Malfunctions

Version 1.0.3 - 2022-04-06 74 Translation of original instruction

D17 Pro│D23 Pro│D26 Pro│D33 Pro

EN

D17Pro_D23Pro_D26Pro_D33Pro_GB_8.fm

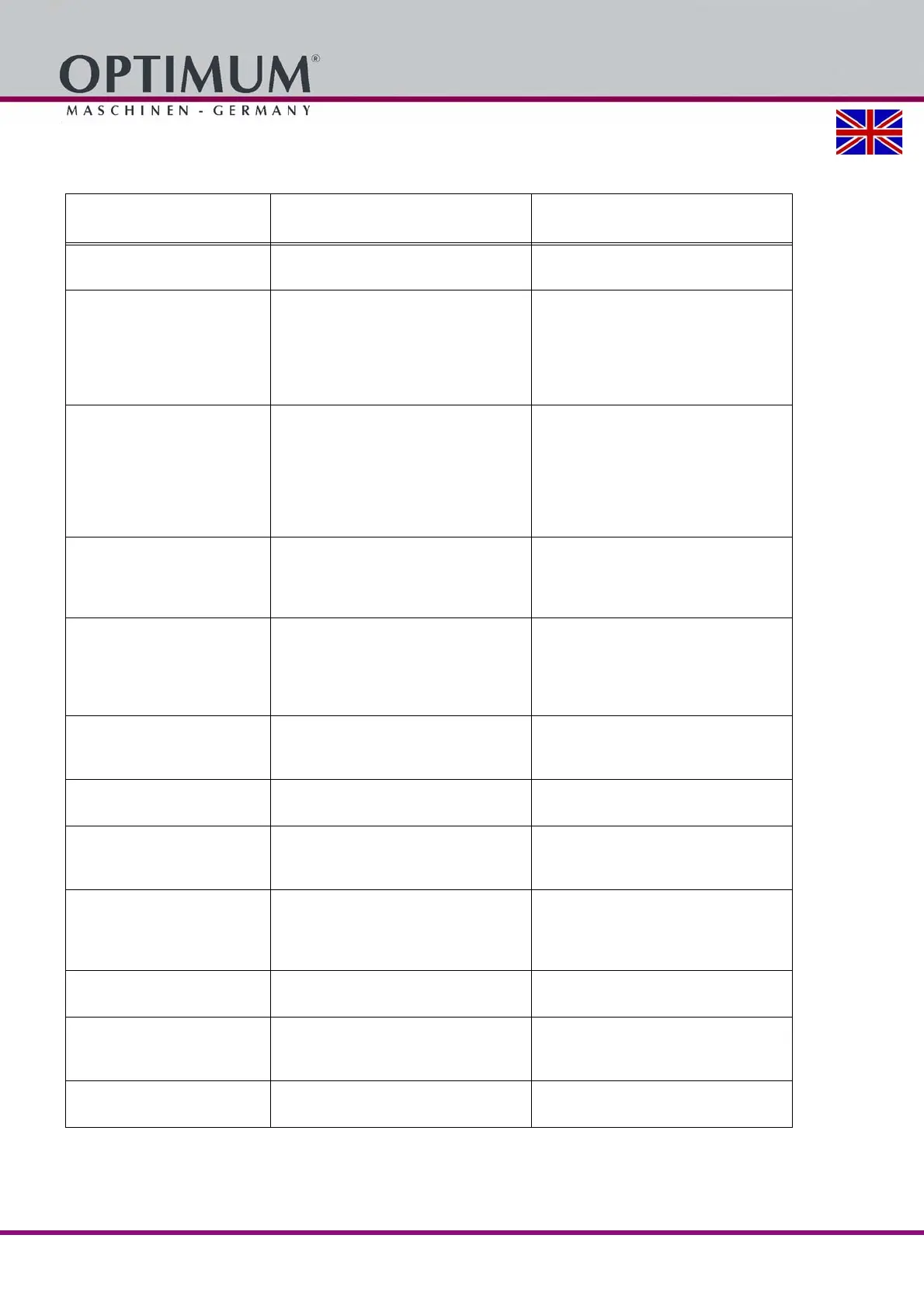

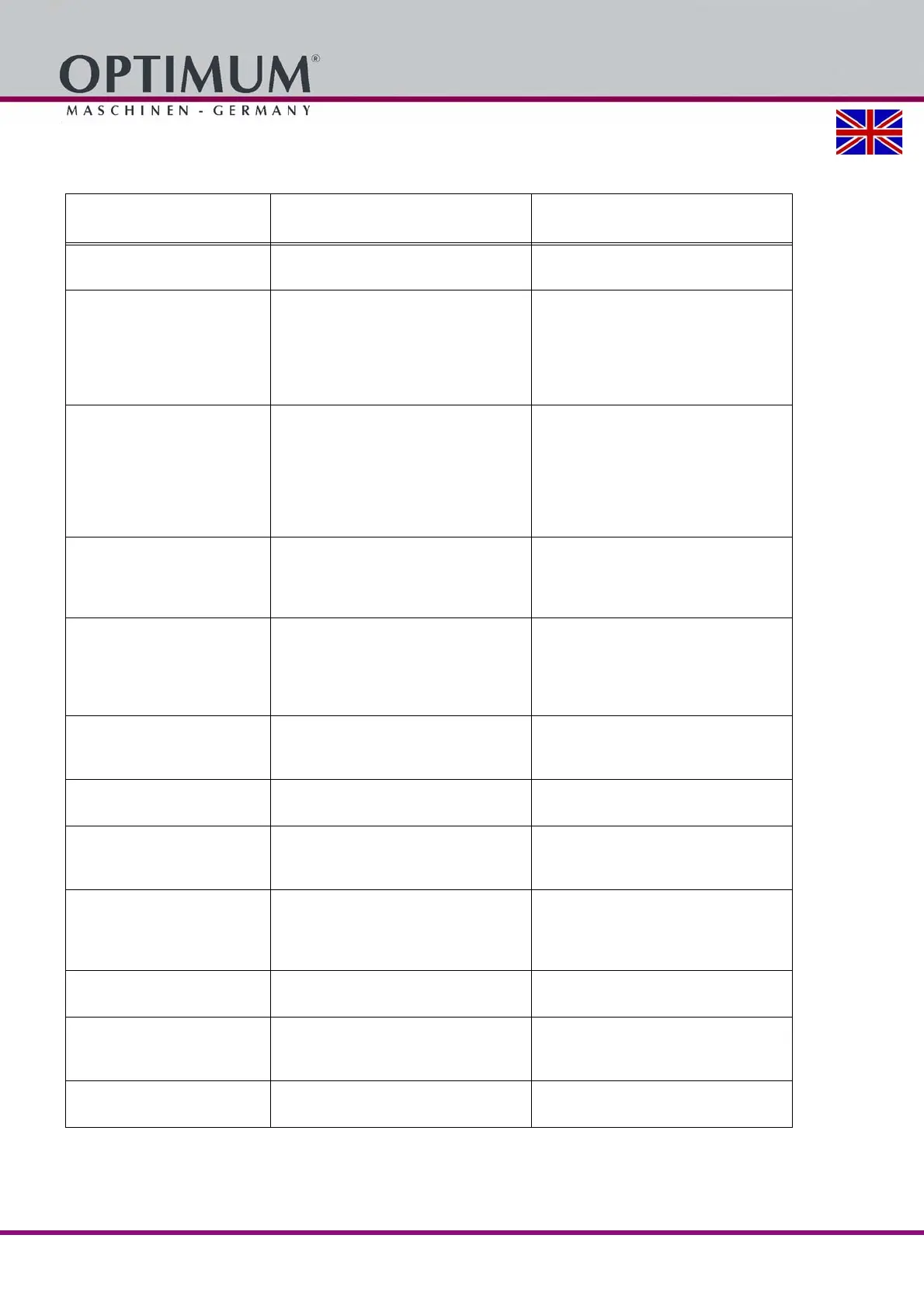

8 Malfunctions

Malfunction

Cause/

possible effects

Solution

Motor is hot • Wrong electrical connection of 400V

machines

•

Noise during work. • Spindle runs dry.

• Tool blunt or incorrectly clamped.

• Pulley on the motor has come

loose.

• Grease spindle

• Use new tool and check tension

(fixed setting of the bit, drill chuck

and taper mandril)

• Check the fastening of the pulley,

tighten the fastening nut.

Bit „burnt“ • Incorrect speed

• Chips are not coming out of the

drilled hole.

• Blunt drill bit.

• Operating without cooling agent.

• Choose a different speed, exces-

sive feed.

• Retract the drill bit from the bore

hole more often.

• Sharpen the drill bit or insert new

drill bit.

• Use coolant.

Drill point runs off, drilled hole

is not circular.

• Hard material or length of the cut-

ting spirals/or angles on the tool are

unequal

• Drill bit is bent.

• Use a new drill bit.

Drill is running non-round or

shaking

• Drill bit is bent.

• Bearings worn down in the spindle

head.

• Drill is not correctly clamped.

• Drill chuck defective

• Replace drill bit

• Have the bearings in the spindle

head replaced.

• Clamp the drill bit properly.

• Replace the drill bit chuck.

The drill chuck or the taper

mandrel cannot be inserted.

• Dirt, grease or oil on the taper

inside of the drill chuck or on the

taper surface of the drill spindle

• Clean surfaces well.

• Keep surfaces free from grease.

Motor does not start. • Motor is wrongly connected

• Defective fuse.

• Have it checked by qualified per-

sonnel.

Motor is overheating and

there is no power.

• Motor overloaded?

• Too low mains voltage

• Motor is wrongly connected

• Switch off immediately and have it

checked by qualified personnel

Precision of the work deficient • Heavy and unbalanced or deformed

work-piece.

• Inexact horizontal position of the

work-piece holder.

• Balance the piece statically and

secure without straining

• Adjust workpiece-holder

Drilling spindle sleeve does

not return to its initial position

• Spindle return spring •

„Img. 6-2: Spindle return

spring“ on page 48

Digital readout does not

match the spindle sleeve

travel

• Encoder (potentiometer) for drilling

depth electrical or mechanical

faulty.

• Check encoder (potentiometer),

replace if necessary.

Digital speed does not match

the speed table

• Deviations of ± 100 1 / min not

uncommon.

• not possible

Loading...

Loading...