Service Manual

Manufactured by Bersch & Fratscher GmbH

7

version 10/2008

OPTIMA 2100

8.5 Trigger forces

Trigger pressure adaptation according to the material pressure.

- The spring force is adjustable from approx. 80 - 250 bar ( 1.138 - 3.557 PSI ).

- 250 bar tighten screw 1236-5 completely.

- 80 bar -unscrew screw 1236-5 to tappet.

-

For pressures in between 80 and 250 bar choose a correspondingly intermediate adjustment of the screw 1236-5

8.6 Round jet regulation

By means of the round jet regulation 1240-U5 atomization air is added to the flat jet cap from the sides.

Clockwise rotation little air - little adjustment to round jet.

Counter clockwise rotation much air - high adjustment to round jet.

8.7 Adjustment of atomization air cap

a.) Put pump pressure at 0 , release trigger 1248-U4 completely - pressure of hose relieves.

b.) Secure spray gun by a 90 ° clockwise rotation of the safety lever 1237-3.

c.) Release lock nut 1248-4 by hand.

d.) Put atomization cap 1248-U2 into required position.

e.) Tighten lock nut 1248-4 well by hand.

(see illustration 1)

8.8 Painting distance and spray gun guidance

8.8.1 Adjustment of atomization air cap

The position of the atomization air cap and the spraying nozzle determines the direction of the spray jet.

Turn the atomisation cap according to the desired spray direction (the spraying nozzle turns with it)

Illustration 2: Air cap adjustment

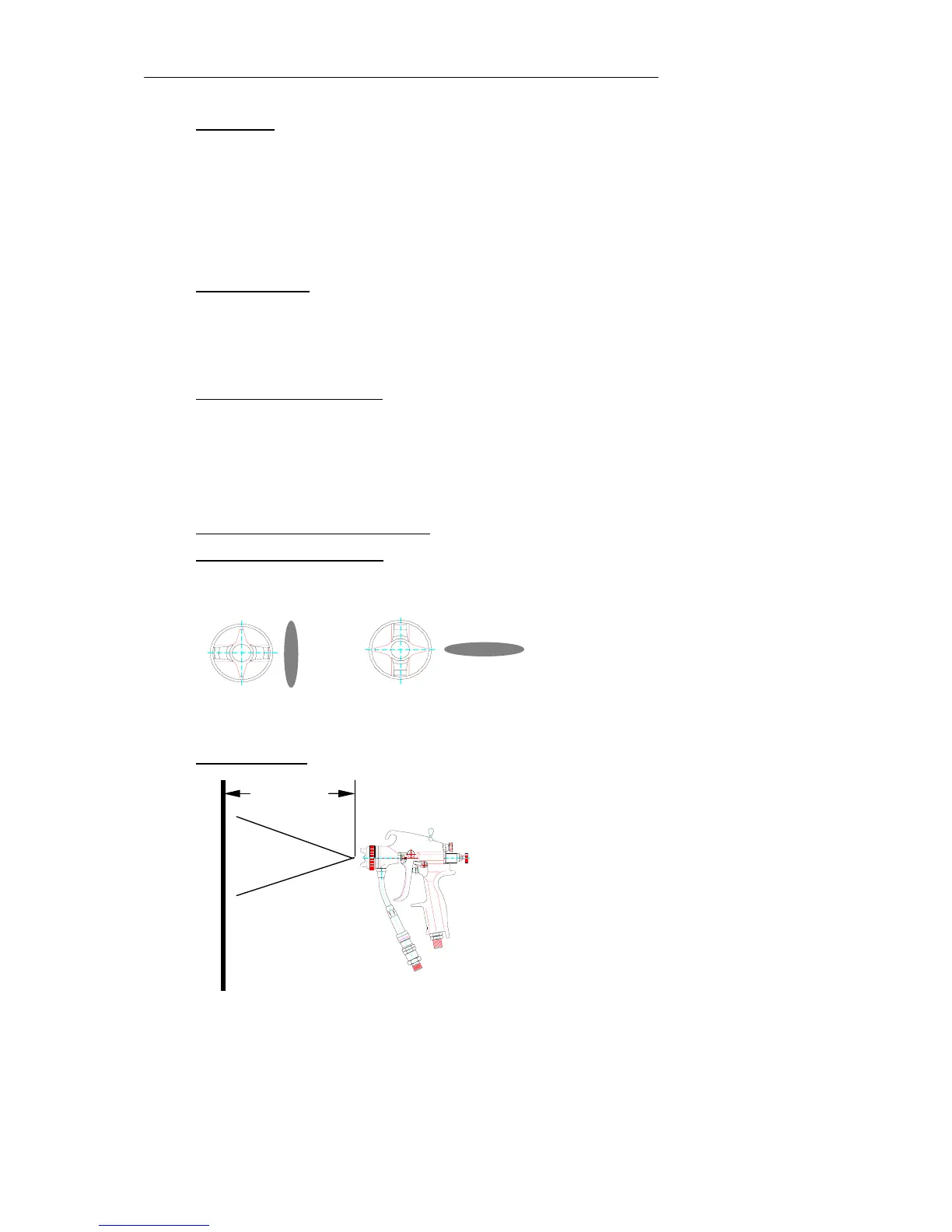

8.8.2 Spray gun guidance

OPTIMA 2100

Illustration 3: Spray gun guidance

The paint spray gun must always be held at a 90° angle to the painting surface.

25-30 cm

Loading...

Loading...