Maintenance

Version 1.0.3 - 2022-04-06 50 Translation of original instruction

D17 Pro│D23 Pro│D26 Pro│D33 Pro

EN

D17Pro_D23Pro_D26Pro_D33Pro_GB_6.fm

INFORMATION

The spindle bearing is lifetime-lubricated. It is not necessary to lubricate it again.

in case of need

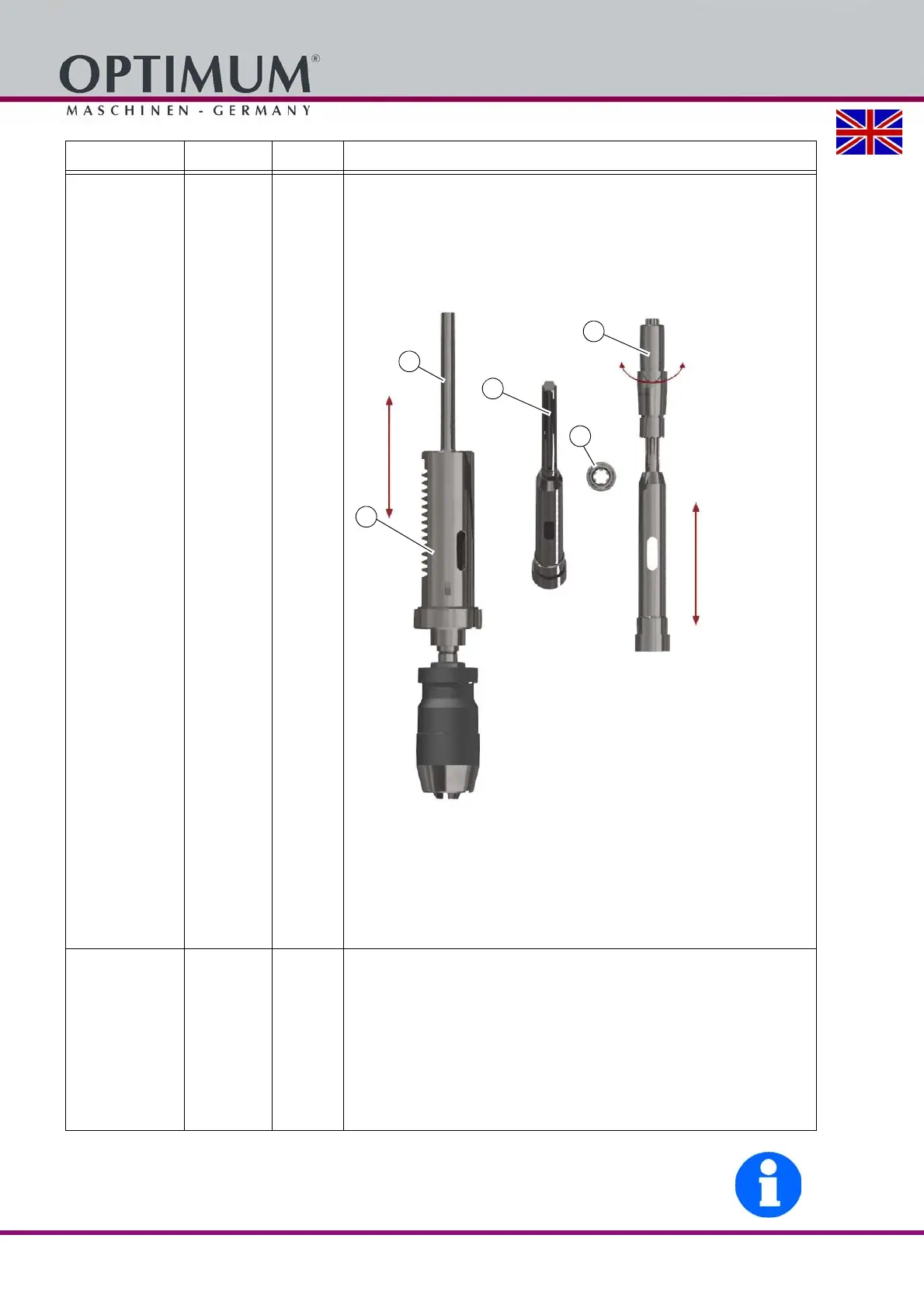

Toothing of the spindle

Lubrication

Any unusual rattling noises can be eliminated by regreasing. The

sleeve (1) moves downwards or upwards with the toothed spindle

(2) in the fixed driven sleeve (3) during drill feed. The noises are

caused by the necessary clearance between the two toothings of

the sleeve and spindle. The grease in the delivery condition may

have been used up.

Img. 6-3:

Regreasing is carried out from above via the spindle drive. Apply

grease at the visible toothed area of the spindle. It is

recommended to use a grease which can remain permanently

inside the toothing. The grease "Staburag NBU 30 PTM" from

Klüber is recommended and has proved to be a successful

assembly grease for clearance fits.

based on operator's

historic values

in accordance with

German DGUV (BGV A3)

Electronics

Electrical inspection

Obligations of the User on page 10

Electronics on page 15

Interval Where? What? How?

Loading...

Loading...