Assembly:

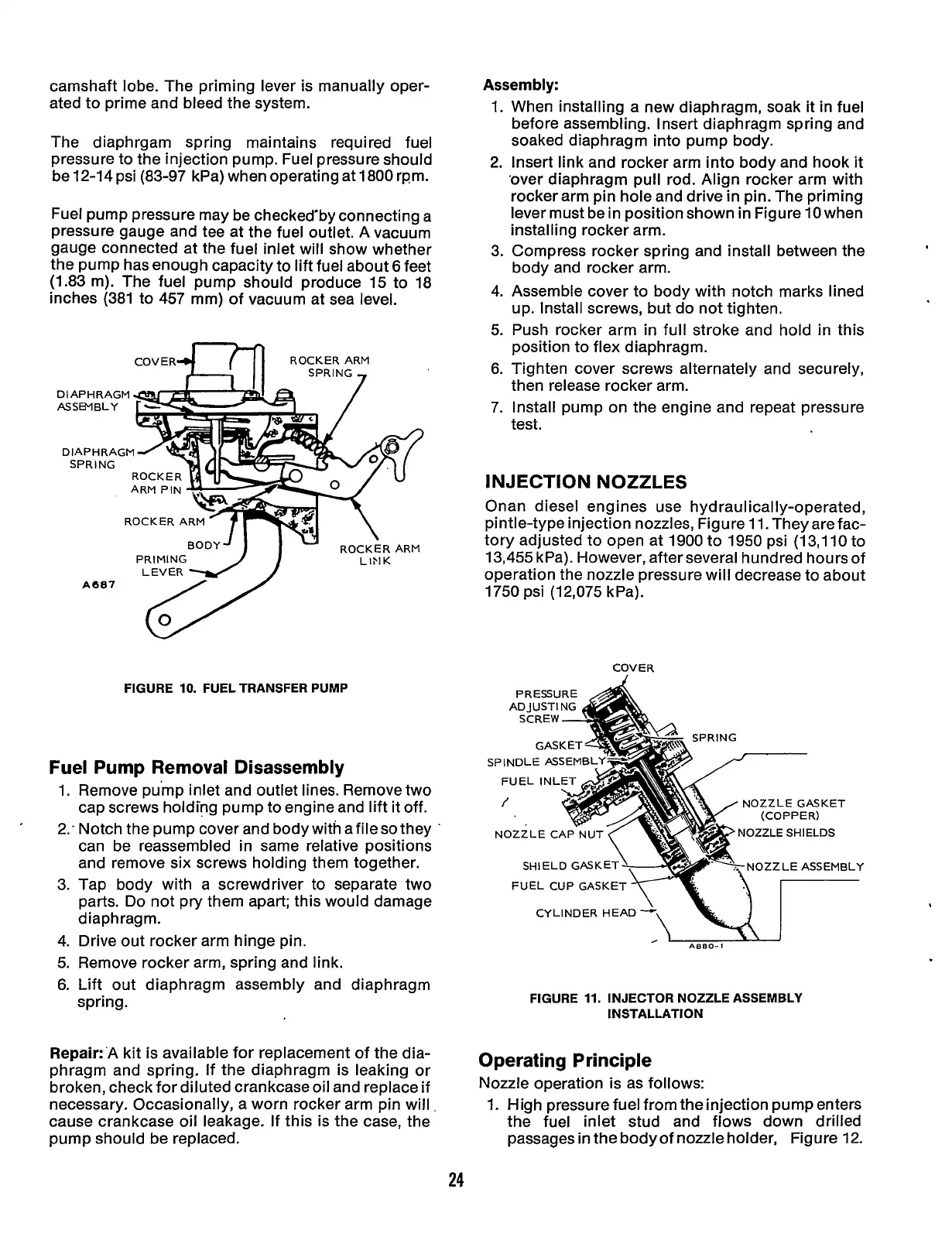

camshaft lobe. The priming lever is manually oper-

ated to prime and bleed the system.

The diaphrgam spring maintains required fuel

pressure to the injection pump. Fuel pressure should

be 12-14 psi (83-97 kPa) when operating at 1800 rpm.

Fuel pump pressure may be checked'by connecting a

pressure gauge and tee at the fuel outlet. A vacuum

gauge connected at the fuel inlet will show whether

the pump has enough capacity to lift fuel about

6

feet

(1.83 m). The fuel pump should produce

15

to 18

inches (381 to 457 mm) of vacuum at sea level.

ROCKER ARM

SPRING

.,

COVER

DlAPHRAGl

SPRINT.

PRIMING LiFlK

FIGURE

10.

FUEL TRANSFER PUMP

Fuel Pump Removal Disassembly

1.

Remove pump inlet and outlet lines. Remove two

cap screws holding pump to engine and lift it off.

2: Notch the pump cover and body with afileso they

'

3.

4.

5.

6.

can be reassembled in same-relative positions

and remove six screws holding them together.

Tap body with a screwdriver to separate two

parts. Do not pry them apart; this would damage

d ia p

h

rag m.

Drive out rocker arm hinge pin.

Remove rocker arm, spring and link.

Lift out diaphragm assembly and diaphragm

spring.

Repair:'A kit is available for replacement of the dia-

phragm and spring. If the diaphragm is leaking or

broken, check for diluted crankcase oil and replace if

necessary. Occasionally, a worn rocker arm pin will

cause crankcase oil leakage.

If

this is the case, the

pump should be replaced.

1.

2.

3.

4.

5.

6.

7.

When installing a new diaphragm, soak it in fuel

before assembling. Insert diaphragm spring and

soaked diaphragm into pump body.

Insert link and rocker arm into body and hook it

'over diaphragm pull rod. Align rocker arm with

rocker arm pin hole and drive

in

pin. The priming

lever must be

in

position shown in Figure

10

when

installing rocker arm.

Compress rocker spring and install between the

body and rocker arm.

Assemble cover to body with notch marks lined

up. Install screws, but do not tighten.

Push rocker arm

in

full stroke and hold in this

position to flex diaphragm.

Tighten cover screws alternately and securely,

then release rocker arm.

Install pump on the engine and repeat pressure

test.

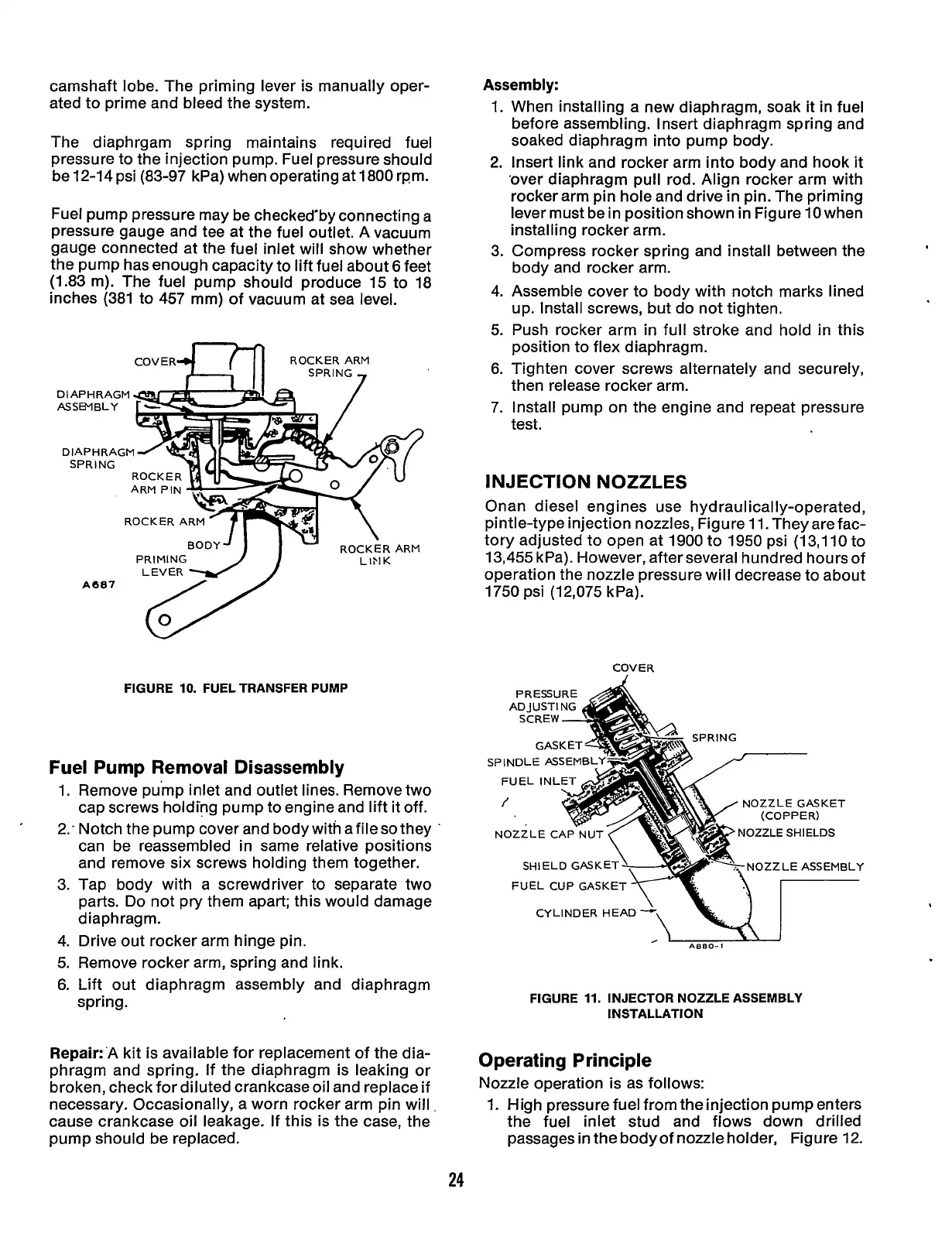

INJECTION NOZZLES

Onan diesel engines use hydraulically-operated,

pintle-type injection nozzles, Figure

11.

They arefac-

tory adjusted to open at 1900 to 1950 psi

(13,110

to

13,455 kPa). However, after several hundred hours of

operation the nozzle pressure will decrease to about

1750

psi

(1

2,075

k Pa).

COVER

SPINDLE ASSEM

NOZZLE GASKET

NOZZLE CA

OZZLE

SHIELDS

OZZLE ASSEMBLY SHIELD CASK

FUEL CUP GASKET

CYLINDER HEAD

,-

A880-1

FIGURE

11.

INJECTOR NOZZLE ASSEMBLY

INSTALLATION

Operating Principle

Nozzle operation is as follows:

1.

High pressure fuel from the injection pump enters

the fuel inlet stud and flows down drilled

passages

in

the body

of

nozzle holder, Figure 12.

24

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...