Service Manual

Manufactured by Bersch & Fratscher GmbH

6

version 10/2008

OPTIMA 2100

6. Description of function

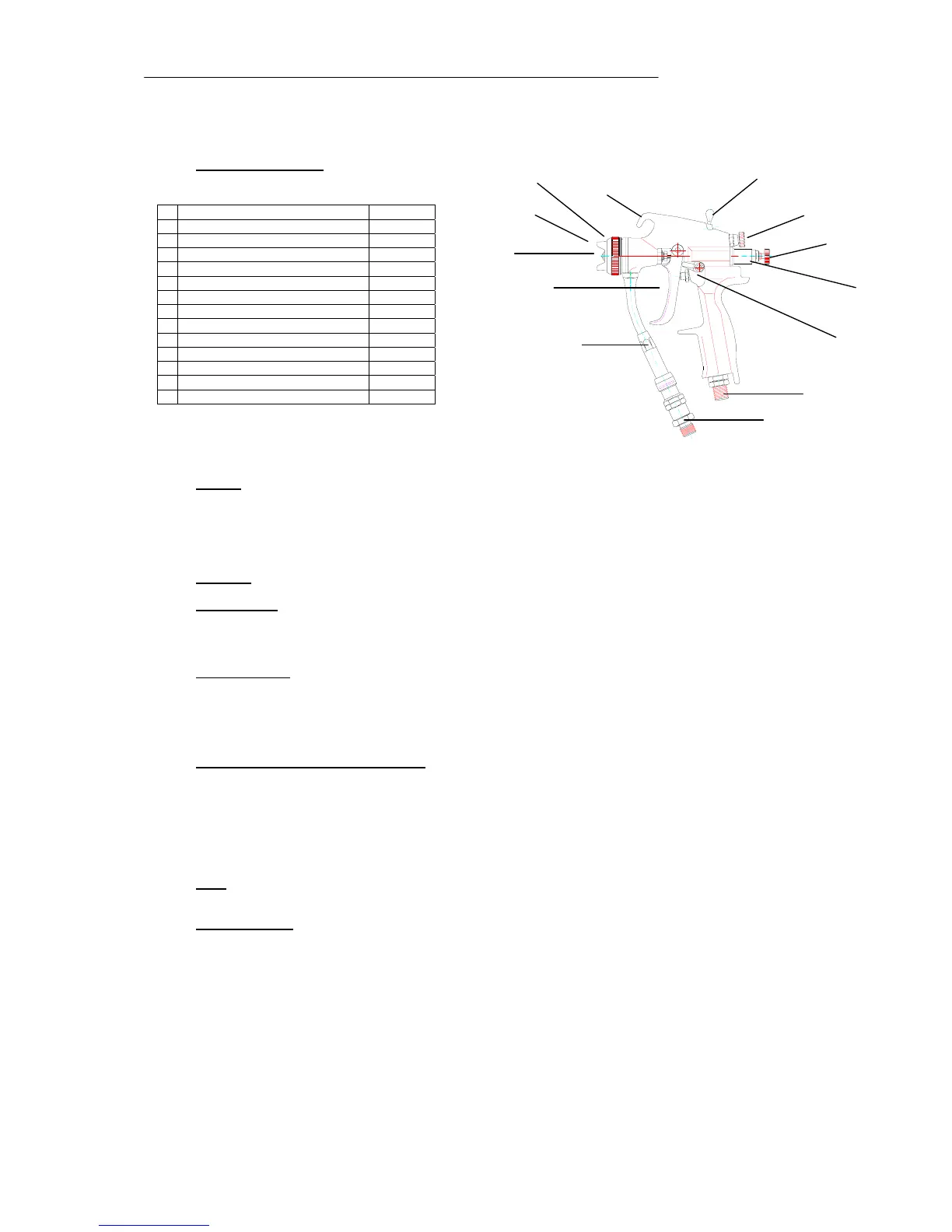

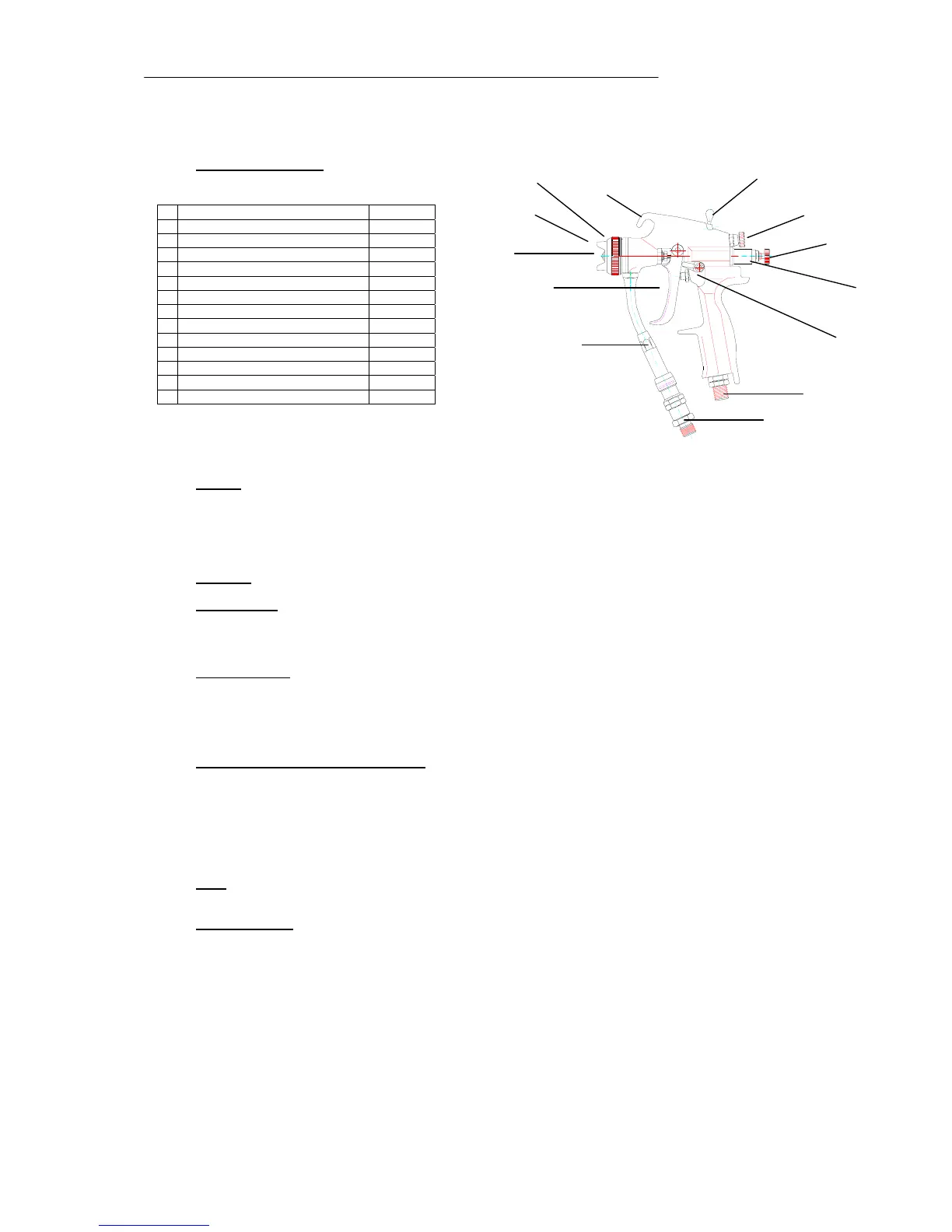

Description Order no.

A Hook -

B Flat jet regulation 1248-U6

C Round jet regulation 1240-U5

D Spring pressure reinforcement 1236-5

E Swivelling air connection 1133-U11

F Ball bearing material connection 1248-U7

G Trigger 1248-U4

H Trigger lock 1237-3

I Filter 1233-75

J Air cap 1248-U2

K Nozzel carrier 1248-U8

L Closing piece 1240-7

M Union nut 1248-4

Table to illustration 1/ paint spray gun optima 2100

Illustration 1/paint spray gun optima 2100

7. Start-up

Before the first use, flush the material supply inclusive nozzle with solvent resp. cleaning agent.

Material flow and spraying picture depend on the size of the spray nozzle, the material viscosity

and the material pressure. See nozzle selection table, page 12 – table 2 “trouble-shooting page 10”.

8. Operation

8.1 Air connection

Swivelling air connection 1133-U11, connecting thread G ¼ “ Air supply for flat jet air cap and round jet air.

- clean and dry air increases your spraying quality and extends the life span of your high pressure spray gun.

8.2 Paint connection

(- Attention high pressure!! – Consider all safety regulations)

Swivelling material connection 1248-U7, Connecting thread NPSM ¼ “. Use only permissible high-pressure hose.

Take care of the right position of the ball-cone seal.

8.3 Operation of the high pressure spray gun

a) Turn trigger lock 1237 - 3

90 degrees downwards (Spray gun is now released)

b) Pull trigger 1248 - U4 up to the first pressure point (pre-air)

c) Pull trigger 1248 - U4 completely, high pressure colour jet starts

d) After ending the spraying procedure secure spray gun at all times

by turning the trigger lock 90 degrees upwards again

(see illustration 1).

Note:

In order to avoid a drop formation at the spray gun keep the pre air valve

1-2 sec. after spraying open.

8.4 Flat jet regulation

By means of the flat jet regulation 1248-U6 atomization air is added to the flat jet.

Clockwise rotation little air - little atomization

Counter clockwise rotation - much air - high atomization.

Loading...

Loading...