49

REV. 00 - Cod.: 1500154

Operation and maintenance manual / Ed. 10 - 2005

VACUUM CHAMBER

PACKAGING MACHINES

GB

GB

GB

INSTALLATION

•

•

•

•

•

•

•

51 64 3 8 7

2

•

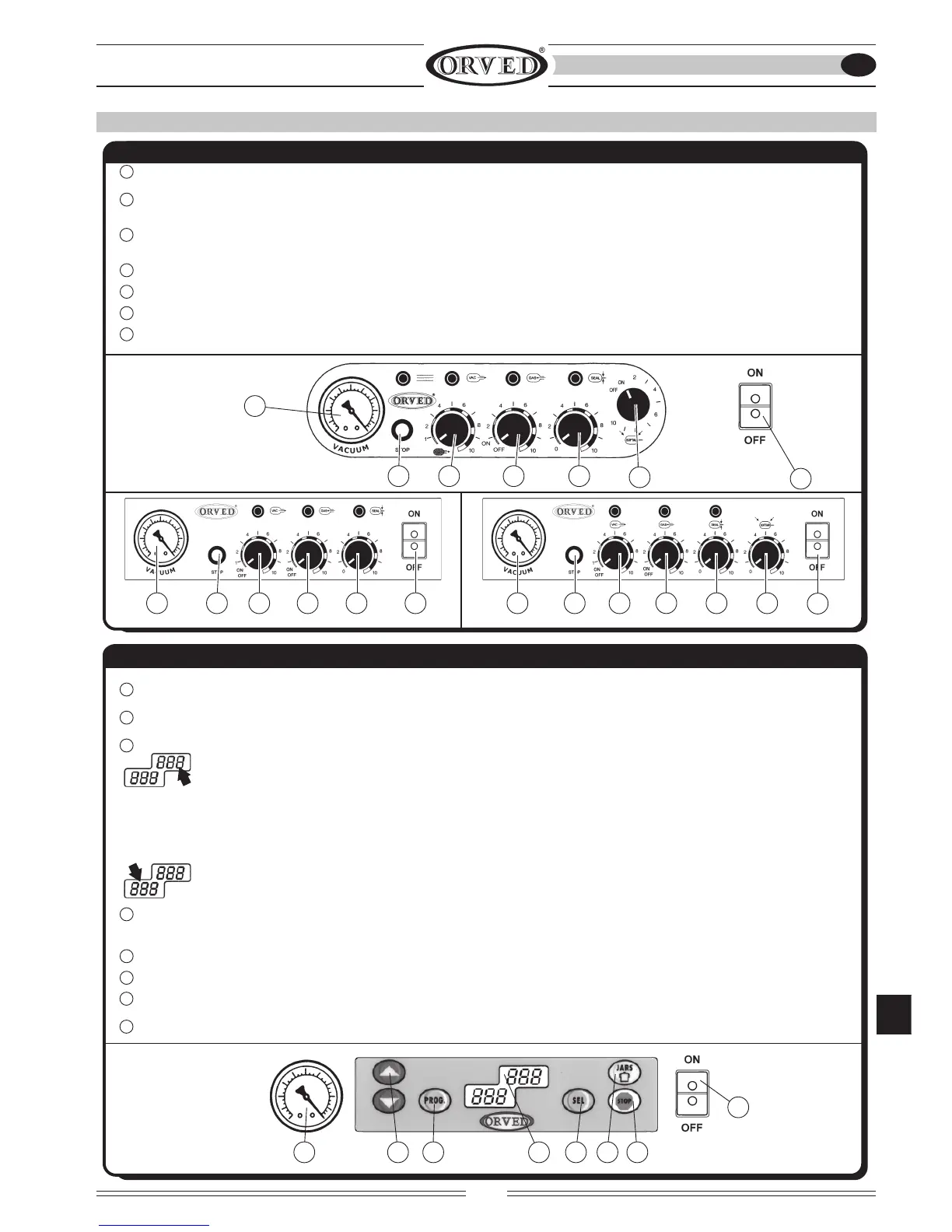

MULTIPLE 315 P4/P8 - VM12 - VM16 WITH DIGITAL CONTROLS

1 VACUUM GAUGE ( 0÷1 bar ): MEASURES VACUUM IN THE VACUUM CHAMBER.

2 ON/OFF - MAIN SWITCH WITH RED INDICATOR LED:

MACHINE ON/OFF AND INTERRUPT CYCLE.

3 THREE-DIGIT DOUBLE DISPLAY

- TOP THREE DIGITS: INDICATE THE PROGRAM ENTERED OR FUNCTION ACTIVATED:

Pr1 = PROGRAM SELECTED

VAC = VACUUM

SAL = SEALING

GAS = GAS INLET

SOF = SLOW AIR RETURN

JAR = JARS FUNCTION - (EXTERNAL CONTAINERS AND CHANNELLED BAGS VACUUM).

- BOTTOM THREE DIGITS: INDICATE THE VALUE RELATIVE TO THE FUNCTION ACTIVATED AND THE CODE OF THE OPTIONS

AVAILABLE: G = GAS / S = SOFTAIR; ALSO INDICATES THE NUMBER OF CYCLES PERFORMED AND THE OIL CHANGE ALARM.

4 CURSOE: PROGRAM SELECTION FROM “0” TO “9”;

INCREASES/DECREASES THE VALUE OF EACH FUNCTION IN THE PROGRAM.

5 PROG - PROGRAMMING BUTTON: MAKES IT POSSIBLE TO ENTER PROGRAMMING OF THE INDIVIDUAL FUNCTIONS

6 SEL - FUNCTIONS SELECTION KEY: SELECTS THE FUNCTION TO BE PROGRAMMED

7 JARS - KEY FOR ACTIVATING VACUUM INSIDE OUTSIDE CONTAINERS AND/OR CHANNELLED BAGS:

ACTIVATES/ DEACTIVATES THE EXTERNAL EVACUATION SYSTEM OF CONTAINERS AND/OR CHANNELLED BAGS

8 STOP - STOP BUTTON: STOPS THE WORK CYCLE

6

•

•

53 42

1

1 2 3 4 5 6

7

•

•

53 42 71

7

VM18

VM20

VM53

VM53H

VM30

VM1800

VM19

VM12 VM16

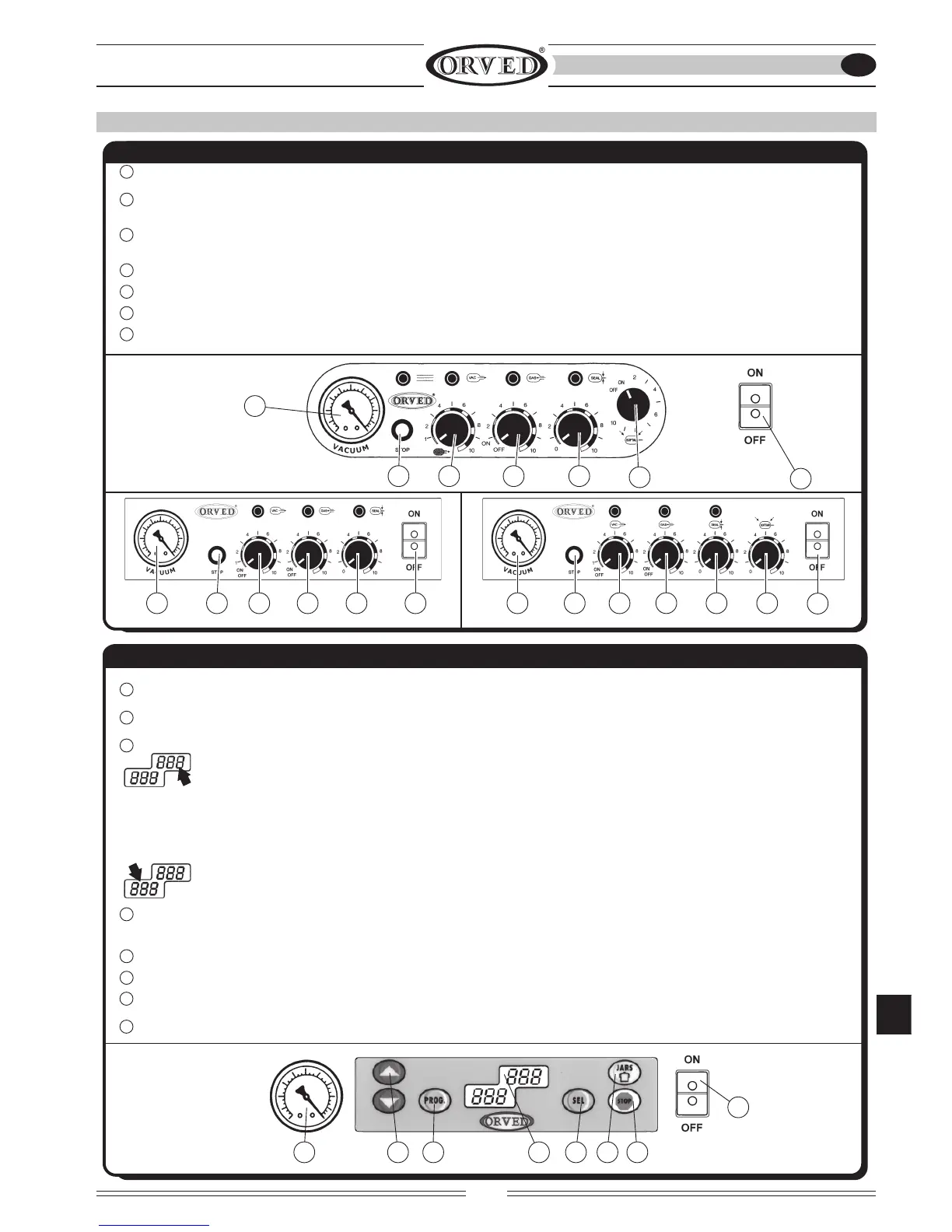

5.4 CONTROL PANEL

VM12/VM16/VM18/VM18H/VM40N/VM53/VM53H/VM19/VM1800/VM20/VM30 WITH ELECTRO-MECHANICAL CONTROLS

1 VACUUM GAUGE ( 0÷1 bar ): MEASURES THE VACUUM IN THE VACUUM CHAMBER.

2 STOP - STOP BUTTON: STOPS THE OPERATING PHASE AND PROCEEDS TO THE NEXT ONE SET;

FOR 380V VERSIONS: IF PRESSED FOR 3 SEC. THE PUMP FUNCTION IS ACTIVATED (CONTINUOUS OPERATION)

3VAC- VACUUM ADJUSTMENT CONTROL KNOB: ADJUSTS THE PUMP OPERATING TIME TO MAKE IT POSSIBLE TO OBTAIN THE

REQUIRED DEGREE OF VACUUM.

4 GAS - GAS ADJUSTMENT POTENTIOMETER (OPTIONAL): ADJUSTS THE QUANTITY OF GAS DELIVERED.

5 SEAL - SEALING TIME ADJUSTMENT POTENTIOMETER: ADJUSTS THE BAGS SEALING TIME.

6 SOFTAIR - SOFTAIR POTENTIOMETER (OPTIONAL): ADJUSTS THE CHAMBER DEVACUMATE TIME.

7 ON/OFF - MAIN SWITCH: MACHINE ON/OFF AND INTERRUPT CYCLE.

Loading...

Loading...