FR-N3X

1

6-1

6-2

6-3

6-4

6-6

6-7

LEADER

LEADER

LE8010

LP-8010-02

A-BEX

0J12

0F001

0J16

---

---

---

ADJUSTMENT PROCEDURES-1

MD ADJUSTMENT

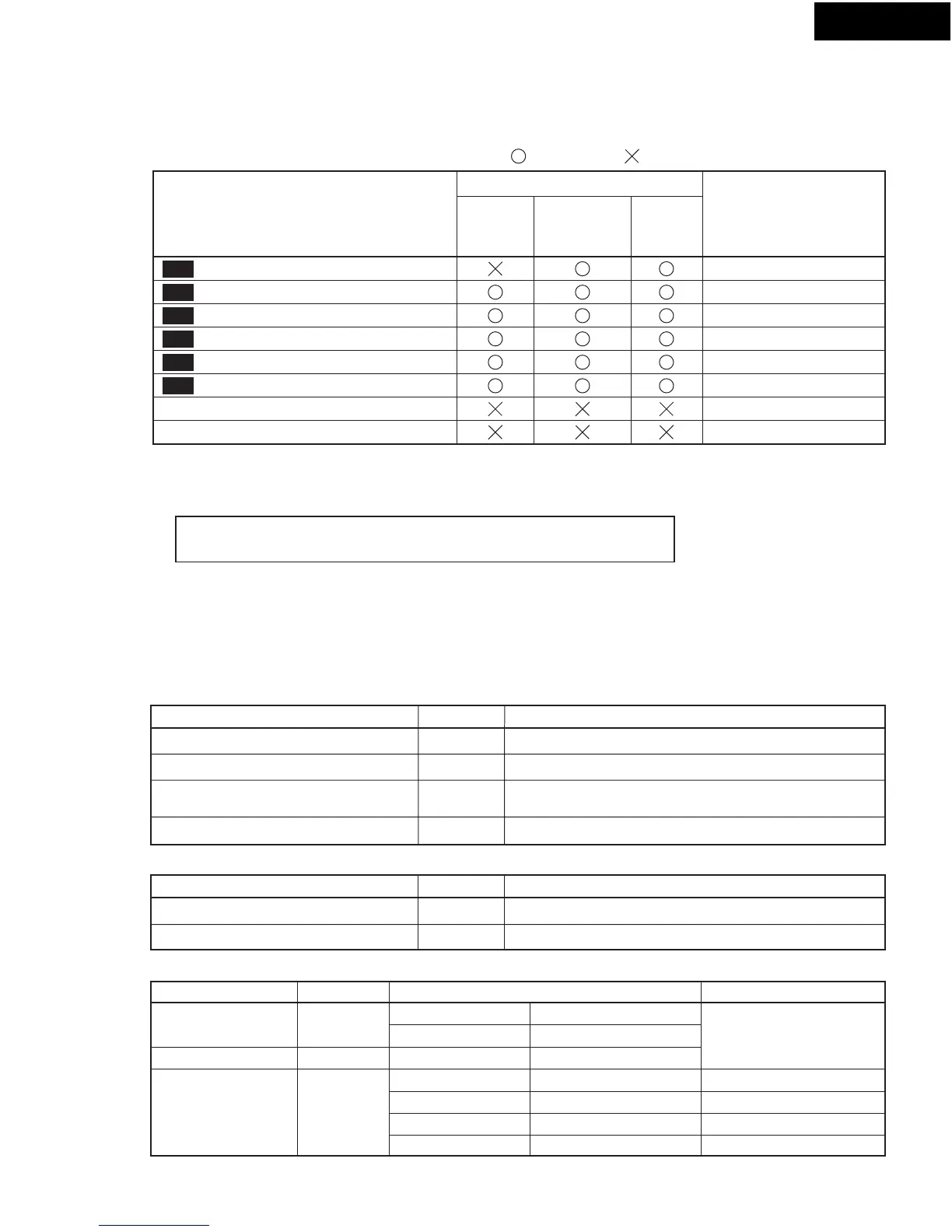

1.Necessity for adjustment

unnecessarynecessary

Exchanged parts

Pickup unit

Parts on MD

mount,

and Motors

Mechanical

parts

Adjustment of Temperature Compensation Offset

Adjustment of laser power

Check of laser power

Adjustment of Traverse (EF balance)

Check of error rate in high reflectance disk

Check of error rate in low reflectance disk

Adjustment of focus Bias

Check of focus bias

2. Notes in adjustment

2-1. Laser of optical pickup

2-2. Perform adjustment using test mode.

2-3. Perform adjustment as the indicated turn.

2-4. After adjustment should cancel test mode.

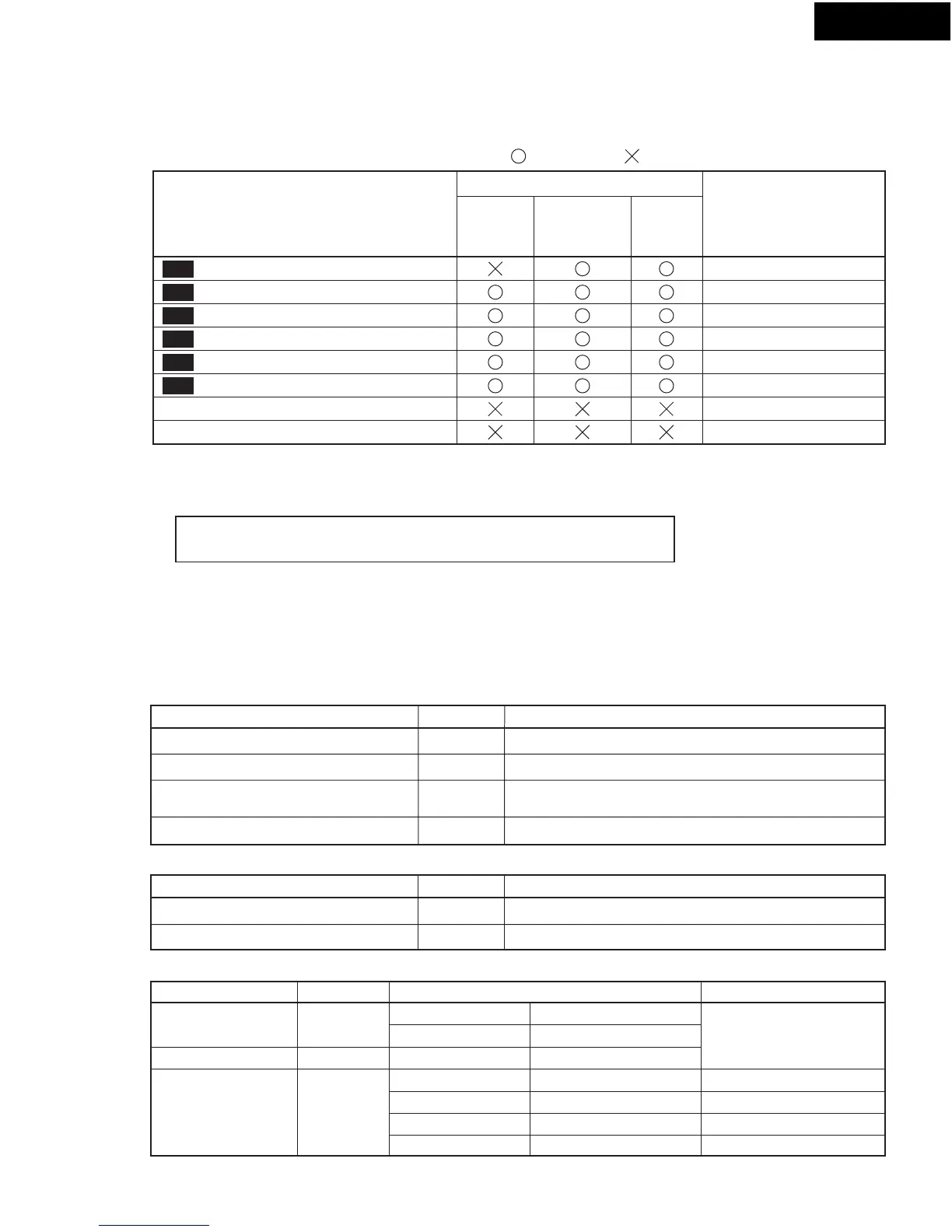

3. Equipment

Digital volt meter

Oscilloscope

Optical sensor

Laser power meter

Frequency range is 40MHz or more.

The calibration of the probe is performed.

In case adjust, don't look at the laser of the pickup unit.

You have fear of loss of eyesight.

Name

Name

Name

3-1. Measuring instruments

3-2. Test disks

Description and remarks

DetailsPart No.

Manufactured

Standard disk for recording/play back

FFC socket

PC board

Flexible flat cable

Extended JIG

1mm pitch, 7 cores

Part No. NCJIG-0J12

Part No. 25052307

---

Part No. NCJIG0J16

Part No. 25051759A

Part No. 25052313

Part No. 2045131012

Adjustment item

Manufactured

MO disk

High reflectance disk

3-3. JIGs

Description and remarks

Remarks

Black

Gray

PC board

FFC socket, 7 cores

FFC socket, 13 cores

Flexible flat cable (13cores)

TDM-381 Test disc

Extended JIG

Loading...

Loading...