48 49

WARNING: When the Eective Operating Zone is small, fans must be used to force the mixing/

stirring of air and reduce high concentrations of CO.

TYPE OF WORK CONSIDERATIONS

WARNING: Proper ventilation must be combined with air mixing/stirring to reduce CO to a safe

level.

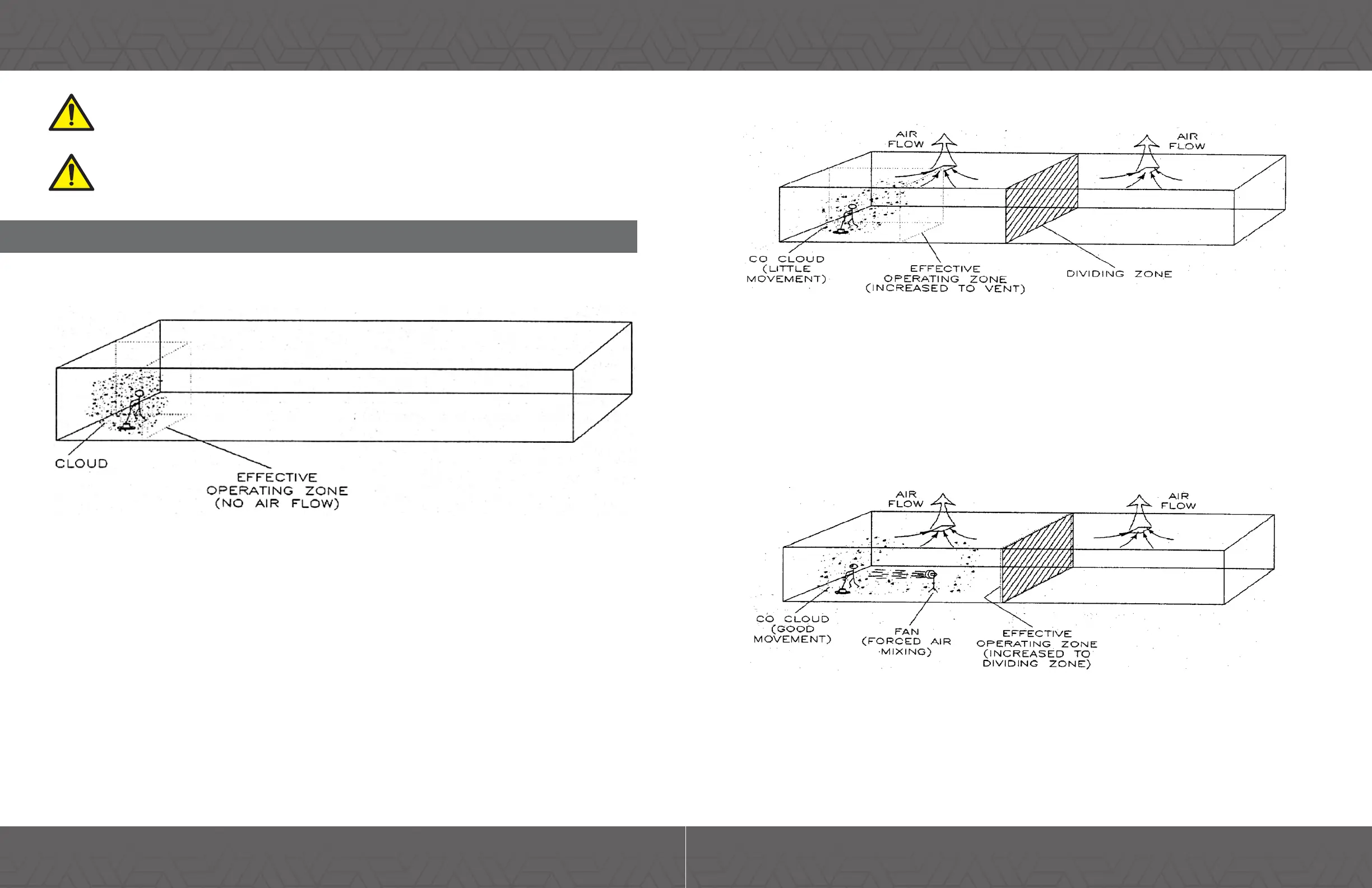

MODEL 1: Worst Case CO Management

EXAMPLES OF CO MANAGEMENT IN SPACES

Model 1 illustrates the worst case of CO management for several reasons:

• The room is not properly ventilated

• The air in the room is not mixed/stirred with any fans

• The type of work shown (stripping) requires low speed movement and results in a smaller “Eec-

tive Operating Zone”.

Note: Even though the room is large, due to these worst practices, the engine exhaust is concentrated near

the operator, resulting in high CO exposure.

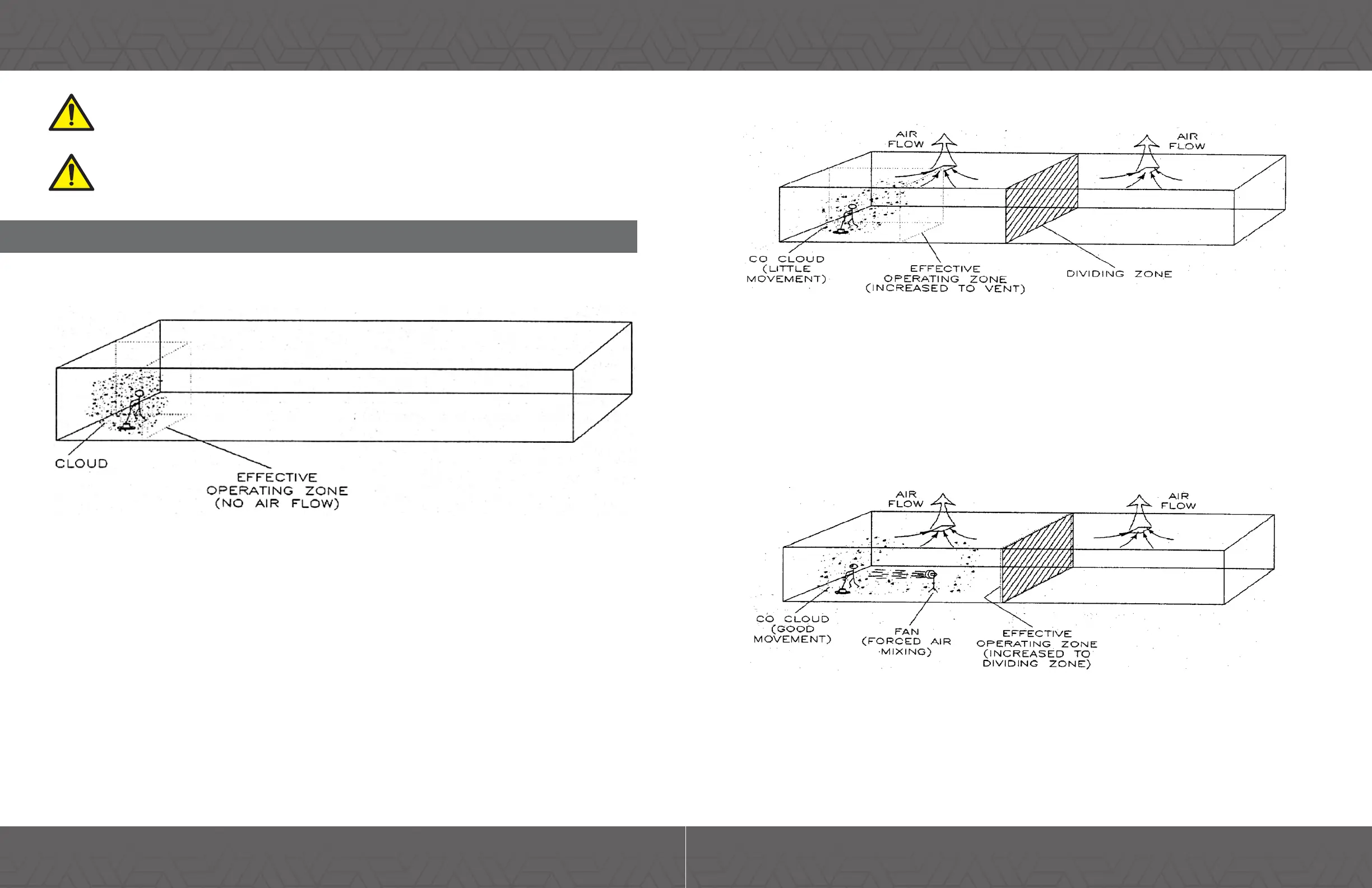

MODEL 2: Poor CO Management

EXAMPLES OF CO MANAGEMENT IN SPACES

Model 2 illustrates a slightly improved case of CO management, compared with Model 1, because air venti-

lation is introduced. As a result, the Eective Operating Zone is slightly increased and slightly lower levels

of CO concentration would be expected. However, because air is not mixed/stirred, and because the type

of work shown (stripping) requires low speed movement, there is still a potential risk of high CO exposure.

The CO cloud is still concentrated in a small area. Note the “Dividing Zone” shown above, this is the line

where airow changes direction. Because all of the CO exists on one side of the dividing zone, only half of

the room’s ventilation is eectively evacuating CO.

MODEL 3: Better CO Management

Model 3 illustrates an even more improved case of CO management, compared with Model 2, because the

air is being mixed/stirred with fan(s). Notice the CO concentration and the Eective Operating Zone (Ex-

panded to the Dividing zone) due to the forced air mixing. The CO cloud is still concentrated on one side of

the Dividing zone. As in Model 2, because all of the CO exists on one side of the dividing zone, only half of

the room’s ventilation is eectively evacuating CO.

Loading...

Loading...