Malfunctions

Version 1.1.4 - 2022-09-2324 Originalbetriebsanleitung

GH 10T | GH 15T

EN

GH10T_GH15T_GB_4-1.fm

5 Malfunctions

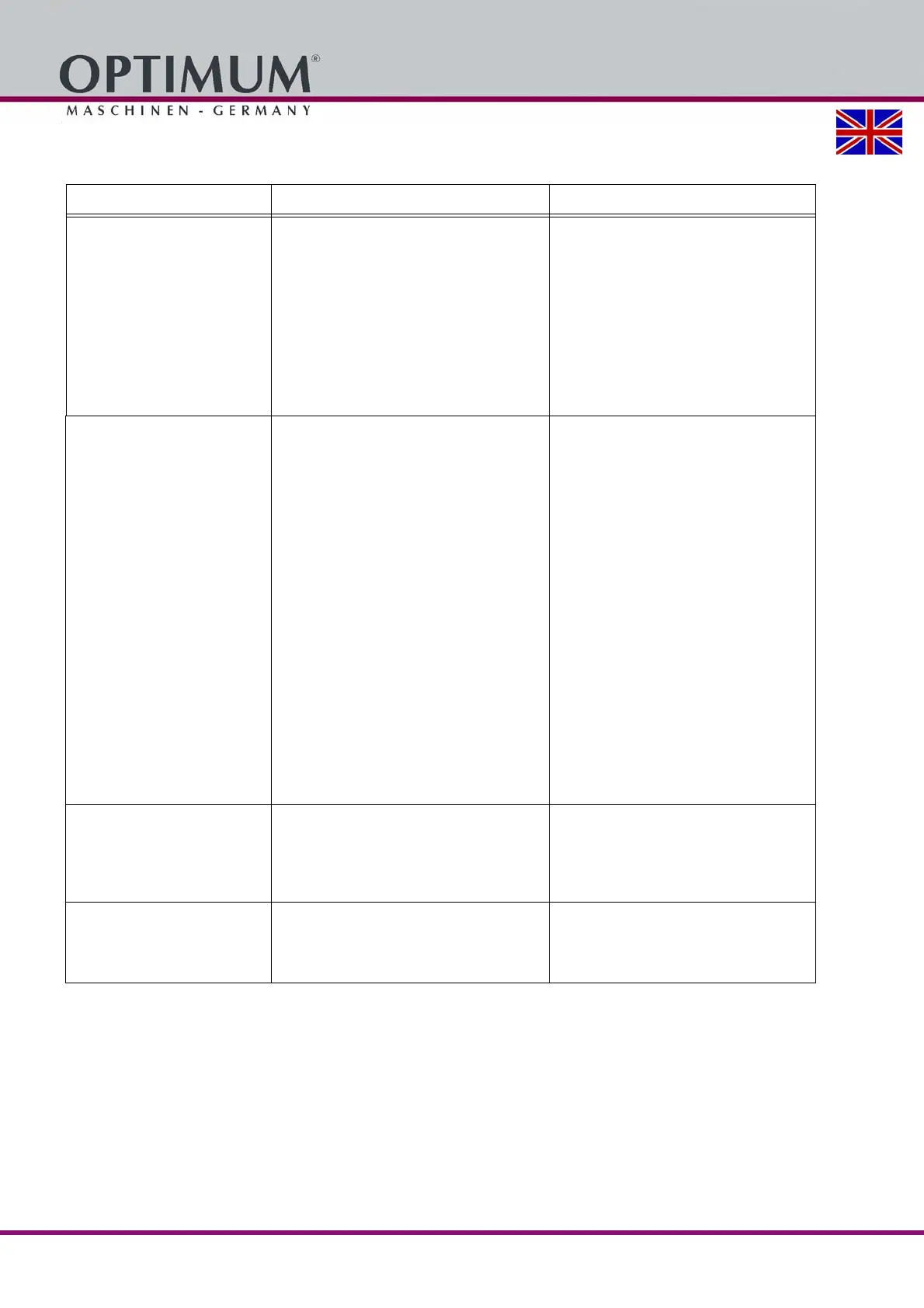

Malfunction Cause/possible effects Solution

Motor does not turn on • Micro fuse 1F1 defective at the freezer

plug connection.

Schaltplan - Wir-

ing diagram - GH10T , GH15T on

page 38

• Cover item 51 not completely closed,

micro switch on GH15T item 24 is not

pressed.

• Carbon brushes item 49 worn

• Unit not cleaned of grinding dust.

• Motor defective

• Determine the cause, where appro-

priate have this checked by a trained

specialist.

Replace micro fuse.

• Close cover completely, check micro

switch.

• Replace carbon brushes

•

Inspection and maintenance on

page 25

• Replace motor

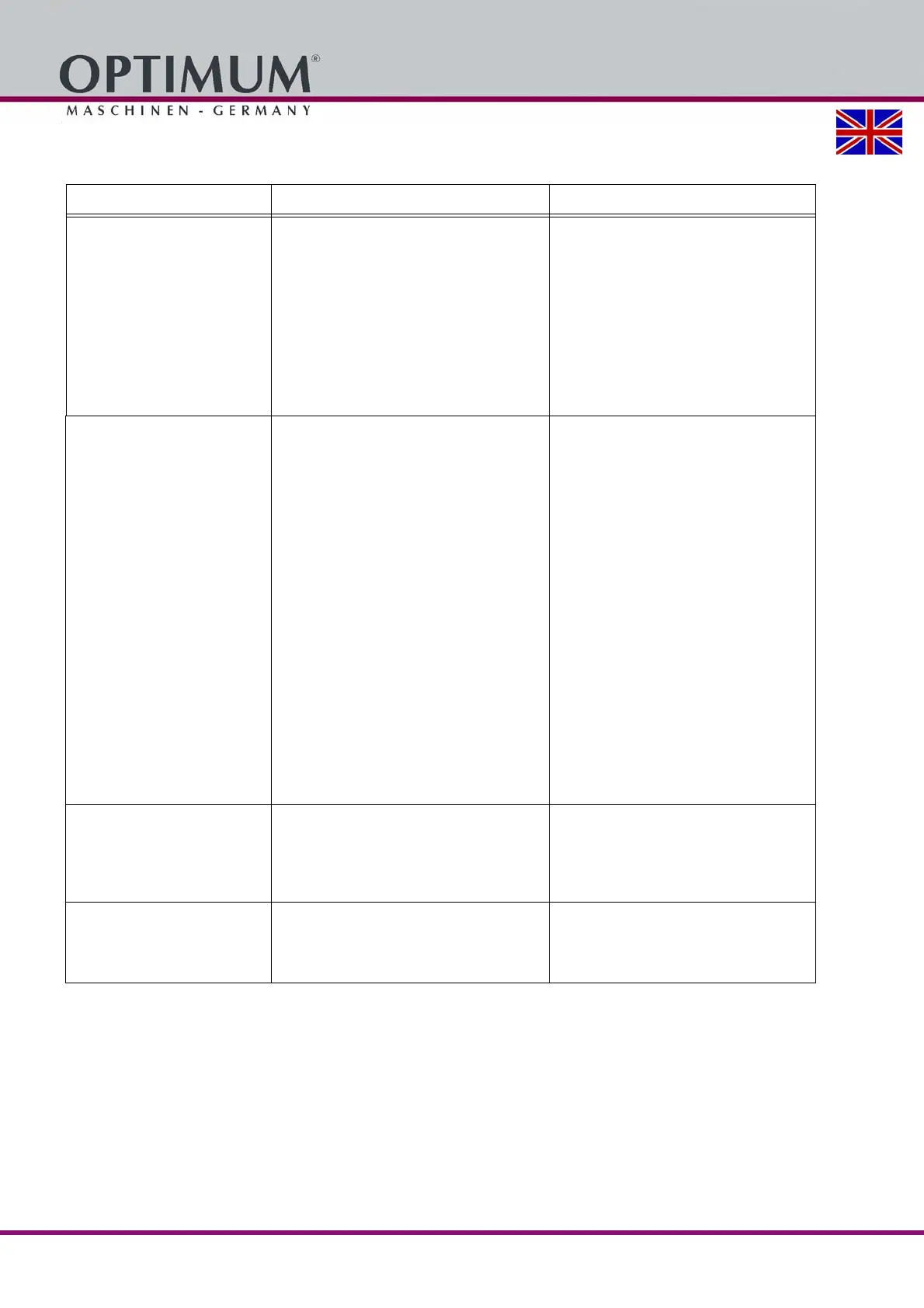

Drills become eccentric, tips

no longer true.

Drills cannot be centred; after

sharpening, the tip is not

centred.

Incorrect drill grinding,

geometry not true.

No back cut on the drill; the

drill does not cut after

regrinding.

Drills are not back cut.

Appliance is grinding the drills

wrongly, clearance angle

incorrect.

• Incorrect operation and maintenance

of the appliance

• Drill diameter adjusting screw not set

correctly.

• Drill stop edge and clamping head

group stop surface neglected during

setting.

• Turn the chuck in the housing

through 180° and grind both sides of

the drill until a grinding noise is no

longer audible.

• Drill is not clamped correctly in the

chuck.

• Drill is moved by contact pressure

while grinding in the chuck, because

the grinding disk is worn

• The chuck has not been inserted

correctly in the clamping head group.

• Set the drill diameter correctly. Con-

sider the backlash of the thread in

the adjusting screw. The smaller the

drill, the more difficult the setting.

• Observe the required stop areas

while setting, the cutting edge of the

drill and stop area at the clamping

head group.

• Flying sparks detectable with HSS

spiral drills? No, grinding disk is

worn and must be replaced.

Clamping head group cannot

be placed in its housing, or

only with difficulty.

• New appliance, new parts, as yet no

wear on the surfaces.

• Surfaces covered with grinding dust.

• Reduce and round the diameter of

the housing or the clamping head

group bevel with 120 grain emery

cloth.

• Clean the surfaces, use some oil.

The wear of the steel disk,

coated with cubic crystalline

boron nitride is too great.

• Regrinding of spiral drills with hard

metal tips (hammer drills). The life of

the grinding disk with HSS spiral drills

is much higher.

• Use of an SDC grinding wheel, see

spare parts

Loading...

Loading...