Service Manual

Manufactured by Bersch & Fratscher GmbH

11

version 10/2008

OPTIMA 2100

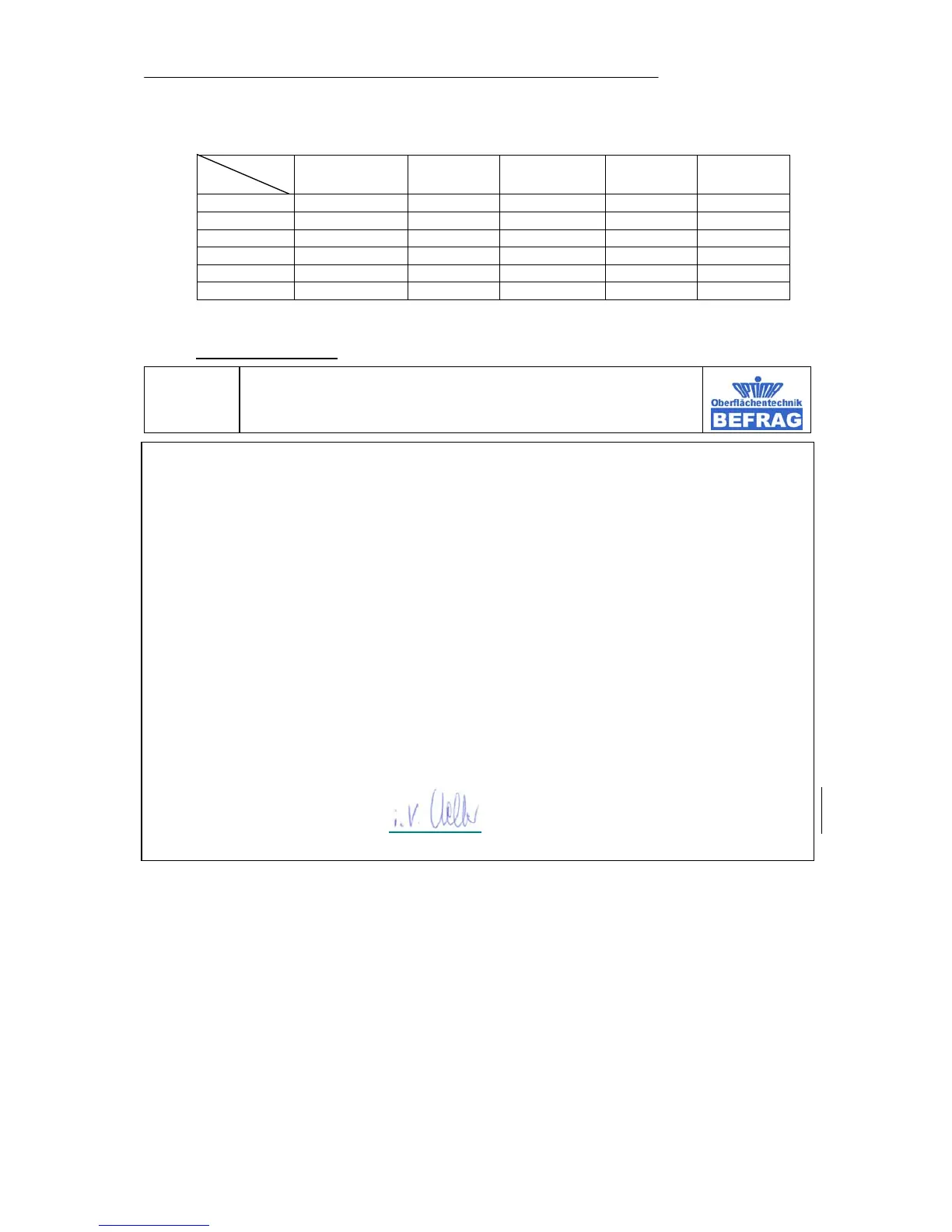

Current nozzle sizes:

Spray angle

Orifice size

20 ° 30 ° 40 ° 50 ° 60 °

0,18 mm 218 318 418 - -

0,23 mm 223 323 423 523 623

0,28 mm 228 328 428 528 628

0,33 mm 233 333 433 533 633

0,38 mm 238 338 438 538 638

0,43 mm 243 343 443 543 643

Other sizes available upon request.

16. Declaration of conformity

CE 08

DECLARATION OF CONFORMITY

according to the EC-Guide-Line Machines

We, manufacturer

BEFRAG

Bersch & Fratscher GmbH

Spezialfabrik für Lackiertechnik

63791 Karlstein

declare under our sole responsibility that the product

HIGH PRESSURE Spray Gun AIR COMBI OPTIMA 2100 ( 250 bar ) no. 001248

• Conform with the relevant regulations of the EC-machine guideline (98/37/EG), including their changes at this time period.

• Conform with further relevant regulations of the EC-machine guideline including their changes at this time period.

Î Directive 94/9/EC – Equipment in explosion endangered environments. Use in zone 1; equipment of category 2

•

following harmonized standards ( or parts from this ) were used.

Î DIN EN ISO 12100, 2004-04 Part 1 and 2: Safety of machines.

Î EN 349 Minimum distances to avoid stem presses.

Î EN 23741 Noise formation

Î EN 457 Noise protection regulations.

• Î pr EN 349 Engineering safety regulations.

• Î pr EN 1953, 1998-12 Spraying apparatus for coating materials – Safety requirements.

Î DIN EN 13463-1 Non electric devices for using in explosion endangered areas.

• following national technical standards and specifications were used.

Î pr EN 614-1 Ergonomic formation basic principles.

Karlstein, date 01.10. 2008 (Mr. Bernward Keller, head of department spraying machines)

Loading...

Loading...