21

OrionWelders.com

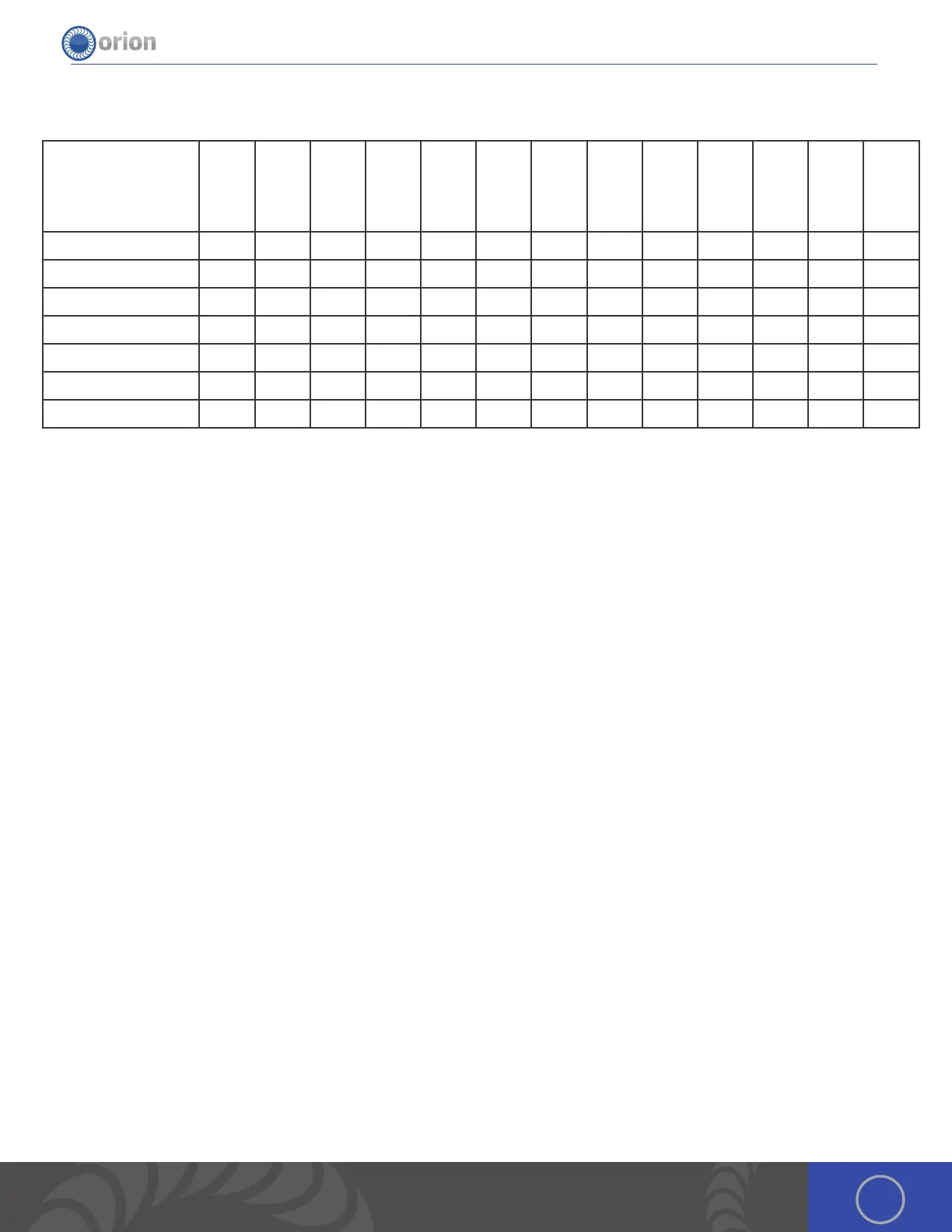

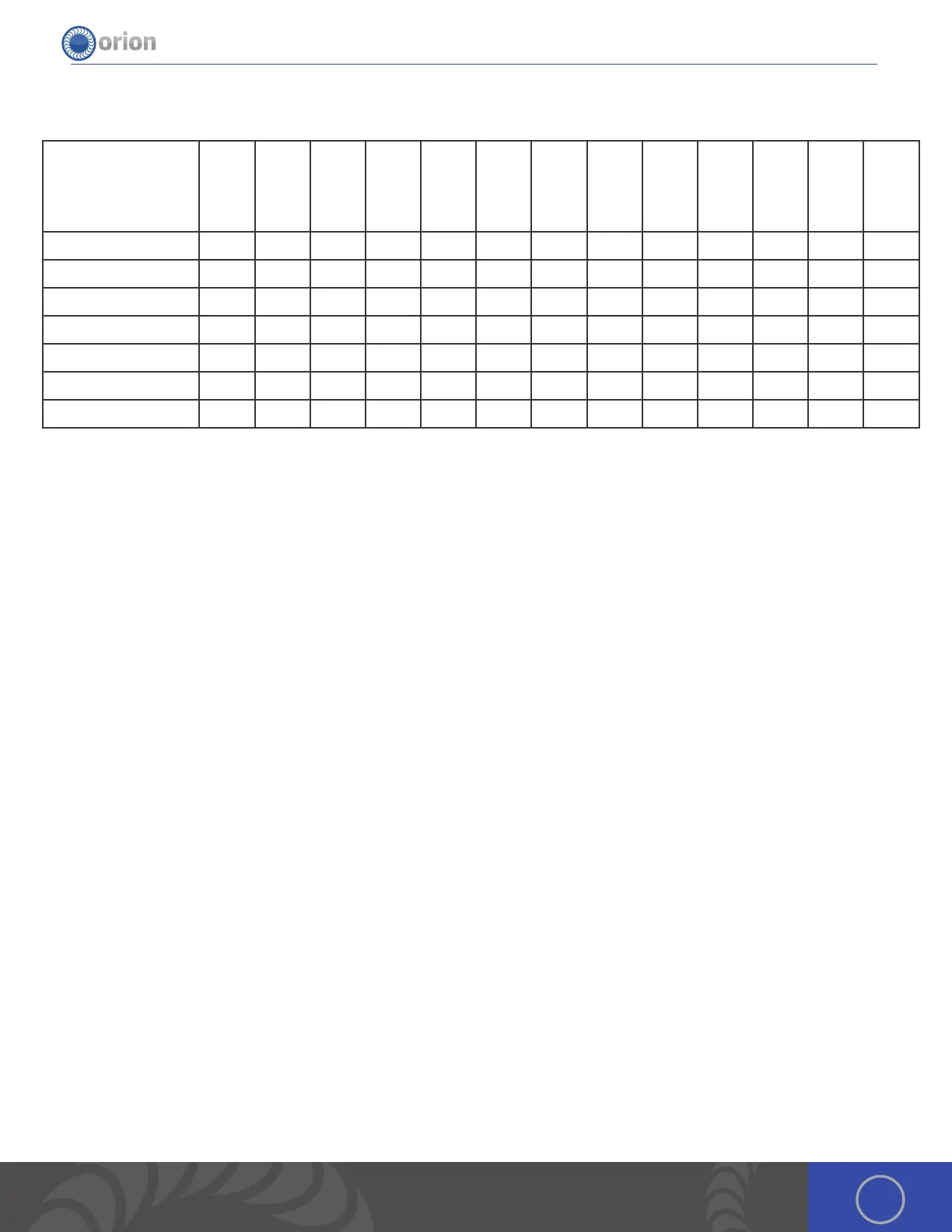

of some common metals. ese metals have been arranged by melting temperature for convenience. Each of the

properties listed below will have an effect of the weldability of the metals.

Zinc

Aluminum

Silver

Gold

Copper

Palladium*

Cobalt

Chrome*

Stainless

304*

Carbon

Steel

Titanium

Platinum

Niobium

Tungsten

Melting Point 420 660 962 1064 1083 1200 1300 1450 1500 1660 1772 2468 3410

Boiling Point 607 2467 2212 3080 2567 3100 2800 3000 3000 3287 3827 4742 5660

Specific Heat 388 900 237 129 385 244 10 500 500 523 129 268 133

Electrical Resistivity 6 2.7 1.6 2.2 10.6 10.8 475 70 60 54 10.6 16 5.4

Density 7.1 2.7 10.5 19.3 9 11 8.3 7.9 7.8 4.5 21.5 8.6 19.3

ermal Expansion 31 23.5 19.1 14.1 17 11 10 18 12 8.9 9 7.2 4.5

ermal Conductivity 116 237 429 318 401 71 100 16.3 50 22 71.6 54 173

*Some Values may be approximate

DEFINITIONS:

Melting Point: e temperature at which the metal will begin to melt. e molten metal of the weld pool will be at this

temperature during the welding process.

Boiling Point: If enough energy is added to the weld joint (and heat is removed slowly by the surrounding solid metal)

the weld puddle can begin to boil. Liquid metal will be turned into gaseous metal.

Specific Heat: e energy required to raise the temperature of the metal (per unit mass). ink of this number as how

much metal will melt for a given weld energy (melting point also is important). A larger specific heat means more

energy is required to melt the metal.

Electrical Resistivity: is number represents the resistance to the flow of electrons in a metal. is property

is especially important during a resistance or “tack” weld. e more resistive the metal is the more easily it will

resistance weld (e.g. stainless steels), the smaller this number is the more difficult it will be to weld the material (e.g.

silver), especially in “tack” mode.

Density: how much of the metal (atoms / mass) is in a given volume of space. is property will also influence how

large the weld spot is for a given metal. All other things being equal, a lower density metal will have a larger weld spot

than a higher density metal for the same weld energy.

Thermal Expansion: When a metal is heated it will expand, or elongate slightly. In some situations, especially during

resistance welding, metal can expand quickly and spill out of the weld joint.

Thermal Conductivity: This is a measure of how fast the metal conducts heat. Metals that are good conductors

of heat (e.g. copper) will dispel the heat away from the weld location quickly during the welding process. is action

reduces the size of the weld spot. Metals that are poor conductors of heat (e.g. titanium) are slow to conduct heat

away from the weld location and the weld energy has a greater affect on the weld size, etc.

Loading...

Loading...