50 51

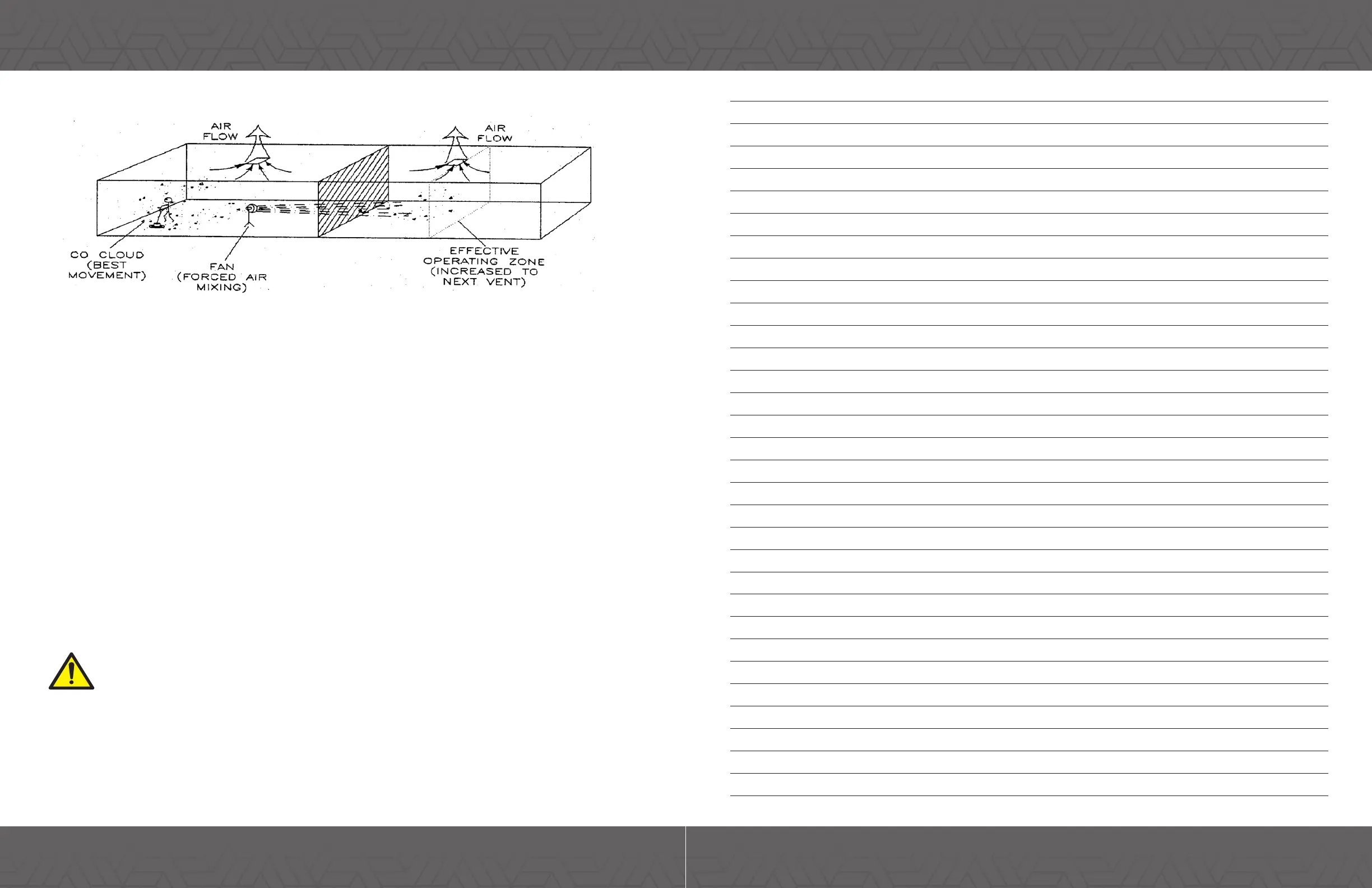

EXAMPLES OF CO MANAGEMENT IN SPACES

MODEL 4: Best CO Management

Model 4 illustrates the best case of CO management, because the forced mixing/stirring of air causes the

diusion of CO across the Dividing zones, and maximizes the Eective Operating Zone. This method max-

imizes the amount of diusion and maximizes the amount of CO that will be eectively evacuated by the

room’s ventilation, and thus minimizes the operator’s potential exposure to CO.

Maintenance of Equipment

There are several components and systems on the propane engine of this equipment that ensure minimal

CO output:

A three-way type catalytic converter to scrub CO, Hydro Carbons (HC), and Nitrous

Oxide (NOx) from the engine exhaust providing the lowest possible emissions.

Propane Fuel System: The regulator/carburetor of this engine (the fuel system) are specically calibrated

for the engine to run with a very “lean” air/fuel ratio which minimizes the production of carbon monoxide.

Air Cleaner: The engine is equipped with an air-cleaner that lters dust and contaminates from the air used

for combustion, resulting in a full and clean burn during engine ignition.

WARNING: The proper maintenance of equipment is vital to safe operation. LPG engines are

dependent on engine tune up, and air lter replacement. CO concentration (production)

skyrockets when the air to fuel ratio becomes fuel rich. Follow the recommended Maintenance

found in the Engine Operator Manual as well as in this Operator Manual.

NOTES

Loading...

Loading...