Service Manual

Manufactured by Bersch & Fratscher GmbH

10

version 10/2008

OPTIMA 2100

13. Disposal

The high pressure spray gun is not subject to special disposal regulations.

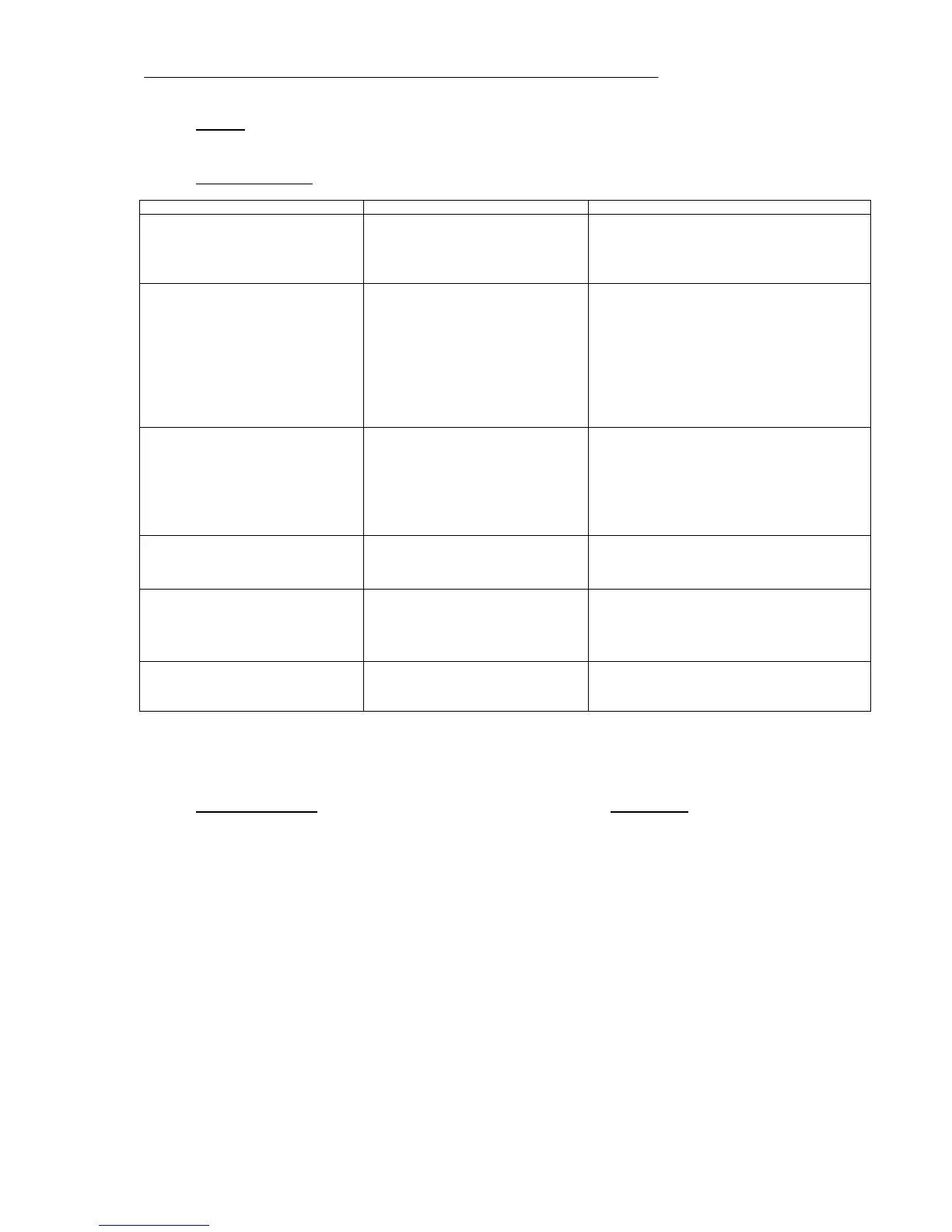

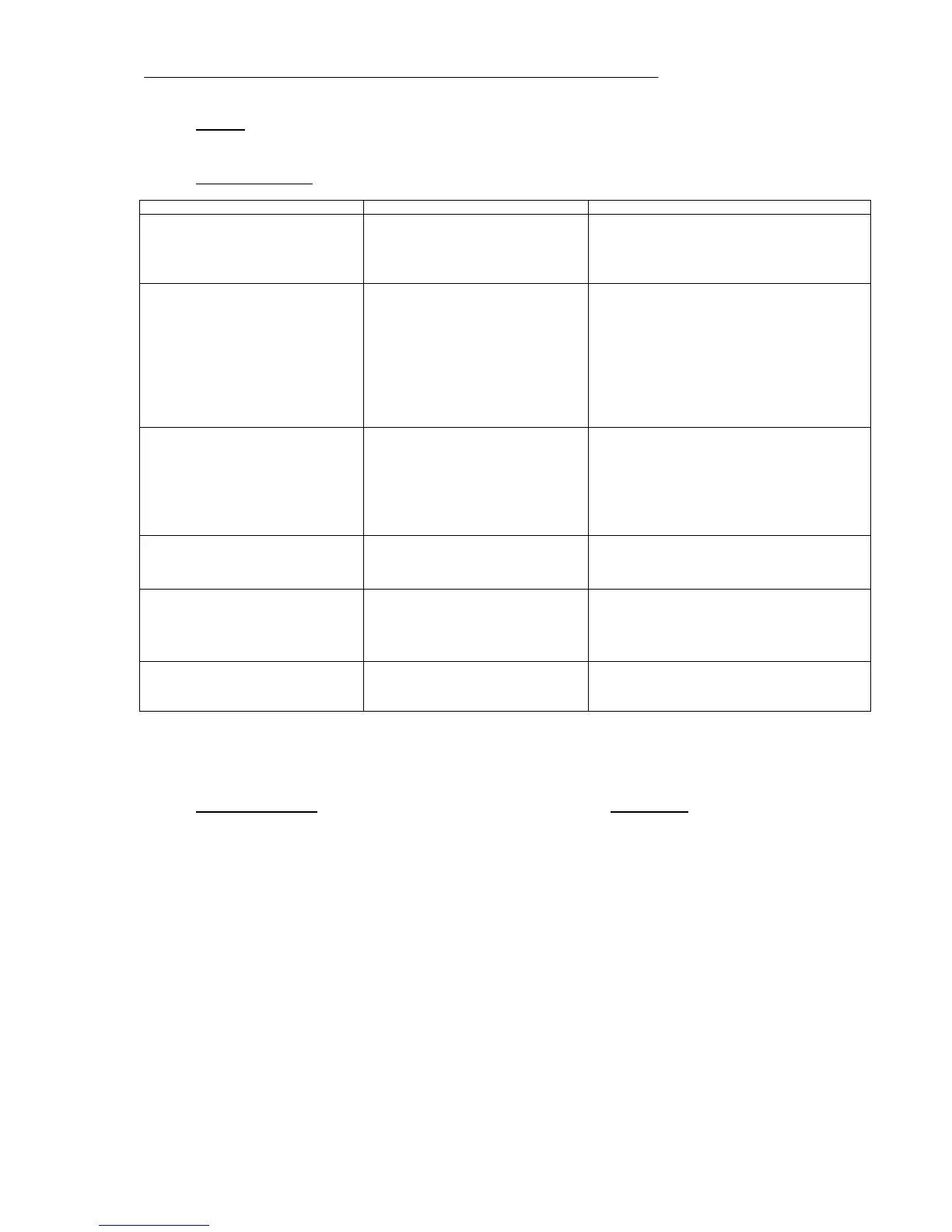

14. Trouble possiblilities

Functional disturbance Possible cause Repair

14.1. Decrease in paint flow

when spraying:

* Filter of gun clogged.

* Viscosity too high.

* Too low material pressure.

Clean the filter ( see point 9.3. )

Water down the paint.

Increase air inlet pressure of the pump.

14.2. Irregular jet:

* Airless nozzle clogged.

* Filter of gun clogged.

* Nozzle to wide or worn out.

* Viscosity to high.

* No, or not enough atomizer air.

* Air slits dirty.

* Atomizer air pressure to high or too low.

Replace nozzle ( see point. 10.4. )

Clean the filter ( see point 9.3. ) or change the filter.

Insert new nozzle ( see point 10.4. )

Water down the paint.

Open regulation no. 1248 – U6 ( see point 8.4)

Clean with a brush. Do not u use a wire brush!

Adjust pressure regulation valve.

14.3. Spray gun still sprays

when closing:

* Seal washer or needle ball worn out.

* Needle spring has lost stress.

* Needle seal too strong thus needle can

not be moved through the spring.

* Needle and needle sealing dirty.

Change parts ( see point 10.1 to 10.5. )

Replace spring ( see point 10.1. )

Change sealings ( see point 10.2 )

14.4. Spray gun leaks paint

on needle seal:

* Needle seal worn.

* Packing gland is not installed

tight enough.

Replace sealings ( see point 10.2. )

Tighten packing gland.

14.5. Spray gun is blowing:

* Valve spring fatigue.

* Valve sealing worn.

* Valve defective.

Replace spring no.1136 -20

Change valve sealing ( see point 10.3. )

Change valve.

14.6. Spray gun has no or to little

pre-air:

* Pre-air stroke screw not properly

adjusted.

Adjust pre-air ( see point 8.10. )

Regularly cleansing and servicing prolongs the life-span of the high pressure spray

gun. For a general cleansing we offer a professional service in our company.

15. Available accessories

Order number

Insert filter 50 µm / 295 msh red colour 001233-74

100 µm / 150 msh yellow colour 001233-75

150 µm / 80 msh white colour 001233-76

Nozzle carrier complete with nozzle bores in diameters 01248-U8

0,18 ; 0,23 ; 0,28 ; 0,33 ; 0,38 ; 0,43 mm

(and further sizes in different spraying angles

are also on stock available,

deviating nozzle bores on request.

Nozzle cleaning needles 000345-44

AirCombi hose pair 7,5 meter , G1/4“air connection

NPS1/4“ material connection 2462-U1

AirCombi soft hose pair 7,5 meter , G1/4“air connection

NPS1/4“ material connection 2462-U2

Repair kit 000345-172

Air hose Pk 6 endless 003633.05

(cut to length on request and on both sides G ¼ “union nut).

Loading...

Loading...