INJECTION

PUMP

INSTALLATION

Be sure the steel shims between the pump and the

cylinder block mounting are the same. These shims

maintain proper gear backlash. The number stamped

on the cylinder block injection pump mounting pad

indicates the proper shim thickness. This thickness

does not change when a new pump is installed. It only

changes when a new cylinder block is installed.

1.

Turn engine in direction of rotation (clockwise

when viewed from the front of engine) until

number one cylinder is on a compression stroke

and the

PC

mark on flywheel lines up with timing

pointer on gearcase (Figure 27). Rotation clock-

wise also takes out all gear backlash in that

direction.

Look into injection pump mounting hole to verify

that one intake lobe points outward and down

45

degrees.

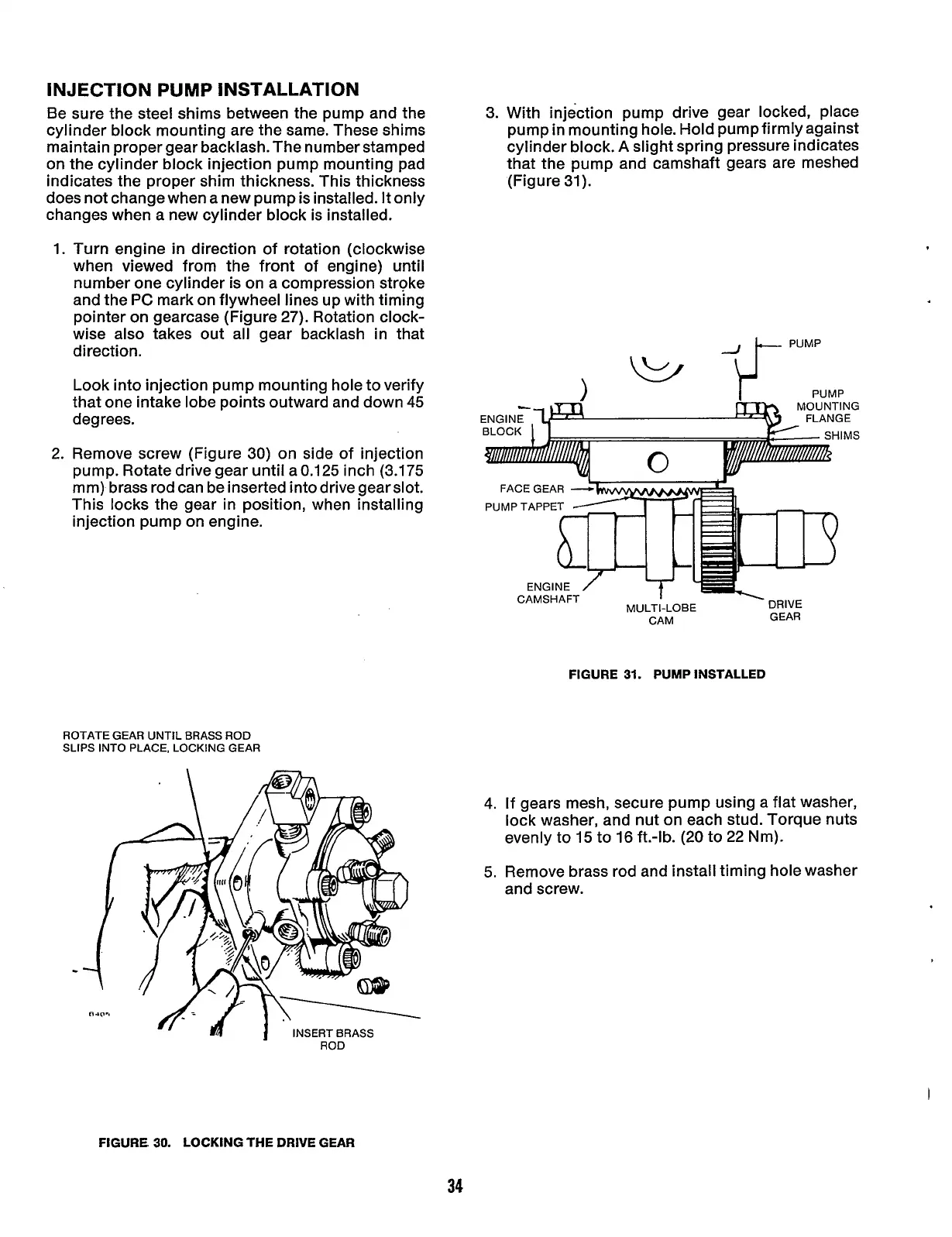

2.

Remove screw (Figure

30)

on side of injection

pump. Rotate drive gear until a 0.125 inch (3.175

mrn) brass rod can be inserted into drive gearslot.

This locks the gear in position, when installing

injection pump on engine.

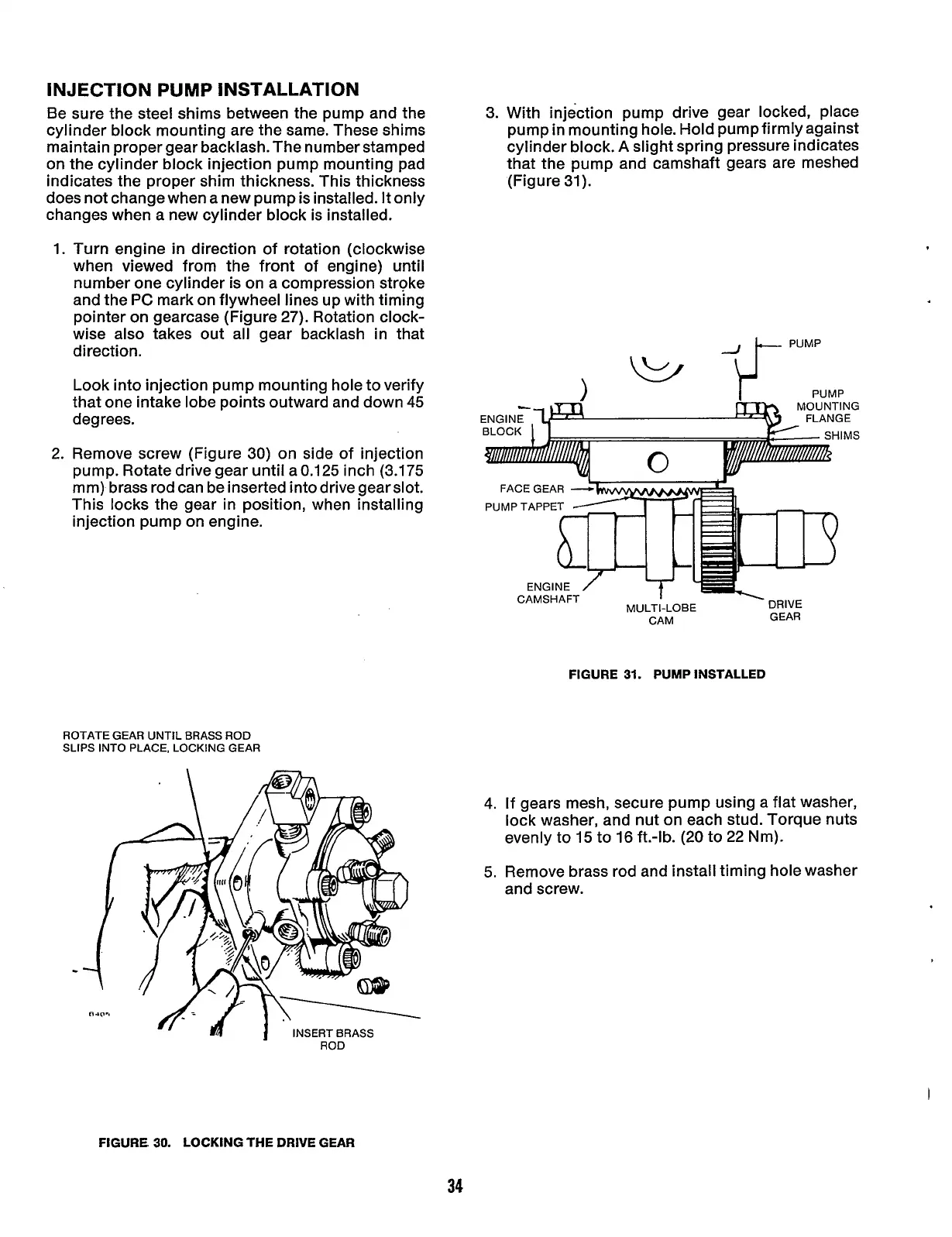

3. With injection pump drive gear locked, place

pump in mounting hole. Hold pump firmly against

cylinder block.

A

slight spring pressure indicates

that the pump and camshaft gears are meshed

(Figure 31).

PUMP

MOUNTING

m

1

ENGINE

/

Lf'

..I I,

7,

I

nnr

CAMSHAFT

IVlUL

I

I-LUPC

CAM GEAR

FIGURE

31.

PUMP

INSTALLED

ROTATE GEAR UNTIL BRASS

ROD

SLIPS INTO PLACE, LOCKING GEAR

ROD

FIGURE

30.

LOCKING THE DRIVE GEAR

4.

If gears mesh, secure pump using a flat washer,

lock washer, and nut on each stud. Torque nuts

evenly to

15

to 16 ft.-lb.

(20

to 22 Nm).

5.

Remove brass rod and install timing hole washer

and screw.

34

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...