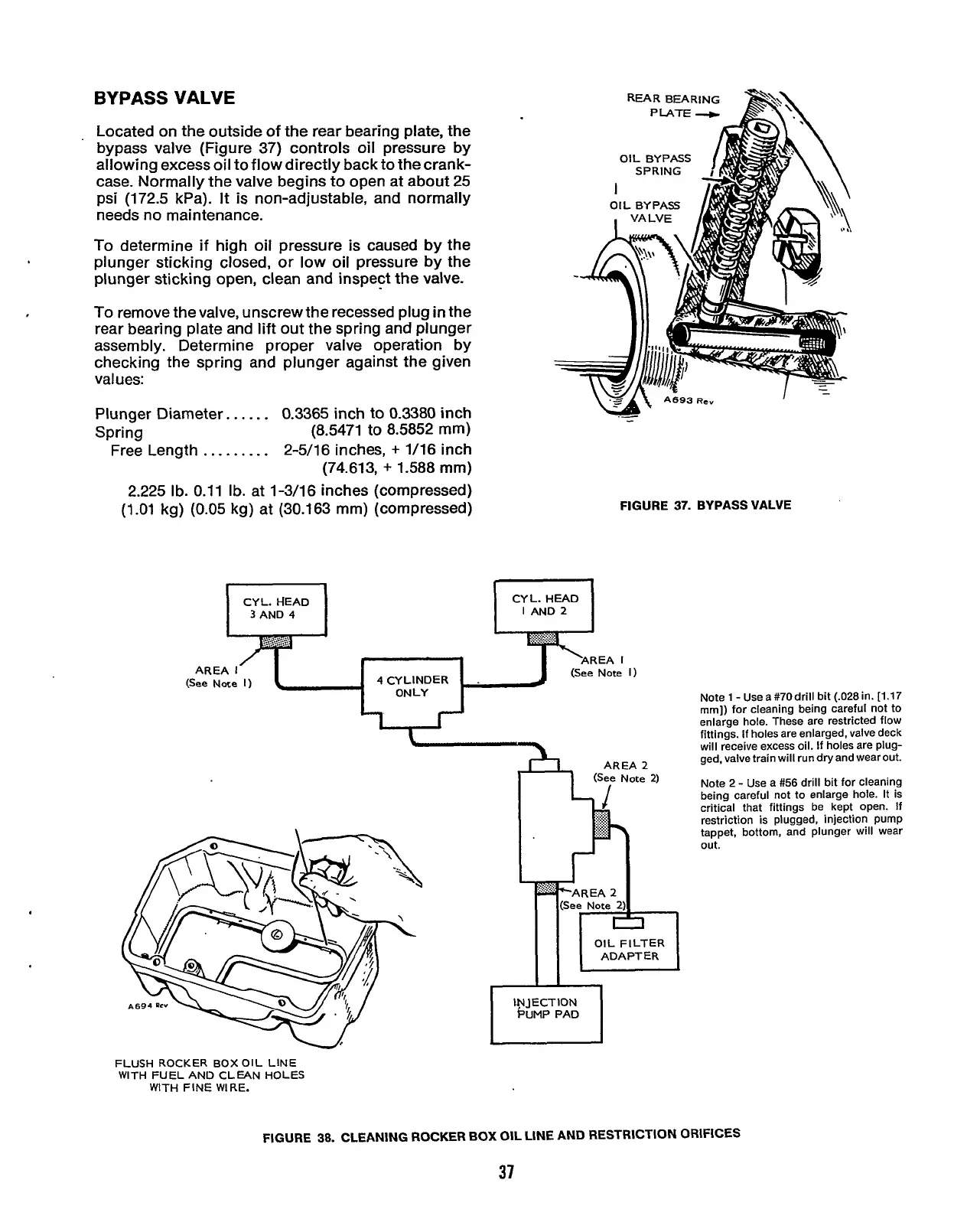

BYPASSVALVE

Located on the outside of the rear bearing plate, the

bypass valve (Figure

37)

controls oil pressure

by

allowing excess oil to flow directly back to the crank-

case. Normally the valve begins to open at about 25

psi (172.5 kPa).

It

is

non-adjustable, and normally

needs no maintenance.

To

determine

if

high oil pressure is caused

by

the

plunger sticking closed,

or

low oil pressure

by

the

plunger sticking open, clean and inspect the valve.

To

remove the valve, unscrew the recessed plug

in

the

rear bearing plate and lift out the spring and plunger

assembly. Determine proper valve operation by

checking the spring and plunger against the given

values:

Plunger Diameter..

....

0.3365 inch to 0.3380 inch

Spring (8.5471 to 8.5852

mm)

Free Length

.........

2-5/16 inches,

+

1/16 inch

(74.613,

+

1.588

mm)

2.225 Ib. 0.11

Ib.

at 1-3/16 inches (compressed)

(1.01 kg)

(0.05

kg) at (30.163 mm) (compressed)

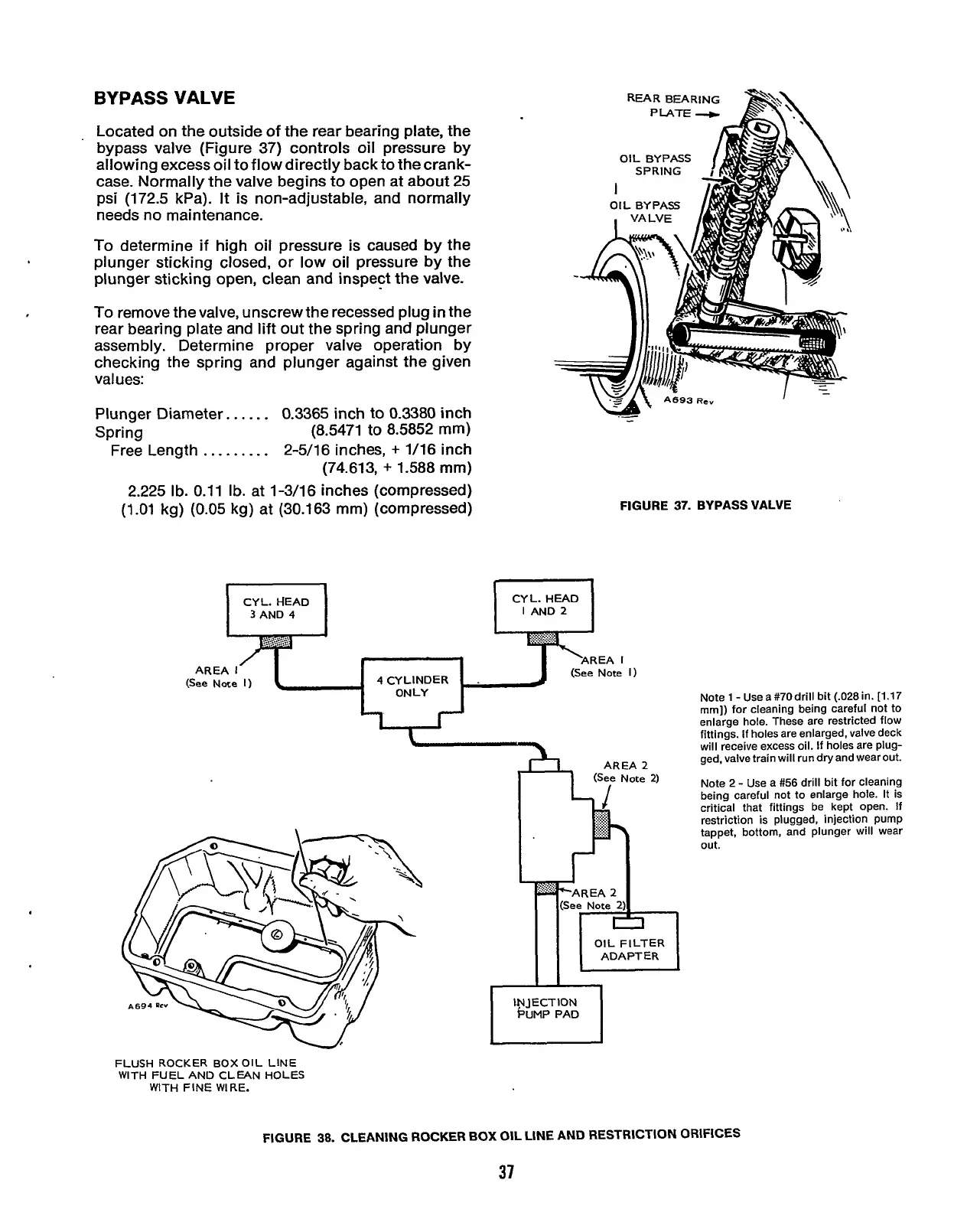

CYL. HEAD

3

AND

4

REAR

BEARING

OIL BYPASS

OIL BYPASS

-

FIGURE

37.

BYPASS

VALVE

CYL. HEAD

I

AND

2

AREA

I

(See Note

I)

(See Note

1)

4

CYLINDER

FLUSH ROCKER BOX OIL LINE

WITH FUEL AND CLEAN HOLES

WITH FINE WIRE.

INJECTION

PUMP PAD

Note1 -Usea#70drill bit (.028in. [1.17

mrn]) for cleaning being careful not to

enlarge hole. These are restricted flow

fittings.

If

holes are enlarged, valve deck

will receive excess oil. If holes are plug-

ged, valve train will run dry and wear out.

Note 2

-

Use a

#56

drill bit for cleaning

being careful not to enlarge hole. It is

critical that fittings be kept open.

If

restriction is plugged, injection pump

tappet, bottom, and plunger will wear

out.

FIGURE

38.

CLEANING ROCKER

BOX

OIL LINE AND RESTRICTION ORIFICES

37

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...