylinder.

Do

not disturb the injector pressure

adjusting screw; it cannot be reset

without proper equipment.

Bypass fuel is returned to the tank after each injection

cycle by a return line from the nozzle.

A

fuel return

fitting combines the return fuel from the injectors

with the flow-through fuel from the injection pump

bleed valve.

A

return line connected at this point

returns the combined fuel back to the fuel supply

tank.

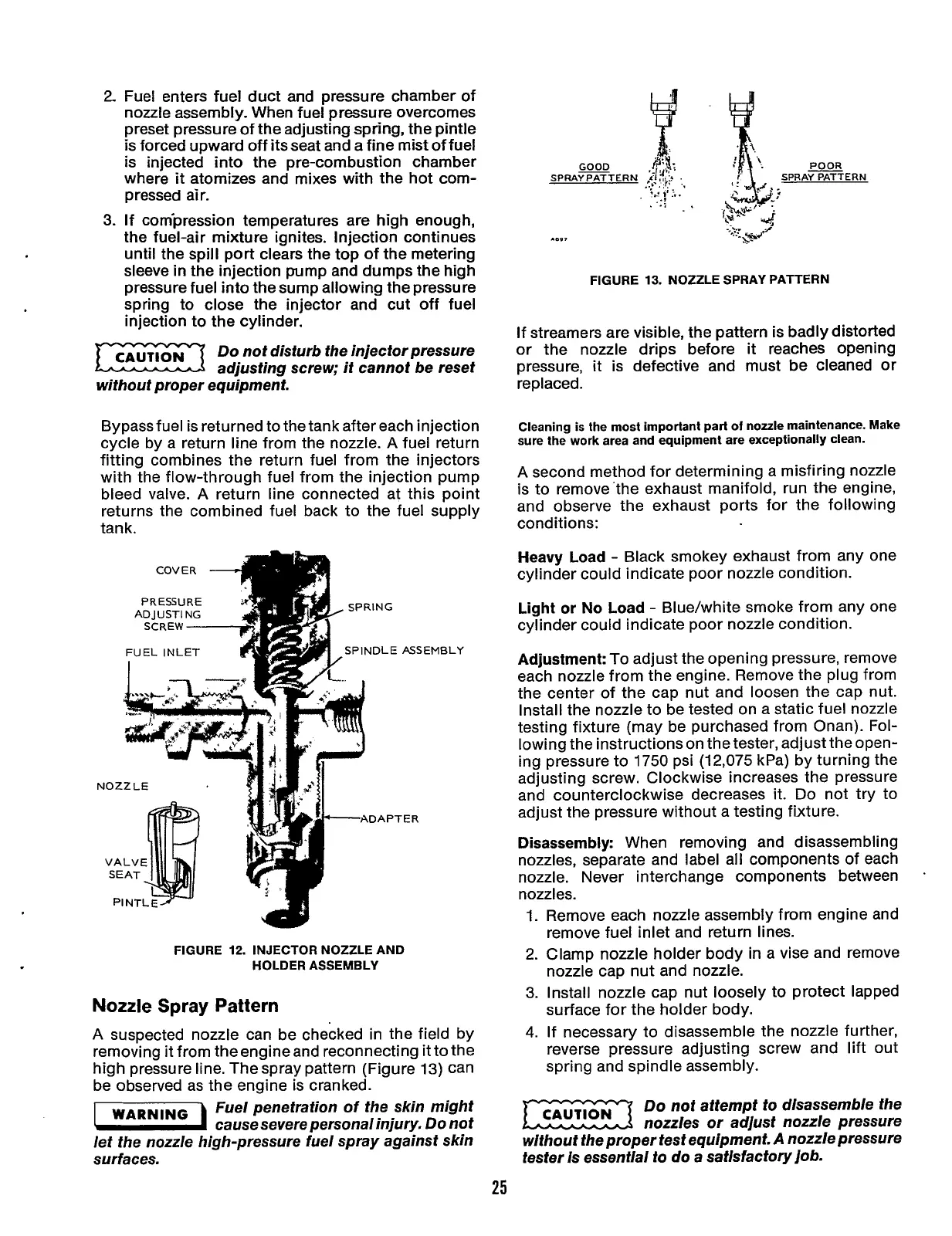

PRESSURE

FUEL INLET

VALVE^\^'

Z

SEAT

ADAPl

Ty

PINTLE

FIGURE

12.

INJECTOR NOZZLE AND

HOLDER ASSEMBLY

ASSEMBLY

-ER

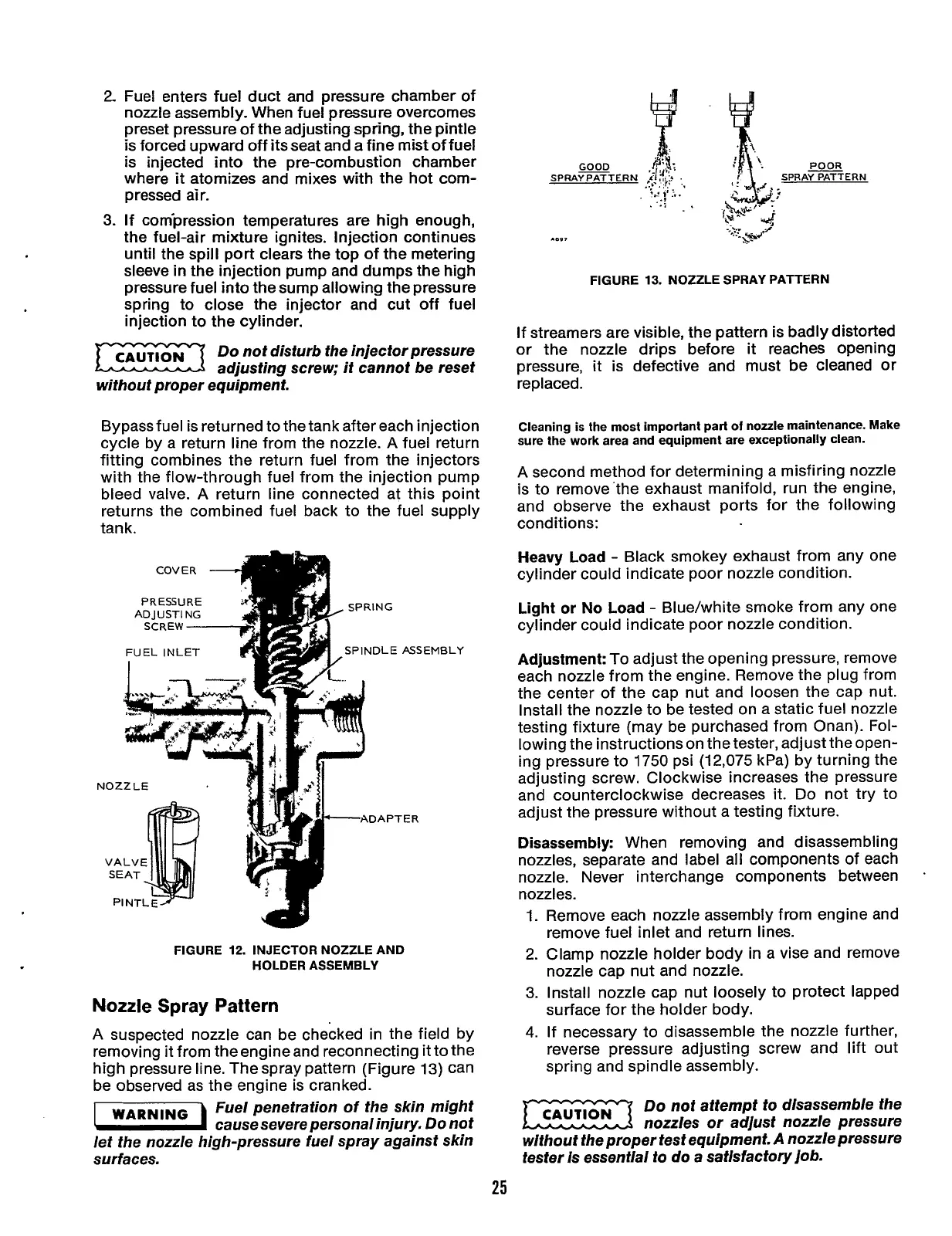

Nozzle Spray Pattern

A

suspected nozzle can be checked in the field by

removing

it

from theengineand reconnecting

it

to the

high pressure line. The spray pattern (Figure

13)

can

be observed as the engine is cranked.

Fuel penetrafion of the skin might

causesevere personalinjury.

Do

not

let the nozzle high-pressure fuel spray against skin

surfaces.

WARN,NG

FIGURE

13.

NOZZLE SPRAY PATTERN

If streamers are visible, the pattern is badly distorted

or the nozzle drips before

it

reaches opening

pressure, it is defective and must be cleaned or

replaced.

Cleaning

is

the most important part

of

nozzle maintenance. Make

sure the work area and equipment are exceptionally clean.

A

second method for determining a misfiring nozzle

is to remove'the exhaust manifold, run the engine,

and observe the exhaust ports for the following

conditions:

Heavy Load

-

Black smokey exhaust from any one

cylinder could indicate poor nozzle condition.

Light

or

No

Load

-

Blue/white smoke from any one

cylinder could indicate poor nozzle condition.

Adjustment:

To adjust the opening pressure, remove

each nozzle from the engine. Remove the plug from

the center of the cap nut and loosen the cap nut.

Install the nozzle to be tested on a static fuel nozzle

testing fixture (may be purchased from Onan). Fol-

lowing the instructions on the tester, adjust the open-

ing pressure to

1750

psi

(12,075

kPa) by turning the

adjusting screw. Clockwise increases the pressure

and counterclockwise decreases

it.

Do

not try to

adjust the pressure without a testing fixture.

Disassembly:

When removing and disassembling

nozzles, separate and label all components of each

nozzle. Never interchange components between

*

nozzles.

1.

Remove each nozzle assembly from engine and

remove fuel inlet and return lines.

2.

Clamp nozzle holder body

in

a vise and remove

nozzle cap nut and nozzle.

3.

Install nozzle cap nut loosely to protect lapped

surface for the holder body.

4.

If necessary to disassemble the nozzle further,

reverse pressure adjusting screw and lift out

spring and spindle assembly.

Do

not attempt to disassemble the

nozzles or adjust nozzle pressure

without the proper test equipment.

A

nozzle pressure

tester is essential to do a satlsfactorylob.

25

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...