21

OWNER SERVICE

Cleaning

After Each Use

• Remove large debris such as clumps of dirt, grass, crop

residue, etc. from machine.

• Inspect machine and replace worn or damaged parts.

• Replace any safety decals that are missing or not readable.

Periodically or Before Extended Storage

• Clean large debris such as clumps of dirt, grass, crop

residue, etc. from machine.

• Remove the remainder using a low-pressure water spray.

1. Be careful when spraying near scratched or torn safety

decals or near edges of decals as water spray can peel

decal off surface.

2. Be careful when spraying near chipped or scratched

paint as water spray can lift paint.

3. If a pressure washer is used, follow the advice of the

pressure washer manufacturer.

• Inspect machine and replace worn or damaged parts.

• Sand down scratches and the edges of areas of missing

paint and coat with Oregon spray paint of matching color

(purchase from your Oregon dealer).

• Replace any safety decals that are missing or not readable

(supplied free through your Oregon dealer).

See Safety Decals section for location drawing.

• Lower skid shoes and park stand to the lowest position for

stability during storage.

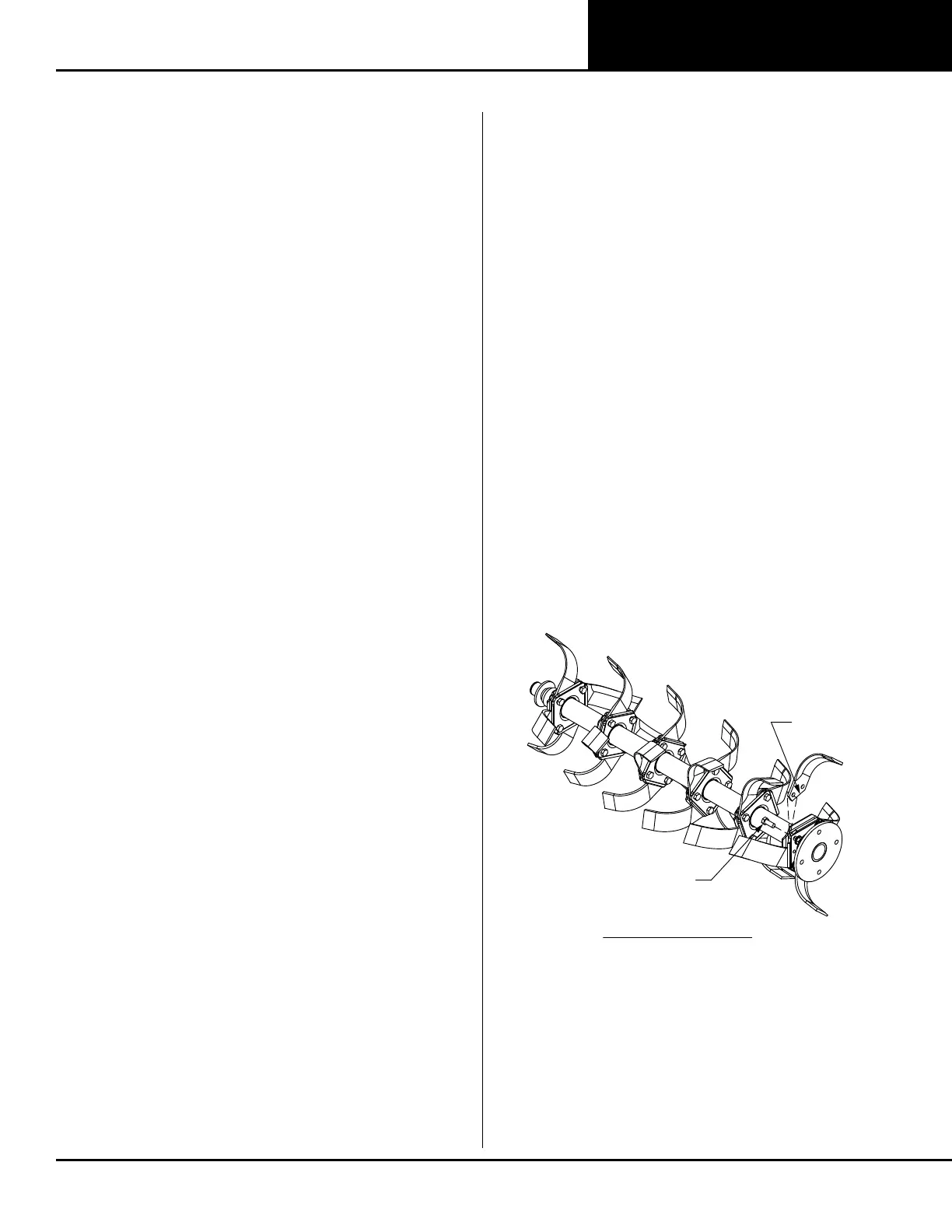

Blade Installation

Four Blade Installation

1. Remove any burrs on flanges generated from blades that

have slipped.

2. Start blade assembly with first blade installed next to rotor

shaft flange.

Blade cutting edges should face the direction

of rotation.

3. Install blade inside flange pocket with blade hole closest to

end matching holes in flanges.

4. Install bolt through flange, blade, flange, and nut but do not

tighten completely.

5. Rotate blade backwards until blade profile is seated on

flange embossments in the flange pockets.

6. Tighten bolted joint to 140 lbs-ft.

7. Proceed by installing next blade of the same part number

in next flange.

8. Repeat steps 2-7 installing opposite hand blade in next

flange hole until all four rows of blades are installed.

Figure 16. Four Blade Forward Rotation Blade Installation

TIGHTEN TO

140 LBS-FT

INSERT BLADE PROFILE

INTO FLANGE POCKET

AGAINST EMBOSSMENT

INSERT BLADE PROFILE

INTO FLANGE POCKET

AGAINST EMBOSSMENT

TIGHTEN

TO 140 LBS-FT

FORWARD ROTATION

Loading...

Loading...