32 33

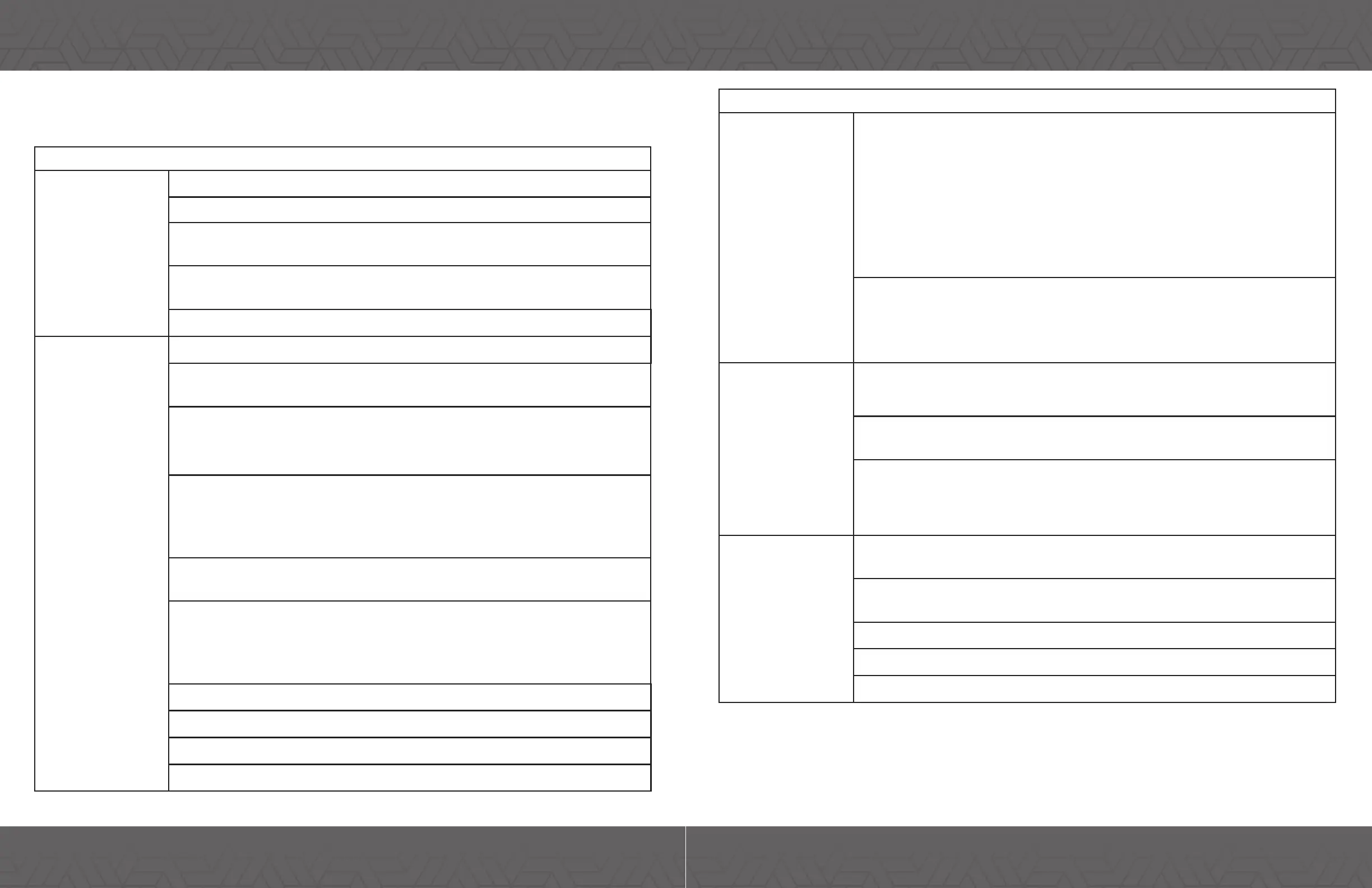

TROUBLESHOOTING GUIDE

Engine does not turn over

Engine turns over, but

does not start or run

Weak or dead battery

Ignition switch faultyNumerous other causes

Recharge or replace battery.

Check or replace switch.

Problem Reason Solution

Safety interlock switch (operator presence control)

not engaged

Check or replace safety interlock switch

(operator presence control).

Faulty safety interlock switch (operator presence

control)

Engage safety interlock switch (operator

presence control) prior to engaging starter.

Numerous other causes See engine manual or dealer.

Propane cylinder is empty Rell cylinder or replace with full cylinder.

Main fuel service valve on propane cylinder is

closed

REGO tting (fuel hose to cylinder connector)

is not fully seated

Manually open main fuel service valve on

propane cylinder.

Have certied dealer inspect regulator and

adjust or replace.

Manually close main fuel service valve. Dis-

connect REGO tting. Reconnect and hand

tighten to ensure secure connector is fully

seated. Slowly open main fuel service valve.

Propane cylinder OPD (overow protection

device) has been triggered.

Poor quality propane causes deposits of

particles in regulator or valves

Propane regulator out of adjustment or faulty

Manually close main fuel service valve.

Disconnect REGO tting. Wait 5 seconds.

Reconnect and hand tighten to ensure

secure connector is fully seated. Slowly

open main fuel service valve.

Have certied dealer inspect regulator

and clean or replace. Service engine valves

according to engine manual instructions.

Contact propane supplier to provide clean

HD5 propane.

Spark plug not ring

Faulty vacuum switch

Faulty oil pressure switch

Numerous other causes

Replace spark plug.

Check or replace vacuum switch.

Check or replace oil pressure switch.

See engine manual or dealer.

These troubleshooting steps are specic for propane fuel system issues. For other engine issues, refer to the

Engine Operator Manual and/or OEM Equipment Manual.

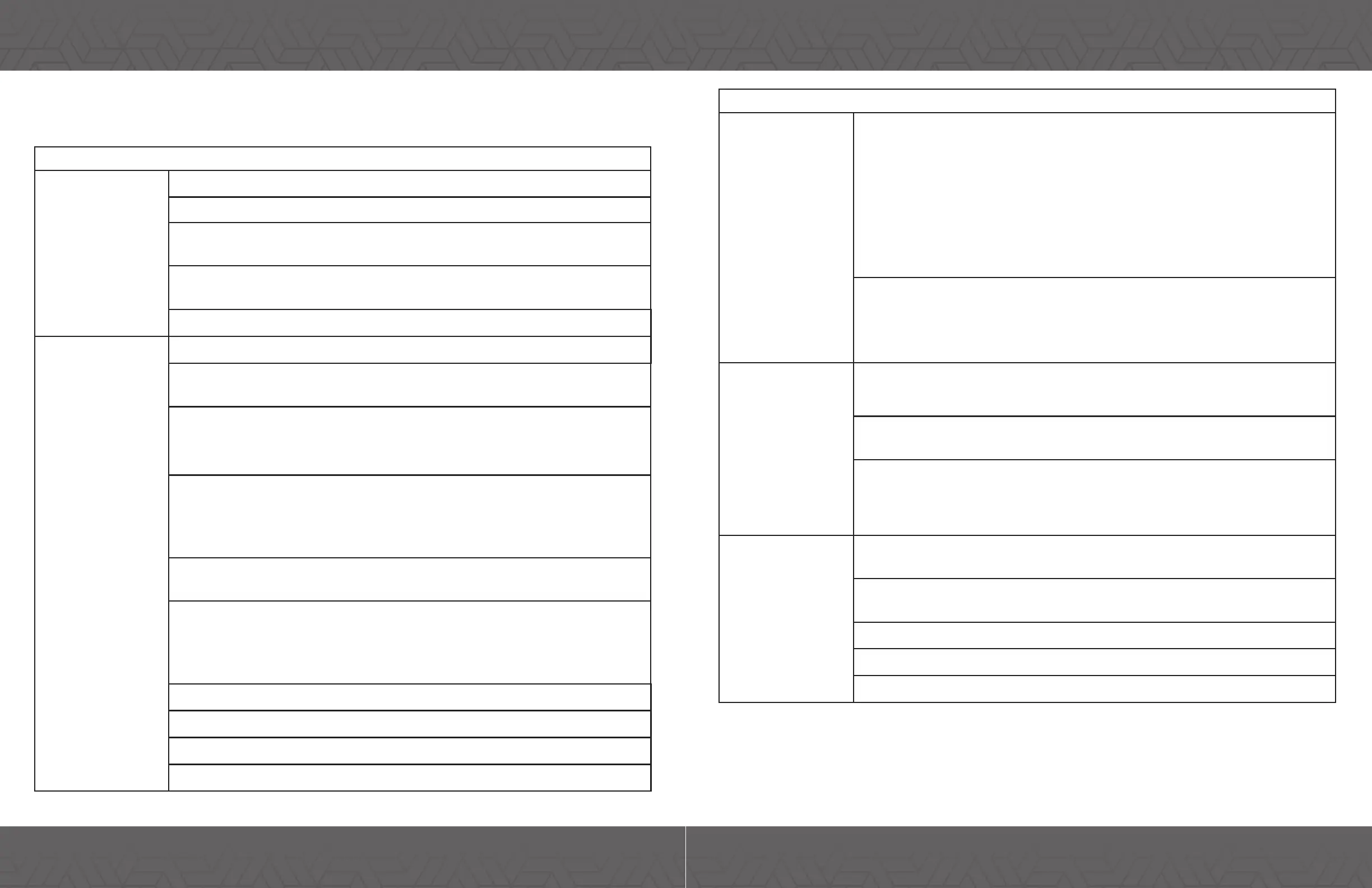

TROUBLESHOOTING GUIDE

Propane regulator freezes

and prevents ow of

propane

Propane cylinder forms

condensation or ice

Inconsistent or short

cylinder run time

Liquid propane is entering regulator

Low ambient temperature

Propane fuel is leaking

Propane consumption is abnormally high

Low ambient temperature

Propane cylinders not lled consistently

Propane regulator out of adjustment or faulty

• Ensure cylinder is designed for VAPOR

withdrawal and the correct orientation

(horizontal or vertical).

• Ensure cylinder is installed in correct ori-

entation. Make sure locator pin is inserted

into positioning slot on cylinder collar, and

follow orientation arrow indications/labels

on cylinder.

• Ensure propane cylinder is not overlled.

• Ensure use of application does not allow

operating angles to exceed equipment OEM

instructions.

It is normal condition for propane regula-

tor to operate at colder temperature than

ambient, which may cause condensation

or frost formation depending on ambient

temperature and humidity levels.

Close propane main fuel service valve.

Check fuel lines, REGO tting, and regulator

for any leaks.

Refer to section “Inconsistent or short cylin-

der run time” below.

Use cylinders that are properly and consis-

tently lled to the 80% maximum level.

Have certied dealer inspect regulator and

adjust.

It is normal condition for propane cylinder

to operate at colder temperature than am-

bient, which may cause condensation or ice

formation depending on ambient tempera-

ture and humidity levels.

Problem Reason Solution

Dirty air lter

Excessive engine load

Excessive engine RPM

Service air lter.

See engine manual or dealer.

See engine manual or dealer.

Loading...

Loading...