Maintenance

Version 1.0.3 - 2022-04-06 47Translation of original instruction

D17 Pro│D23 Pro│D26 Pro│D33 Pro EN

D17Pro_D23Pro_D26Pro_D33Pro_GB_6.fm

WARNING!

Before starting the machine you must be sure that

no dangers generated for persons,

the machine is not damaged.

6.2 Inspection and maintenance

The type and level of wear depends to a large extent on the individual usage and operating

conditions. Any indicated intervals therefore are only valid for the corresponding approved con

-

ditions.

Interval Where? What? How?

Start of shift

After each

maintenance or

repair work

Drilling machine

Examination for outside damages.

Safety check on page 12

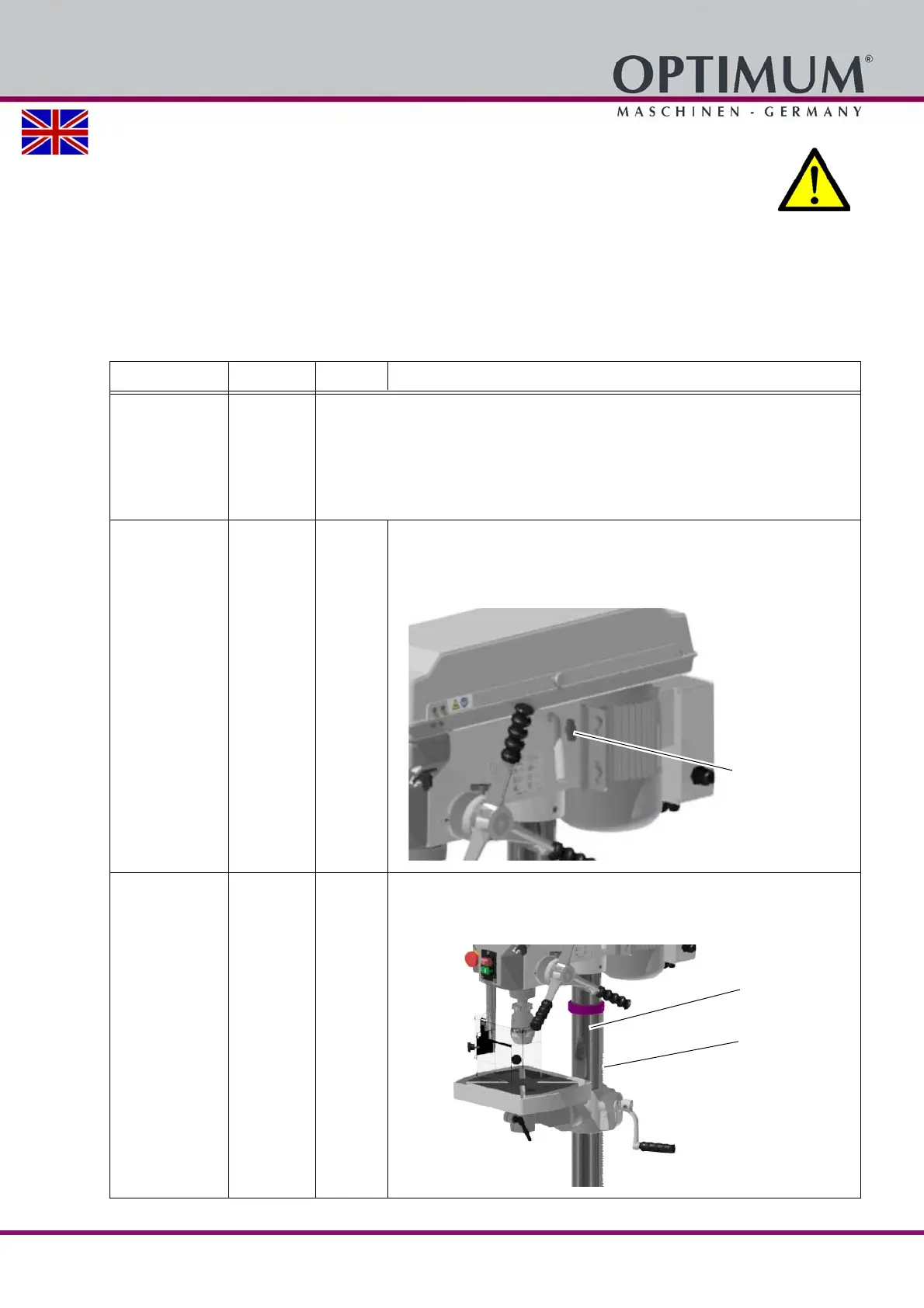

weekly

Slide rail screws

Loosening

Check if the slide rail screws for the V-belt tension on the left

and right side of the drilling head are well fastened.

Check if the V-belts are well tightened. Checking the tension

of V-belts,

Speed variation on page 37.

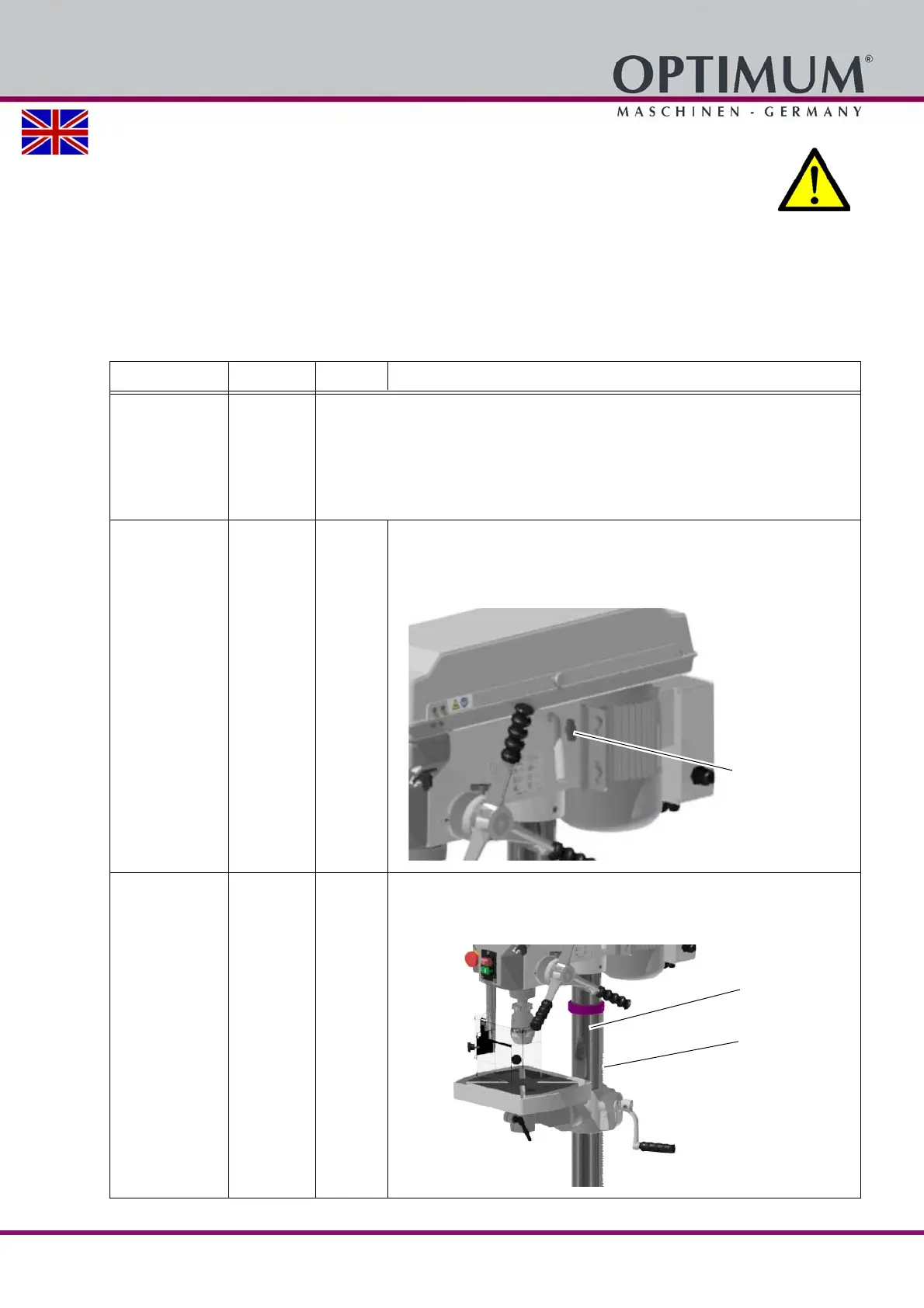

Every month

Drill column and toothed rack

Oiling

Lubricate the drill column regularly with commercial oil.

Lubricate the toothed rod regularly with commercial grease

(e.g. friction bearing grease).

Right-hand side

slide rail screws

Drilling column

Toothed rod

Loading...

Loading...