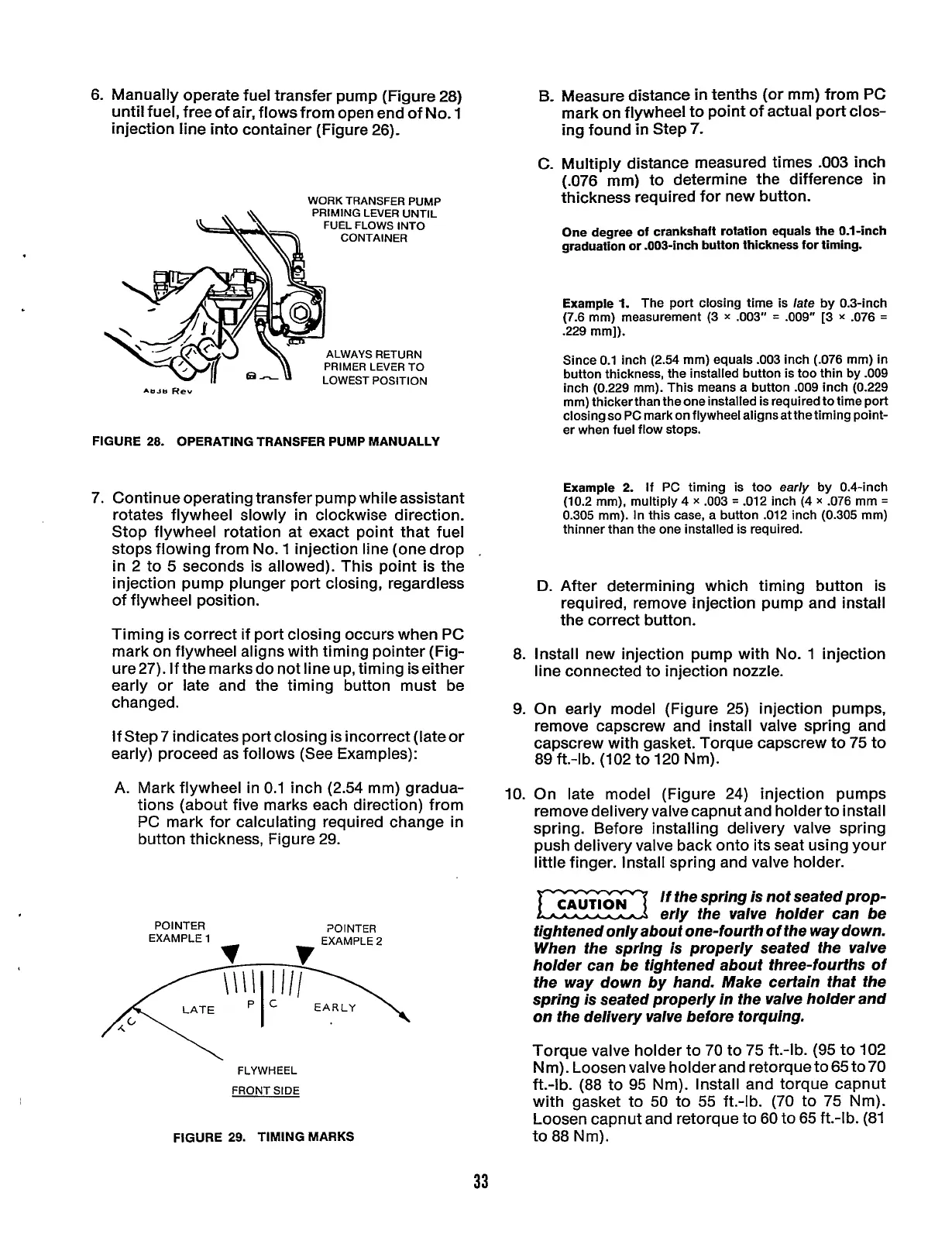

6. Manually operate fuel transfer pump (Figure 28)

until fuel, free of air, flows from open end of

No.

1

injection line into container (Figure 26)-

WORK TRANSFER PUMP

PRIMING LEVER UNTIL

FUEL FLOWS INTO

CONTAINER

ALWAYS RETURN

PRIMER LEVER TO

LOWEST POSITION

AUJU

Rev

FIGURE

28.

OPERATING TRANSFER PUMP MANUALLY

7

Continue operating transfer pump while assistant

rotates flywheel slowly in clockwise direction.

Stop flywheel rotation at exact point that fuel

stops flowing from No.

I

injection line (one drop

in 2 to

5

seconds is allowed). This point is the

injection pump plunger port closing, regardless

of flywheel position.

Timing is correct

if

port closing occurs when PC

mark on flywheel aligns with timing pointer (Fig-

ure27).

If

the marks do not line up, timing is either

early or late and the timing button must be

changed.

If Step

7

indicates port closing is incorrect (lateor

early) proceed as follows (See Examples):

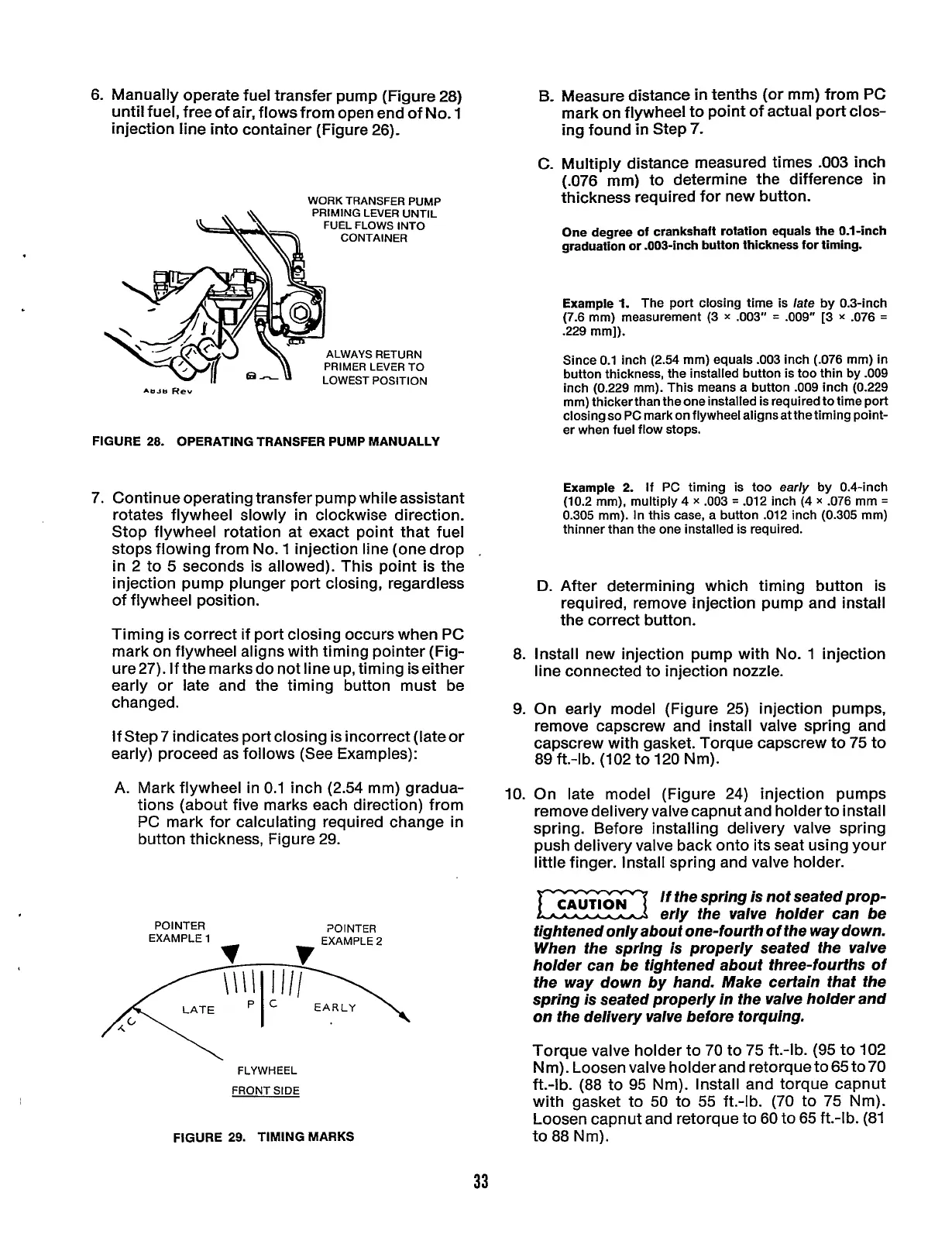

A.

Mark flywheel in

0.1

inch (2.54 mm) gradua-

tions (about five marks each direction) from

PC mark for calculating required change in

button thickness, Figure 29.

POINTER

?OINTER

EXAMPLE

1

EXAMPLE

2

FLYWHEEL

FRONT SIDE

FIGURE

29.

TIMING

MARKS

8.

9.

10.

B.

C.

D.

Measure distance

in

tenths (or mm) from PC

mark on flywheel to point of actual port clos-

ing found in Step

7.

Multiply distance measured times

.003

inch

(-076 mm) to determine the difference in

thickness required for new button.

One degree of crankshaft rotation equals the 0.1-inch

graduation or .OO&inch button thickness for timing.

Example

1.

The port closing time is /ate by 0.3-inch

(7.6 mm) measurement (3

x

.003"

=

.009"

[3

x

.076

=

.229 mm]).

Since

0.1

inch (2.54 mm) equals .003 inch (.076 mm)

in

button thickness, the installed button is too

thin

by -009

inch (0.229 mm). This means a button

.009

inch (0.229

mm) thickerthan the one installed is required

to

time port

closing

so

PC

mark on flywheel alignsat the timing point-

er when fuel flow stops.

Example

2.

If

PC

timing is too ear/y by 0.4-inch

(10.2 mm), multiply

4

x

.003

=

.012 inch (4

x

.076 mm

=

0.305 mm). In this case, a button .012 inch (0.305 mm)

thinner than the one installed is required.

After determining which timing button is

required, remove injection pump and install

the correct button.

Install new injection pump with No.

1

injection

line connected to injection nozzle.

On early model (Figure 25) injection pumps,

remove capscrew and install valve spring and

capscrew with gasket. Torque capscrew to

75

to

89 ft.-lb. (102 to 120 Nm).

On late model (Figure 24) injection pumps

remove delivery valve capnut and holder to install

spring. Before installing delivery valve spring

push delivery valve back onto its seat using your

little finger. Install spring and valve holder.

If the spring is not seated prop-

erly the valve holder can be

tightened on/y about one-fourth of the way down.

When the spring

is

properly seated the valve

holder can be tightened about three-fourfhs of

the way down by hand. Make cerfain that the

spring is seated properly in the valve holder and

on the delivery valve before torquing.

Torque valve holder to

70

to 75 ft.-lb. (95 to 102

Nm). Loosen valve holder and retorque to

65

to 70

ft.-lb.

(88

to 95 Nm). Install and torque capnut

with gasket to

50

to

55

it.-lb.

(70

to

75

Nm).

Loosen capnut and retorque to

60

to

65

ft.-lb.

(81

to

88

Nm).

33

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...