Faults

- 23 -

optek-Manual--1004-2006-02--TF16-US-2011-06-20

www.optek.com

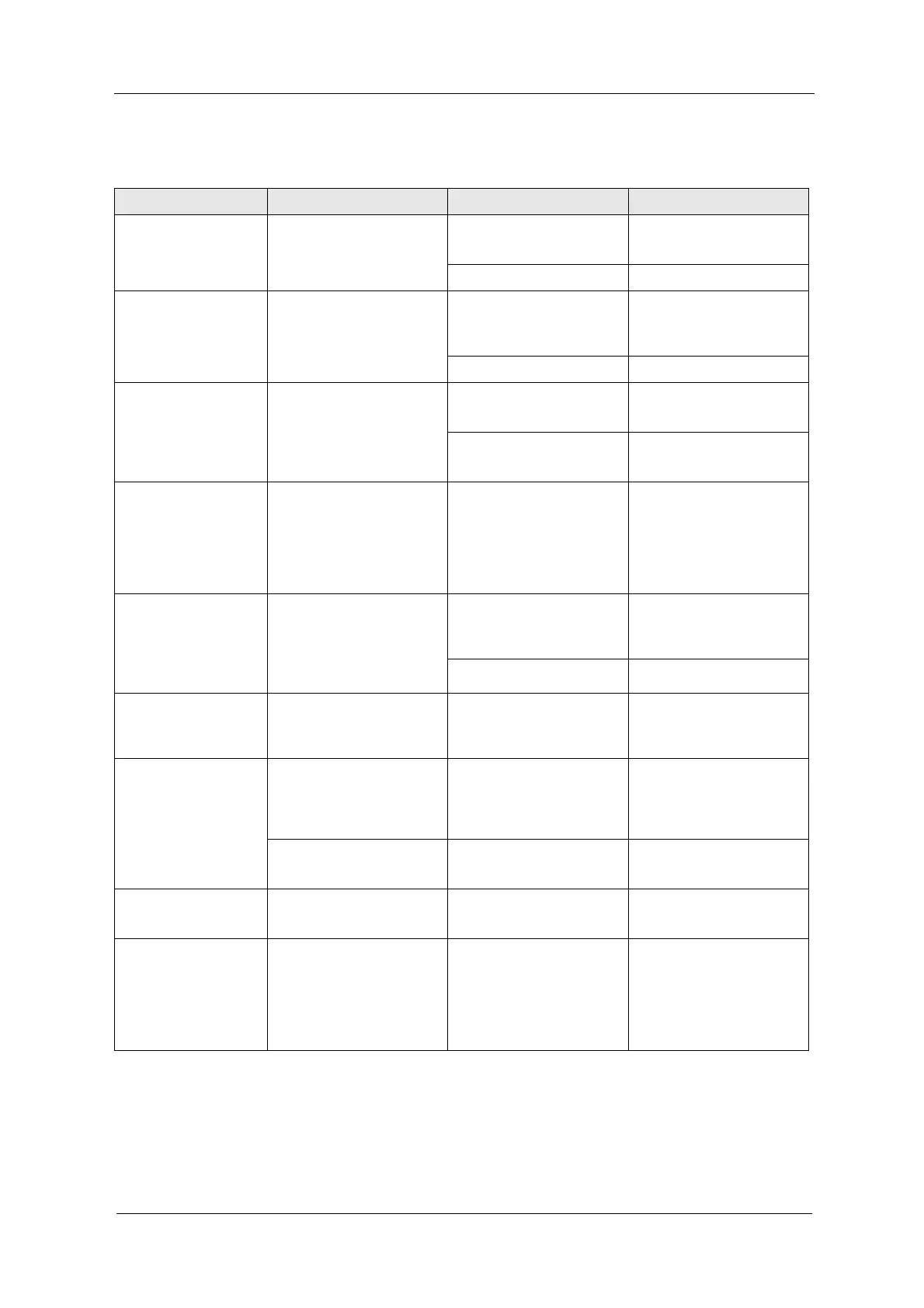

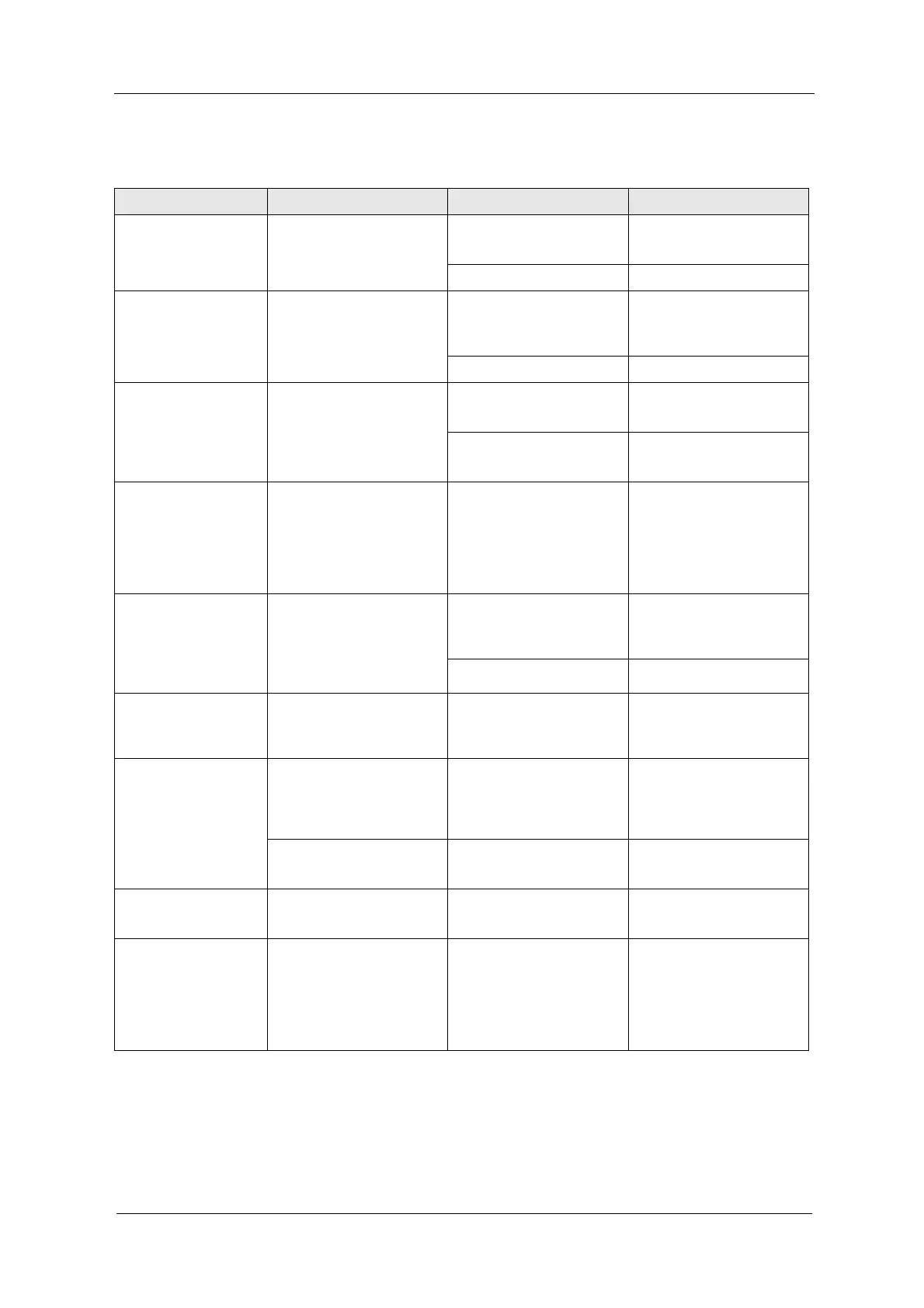

Tab. 10 Possible faults and remedies

Possible fault Possible remarks Cause Remedy

Failure of

lamp module

• "Lamp failure" LED of conver-

ter flashes.

• Signal loss

Lamp cable between sensor

and converter defective

• Continuity test of lamp cable

• Exchange lamp cable for new

one.

Lamp module defective • Exchange lamp module.

Detector failure -

Detector cable between sen-

sor and converter defective

• Continuity test of detector

cable

• Exchange detector cable for

new one.

Detector defective • Exchange detector.

Condensate formation

Unrealistic, random measuring

results

Humidity gets into optical

housing and forms condensa-

tion deposits on windows.

• Use airpurge,

chapter 6.3.

O-Ring missing or defective

• Disassemble sensor assem-

blies and check O-Rings,

exchange if necessary.

Wrong results

• Results are fluctuating.

• Zero point is drifting.

• Sensor body windows are

dirty.

• Sensor body windows are

corroded.

• Lamp module near failure,

lamp module near the end of

its life.

• Clean sensor body window.

• Exchange sensor body win-

dow for sapphire window.

• Exchange lamp module.

Connection error

• No function

• No "Lamp failure" LED mes-

sage

Detector cable between sen-

sor and converter defective

• Continuity test of detector

cable

• Exchange detector cable for

new one.

Sensor cable incorrectly con-

nected to converter

• Check and revise connec-

tions.

Measuring range excee-

ded

↑ − ↑ − ↑

Converter indicates flashing

Process conditions

• Amplify measuring range.

• If the measuring range cannot

be amplified, apply absorption

measurement.

mA-signal (output)

mA-output delivers correct cur-

rent results if measuring results

are low

and too low current results if

measuring results are high.

Connected load > 600 ohms

• Check resistance of wiring.

• Use appropriate mA-input.

Small deviations given in %

Poor calibration of the receiving

mA-input

• Compensation by adjusting

calibration of the sending mA-

output.

mA-signal (input) Small deviations given in %

Poor calibration of the sending

mA-output

• Compensation by adjusting

calibration of the receiving

mA-input.

Defect of converter

None of the above mentioned

errors can be detected.

-

• Send system (converter and

sensor) to optek for checking

purposes. If necessary, the

sensor body can remain in

the pipeline so that only the

optical arms and the conver-

ter have to be sent.

Loading...

Loading...