152 Statistics

Sure Sort™ Operator Manual

OPEX Corporation

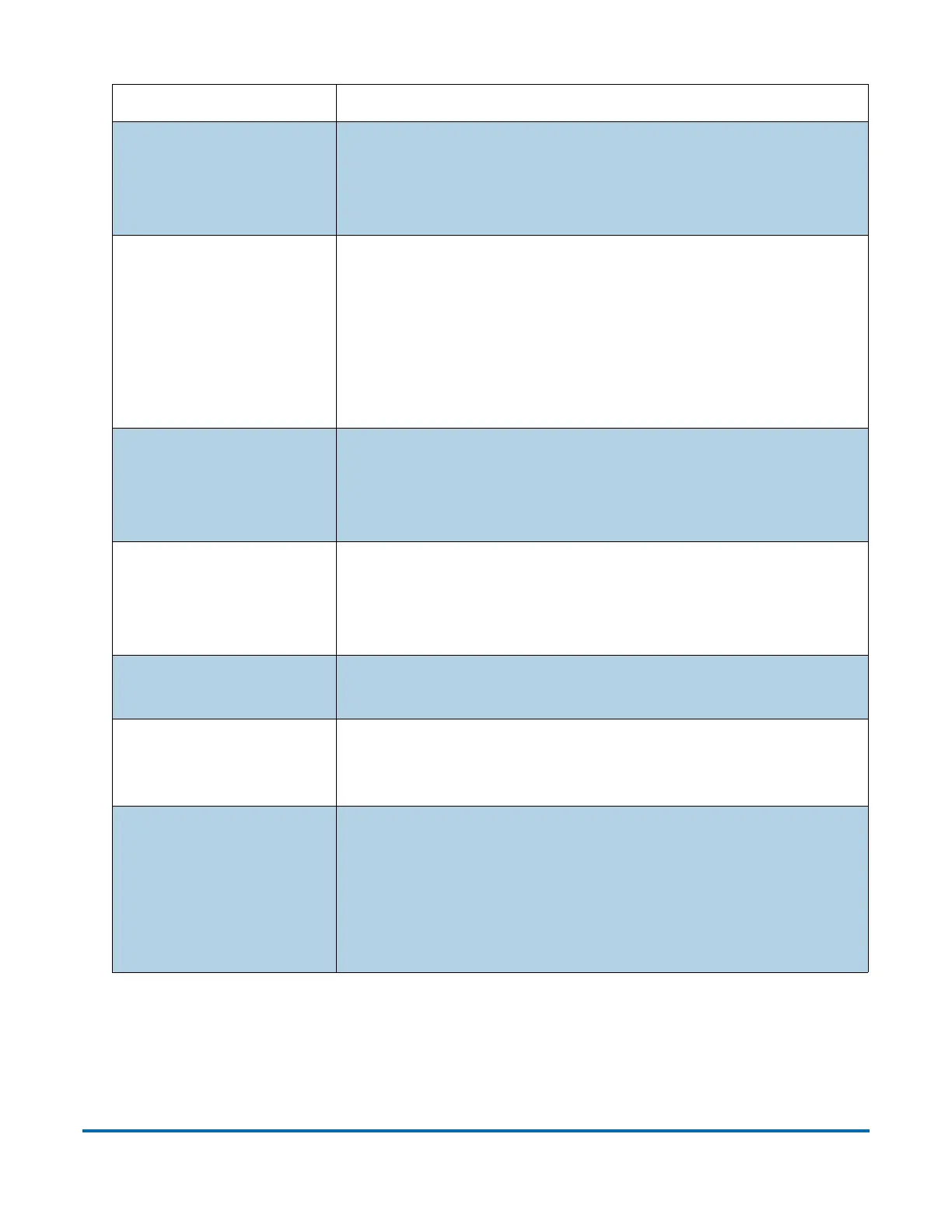

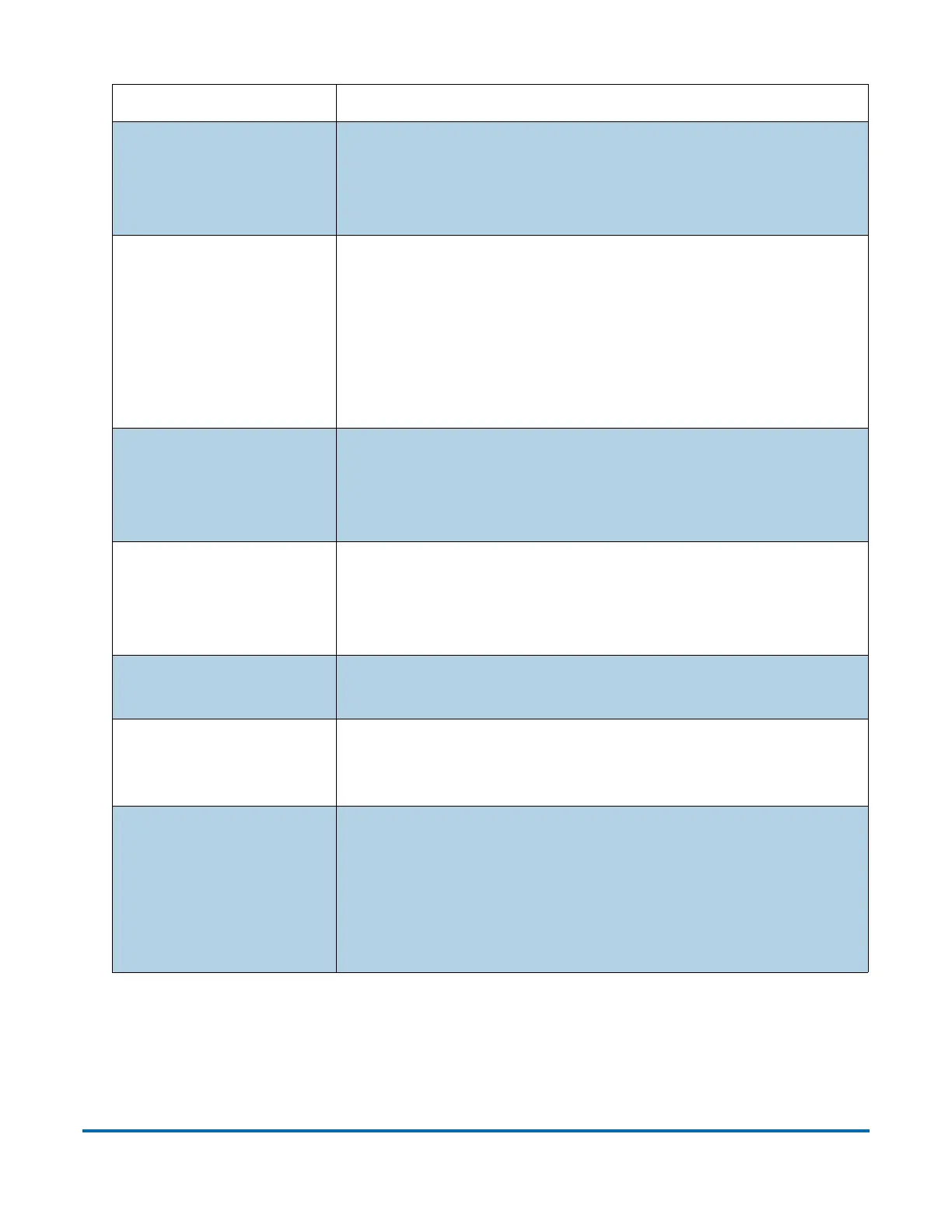

iBOT Conveyor Stall

Occurs when an iBOT cannot detect any movement in

its conveyor, if the conveyor is being prevented from

moving at its desired speed, or if the conveyor is

spinning without having a loaded product.

iBOT Missed Index

There is an index mark located in the loading column,

just below the loading position, as indicated by the

arrow in the picture. iBOTs recognize this mark and

use it to synchronize their position every time they go

through the loading column. If an iBOT goes past the

position where it expects to see the index mark, but

does not see it, it signals this jam.

iBOT Not Above

Index

Occurs when an iBOT has either not passed above

the index mark or the Real-Time Controller has not

received confirmation that the iBOT has passed

above the index mark in the expected time.

iBOT Out of Control

Detected

Occurs when an iBOT has reached the out of control

speed limit despite attempting to control it. In these

cases, the iBOT’s parking brake is utilized to control

the speed.

iBOT Over-Voltage

Detected

Occurs when an iBOT detects that it has charged up

to a voltage that exceeds its maximum limit.

iBOT Reset

Detected

occurs when the Real-Time Controller detects that an

iBOT has reset itself. This can be due to an

unexpected power cycling of the iBOT.

iBOT Stall Jam

Occurs when an iBOT does not move the expected

minimum distance over a set period of time. This can

be due to something impeding the iBOT’s forward

progress, something caught in the iBOT’s axle, an

overweight item being placed onto the iBOT, or

something dragging on the back of the iBOT.

Jam message Description

Loading...

Loading...