OIL LINES

At overhaul time the rocker box oil line should be

flushed with fuel, and a fine wire used to clean the

small holes, Figure

38.

Clean standpipe breather on

four cylinder engines.

Clean out all other oil lines and drillings with com-

pressed air whenever the engine is disassembled or

overhauled. Reach the oil gauge passsage by re-

moving the oil filter mounting plate.

External oil lines, the rocker box oil line, and the

internal oil line to the rear bearing are replaceable. If

damaged they should be replaced.

Restriction orifices are placed

in

the external oil lines

to regulate the quantity of oil delivered to the injec-

tion pump gearing and tappet and to the rocker arm

and valve train areas. Two orifices are located

in

the

Tee fitting at the injection pump, and one orifice is

located

in

the inlet fitting to each cylinder head.

0.028

inch size at heads (0.71 mm)

0.046 inch size at Tee (1.17 mm)

To

prevent injection pump

or

valve

train damage from lack of lubrlca-

tion, ensure that all restriction orifices are kept open.

Cleaning can be done using a fine wire or drill bit and

compressed air.

OIL FILTER (Full

Flow)

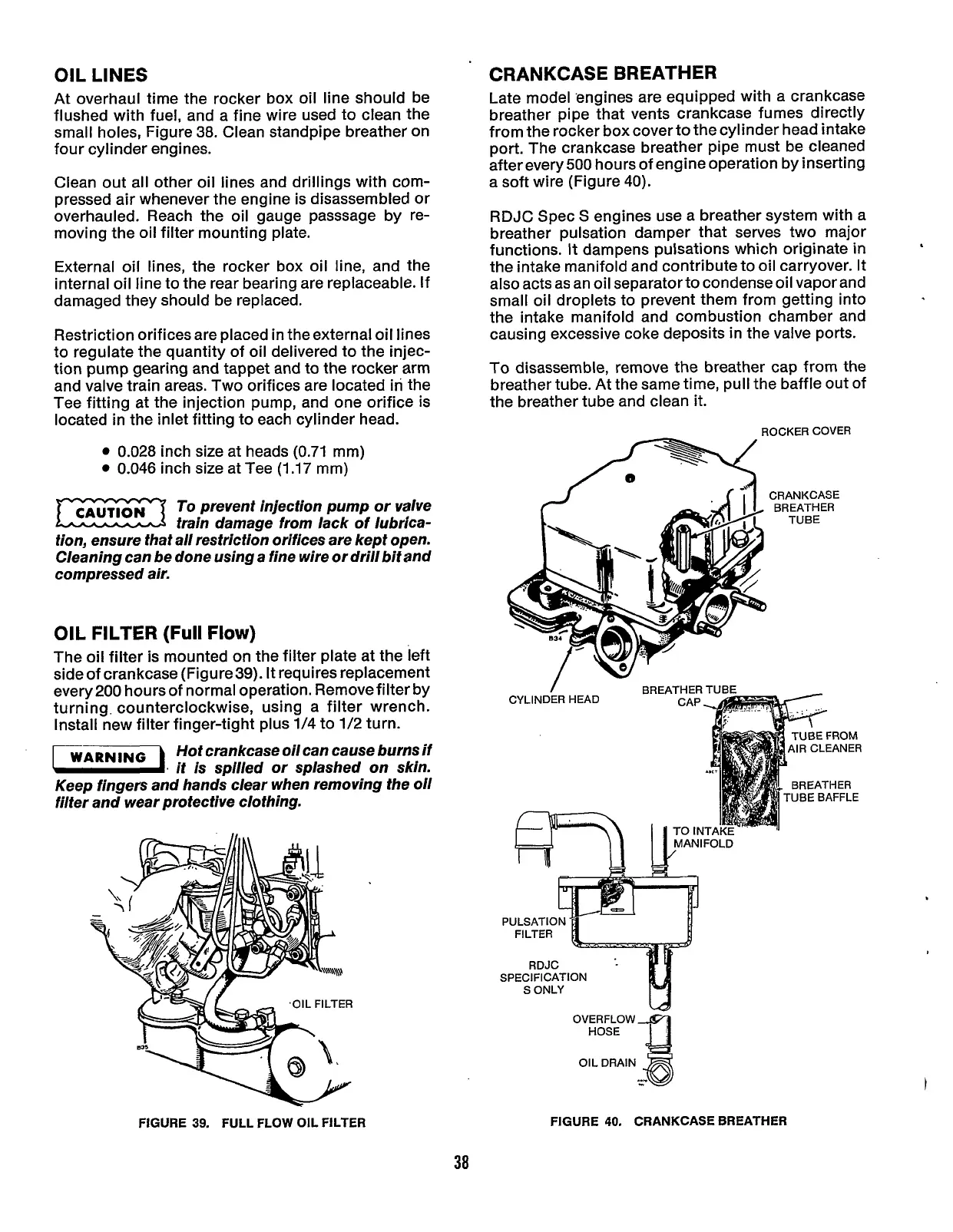

The oil filter is mounted on the filter plate at the left

side of crankcase (Figure39).

It

requires replacement

every200 hoursof normal operation. Remove filter by

turning. counterclockwise, using a filter wrench.

Install new filter finger-tight plus 1/4 to 1/2 turn.

rW=)

Hot crankcase oil can cause burns if

’

it is spilled

or

splashed on skin.

Keep fingers and hands clear when removing the

011

filter and wear protective clothing.

FIGURE

39.

FULL FLOW OIL FILTER

CRANKCASEBREATHER

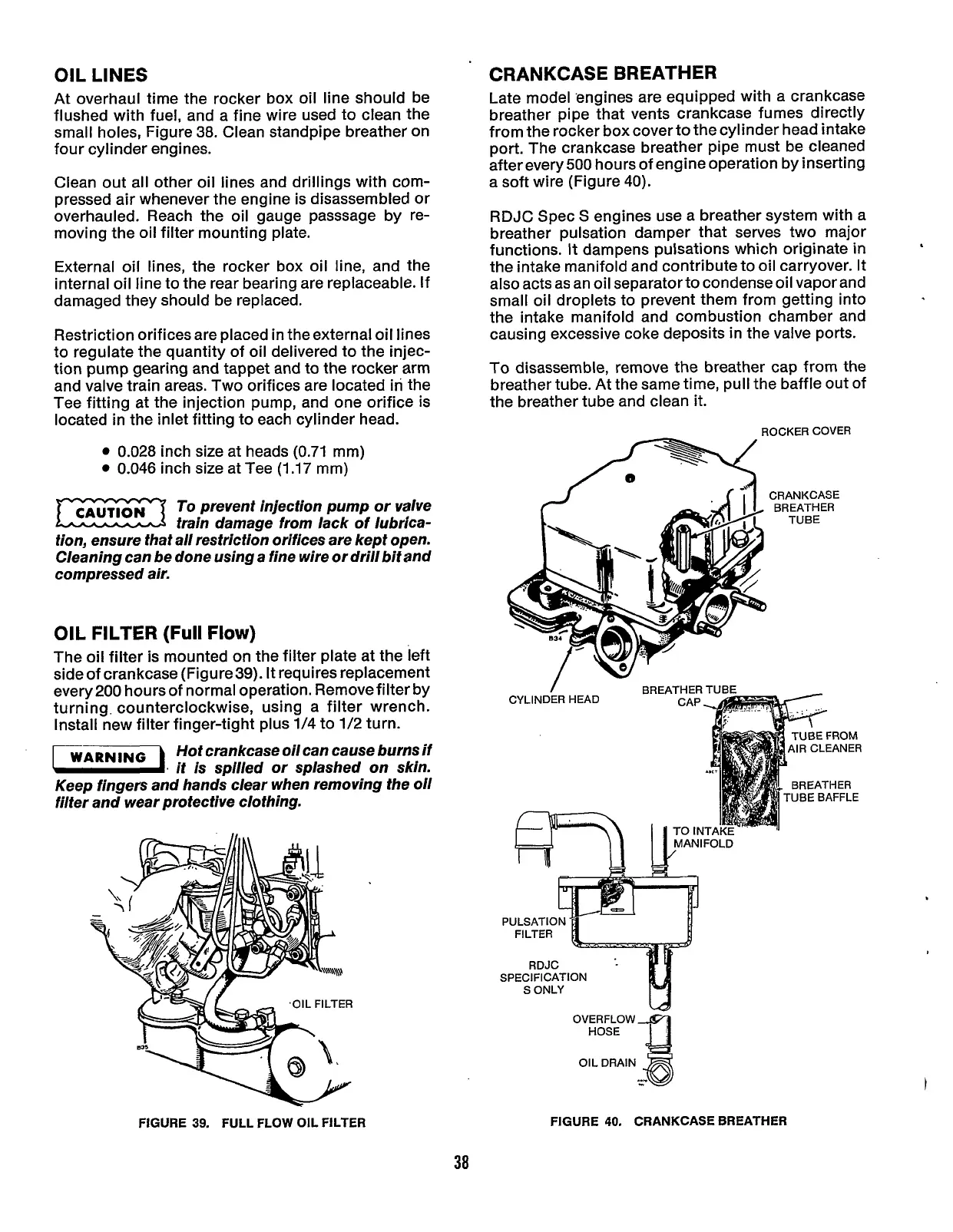

Late model ‘engines are equipped with a crankcase

breather pipe that vents crankcase fumes directly

from the rocker box coverto the cylinder head intake

port. The crankcase breather pipe must be cleaned

after every500 hours of engine operation by inserting

a soft wire (Figure 40).

RDJC Spec

S

engines use a breather system with a

breather pulsation damper that serves two major

functions.

It

dampens pulsations which originate

in

the intake manifold and contribute to oil carryover. It

also acts as an oil separator to condense oil vapor and

small oil droplets to prevent them from getting into

the intake manifold and combustion chamber and

causing excessive coke deposits in the valve ports.

To

disassemble, remove the breather cap from the

breather tube. At the same time, pull the baffle out of

the breather tube and clean

it.

ROCKER COVER

fi

M’/

/

BREATHER TUBE

CYLINDER HEAD

TUBE BAFFLE

FILTER

RDJC

SPECIFICATION

S

ONLY

OVERFLOW

OIL DRAIN

FIGURE

40.

CRANKCASE

BREATHER

38

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...