38 39

MAINTENANCE

WARNING: Remove the spark plug cap and read instructions before carrying out any cleaning,

replair, or maintenance operation. Wear proper clothing and working gloves whenever your

hands are at risk. Do not perform maintenance or repair operation without the necessary

tools and technical knowledge.

IMPORTANT: Never get rid of used oil, fuel or other pollutants in unauthorized places.

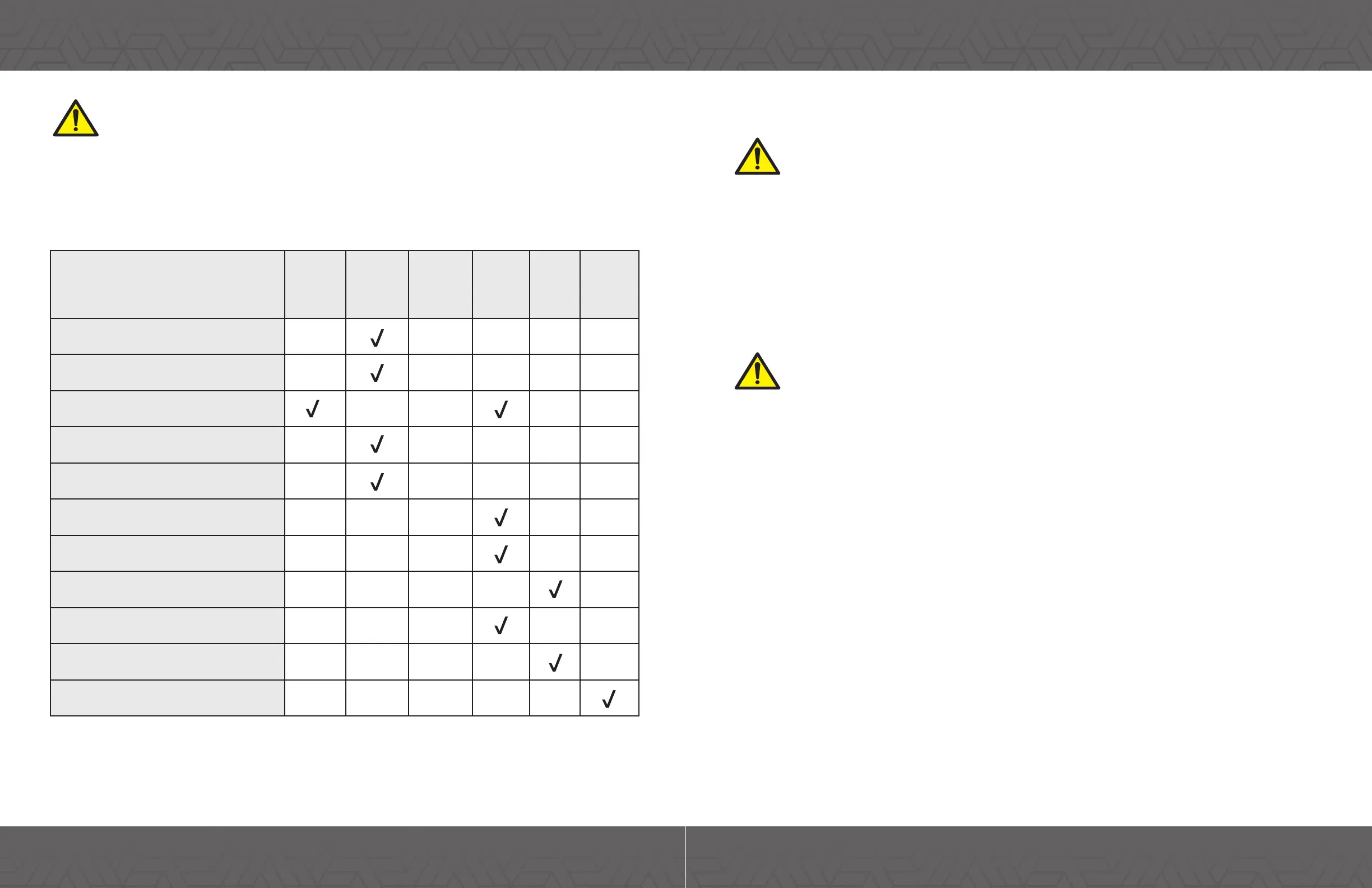

MAINTENANCE SCHEDULE:

Follow the hourly or calendar - whichever occurs rst - maintenance schedule shown in the following table.

Operation After

hours

hours or

Daily

hours or

every

season

Every

100

hours

Every

200

hours

Every

hours

Check oil level

Check or clean air

inlet screen

2

Change oil

1

Clean silencer

and engine

² and check

Check spark plug

Replace spark plug

3

Replace air cleaner

primary element

2

Replace air cleaner

secondary element

2

1

) Change oil every 25 hours if the engine is operating under heavy load or in hot weather.

2

) Clean air lter more frequently if the machine is operating in dusty areas.

3

) To be carried out by a specialized center.

MAINTENANCE

CHANGE OIL:

See sepcic chapter for the oil to be used.

WARNING: Drain oil while the engine is warm, being careful not to touch the hot engine nor

the drained oil.

a) Place the machine on a at surface.

b) Clean the area around the ller cap and unscrew the cap with dipstick.

c) Provide a suitable container for collecting the oil and unscrew the drain plug.

d) Ret the drain plug and fully tighten it having made sure that the gasket is in the right position.

e) Fill up with fresh oil.

f) Check that the oil level has reached the “MAX” notch on the dipstick.

g) Close the cap again and clean up any traces of oil that was possibly spilt.

NOTE: The oil capacity is about 2.0 Liter

WARNING: The length of time that propane can be left in your fuel tank and carburetor with

out causing functional problems will vary with such factors as propane blend, your storage

deterioration. Propane will oxidize and deteriorate in storage. Deteriorated propane will

cause hard starting, and it leaves gum deposits that clog the fuel system. As a result, if the

engine is not used for more than one month, the fuel oil shall be drained thoroughly to prevent

from deterioration of the fuel in the fuel system and carburetor. The failure of the fuel system

or engine performance arising from improper storage are beyond the scope of the warranty.

CLEAN SILENCER AND ENGINE:

Silencer must be cleaned when the engine is cold.

a) Use a jet of compressed air to remove any debris and dirt that could cause a re from the silencer and its

protective cover.

b) Make sure that the cooling air intakes are not blocked.

c) Clean the plastic components with a sponge soaked in water and detergent.

AIR FILTER MAINTENANCE:

a) Clean debris in the air lter cap and rain cover.

b) Open the clips on the two sides of air lter cover.

c) Gently shake element up and down, take out air cleaner primary element and secondary element.

d) Tap the cartridge on a solid surface and blow it from the inside with compressed air to remove dust and

debris.

IMPORTANT: Do not use water, petrol, detergents or any other products to clean the cartridge.

e) Clean the inside of the lter housing, making sure to block the inlet duct with a rag to prevent dust and

debris from entering the engine.

f) Remove the rag blocking the air inlet duct. Reinstall the primary and secondary air lter elements.

g) Reinstall the air lter cover and secure it to the lter housing with the holding clips.

Loading...

Loading...