SWG OPERATOR INSTALLATION GUIDE

- 4 -

USE COPPER WIRE ONLY!

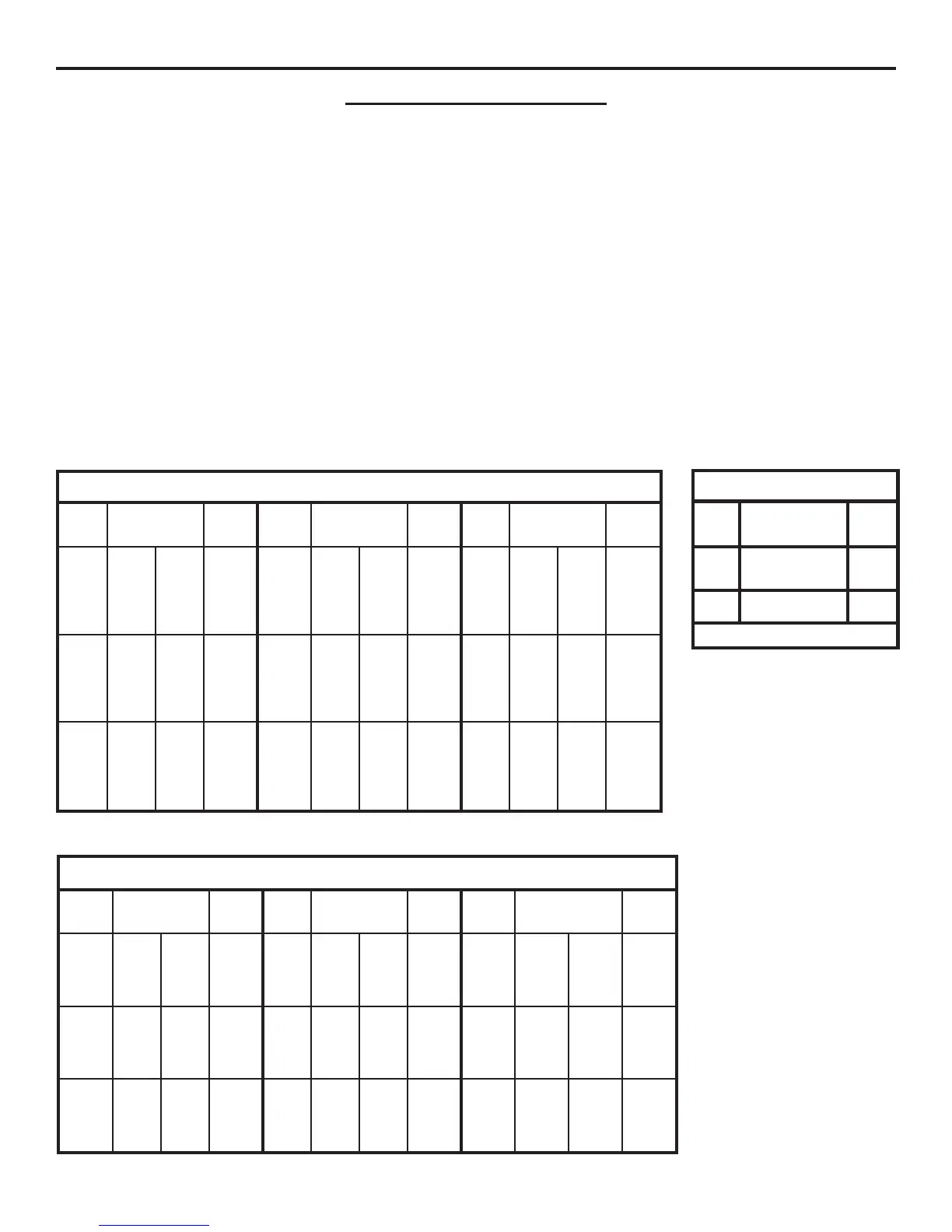

ACCESSORY WIRING

All Models

24VDC

*Over 350 ft. use DC power.

0-2000

14

24VAC

250

350*

14

12

Volts

Maximum

Distance (ft.)

Wire

Gauge

1. Select from the chart at the bottom of this page corresponding to the

model, voltage and horsepower rating of your operator.

2. The distance shown on the chart is measured in feet from the opera-

tor to the power source. DO NOT EXCEED THE MAXIMUM DIS-

TANCE. These calculations have been based on standard 115V and

230V supplies with a 10% drop allowable. If your supply is under the

standard rating, the runs listed may be longer than what your appli-

cation will handle, and you should not run wire too near the upper

end of the chart for the gauge of wire you are using.

3. When large-gauge wire is used, a separate junction box (not sup-

plied) may be needed for the operator power connection.

4. All control devices are now 24VDC, which can be run considerable

distances. 24VAC is available for other devices, such as loop detec-

tors and photo eyes.

5. Wire run calculations are based on the National Electrical Code, Ar-

ticle 430 and have been carefully determined based on motor inrush,

brake solenoids, and operator requirements.

WIRING SPECIFICATIONS

6. Connect power in accordance with local codes. The green ground

wire must be properly connected.

7. Wire insulation must be suitable to the application.

8. Control wiring must be run in a separate conduit from power wiring.

Running them together may cause interference and faulty signals in

some accessories.

9. Electrical outlets are supplied in all 115VAC models for convenience

with occasional use or low power consumption devices only. If you

choose to run dedicated equipment from these devices, it will de-

crease the distance for maximum run and the charts will no longer be

accurate.

10. A three-wire shielded conductor cable is required to connect master

and slave operators. You must use Belden 8760 Twisted Pair Shielded

Cable (or equivalent) only – OSCO part number 2500-1982, per

foot). See page 10 for details of this connection, as well as dip

switch selection. Note: The SHIELD wire should be connected

in both the master and slave operators.

MODEL SWG – SINGLE PHASE

gniriWrewoP

stloV

PH&

ecnatsiDxaM

lauDelgniS

eriW

eguaG

stloV

PH&

ecnatsiDxaM

lauDelgniS

eriW

eguaG

stloV

PH&

ecnats

iDxaM

lauDelgniS

eriW

eguaG

V511

2/1

PH

222

453

665

009

0341

111

771

382

054

517

21

01

8

6

4

V802

2/1

PH

067

0021

4291

0603

4684

083

006

269

0381

2342

21

01

8

6

4

V032

2/1

PH

498

2241

4622

0063

4275

744

117

2311

0081

2682

21

01

8

6

4

V511

4/3

PH

871

282

054

617

0411

98

14

1

522

853

075

21

01

8

6

4

802

4/3

PH

406

859

6251

4242

6583

203

874

367

2121

8291

21

01

8

6

4

V032

4/3

PH

017

8211

6971

2582

8354

553

465

89

8

6241

9622

21

01

8

6

4

V511

PH1

061

452

604

646

6201

08

721

302

323

315

21

01

8

6

4

V802

PH1

445

468

4731

4812

6743

272

234

686

2901

8371

2

1

01

8

6

4

V032

PH1

046

6101

6161

0752

0904

023

805

808

5821

5402

21

01

8

6

4

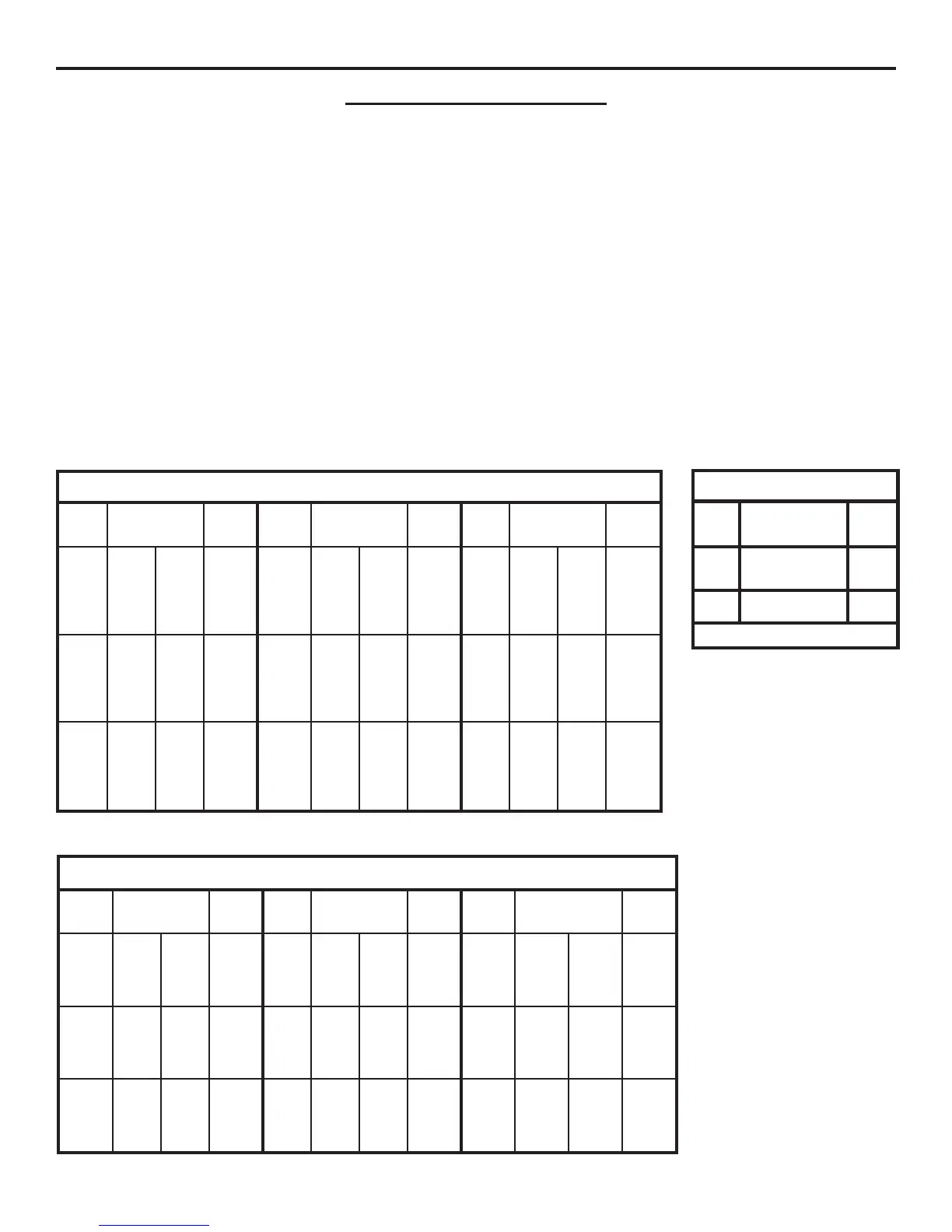

esahP3:gniriWrewoP

stloV

PH&

ecnatsiDxaM

lauDelgniS

eriW

eguaG

stloV

PH&

ecnatsiDxaM

lauDelgniS

eriW

eguaG

stloV

PH

&

ecnatsiDxaM

lauDelgniS

eriW

eguaG

V802

2/1

PH

2411

6181

0982

175

809

5441

21

01

8

V032

2/1

PH

4431

7312

0043

276

9601

0071

21

01

8

V064

2/1

PH

1483

6016

2179

1291

3503

6584

21

01

8

V802

4/3

PH

029

4641

0332

064

237

5611

21

01

8

V032

4/3

PH

4801

3271

1472

245

2

68

1731

21

01

8

V064

4/3

PH

9723

2125

1928

0461

6062

6414

21

01

8

V802

PH1

417

6311

4081

753

865

209

21

01

8

V032

PH1

048

6331

4212

02

4

866

2601

21

01

8

V064

PH1

9862

4724

8976

5431

7342

9933

21

01

8

MODEL SWG – THREE PHASE

12-02-11

Loading...

Loading...