10

Adjusting Pressure Switch

Pressure switches are used to send 12V DC signals to the microprocessor. The remote control uses

hydraulic pressure to tell when one step of the cycle is ended and another needs to start.

To adjust the pressure switches follow these steps. You will need a flat screwdriver.

Note: There are indicator lights on the receiver (white box) that tells you when each pressure switch

is closed. The left one is for the left valve, the right one is for the right valve.

1. Lower the lid.

2. Turn the receiver on.

3. With the lid down push the valve handle away from you and hold, this will allow the

maximum pressure of 2600 psi* to be achieved, then release handle. Each pressure switch is

wired to an indicator light on the receiver box. This light will tell you when the pressure

switch is closed.

4. Slowly push the valve handle away from you and watch the pressure on the gauge. You can

tell what pressure the switch is set at, by looking at the pressure reading on the gauge when

the light comes on. Important: Let the pressure on the gauge rise very slowly.

5. Set both pressure switches at 2400 psi. This means the light will come on at 2400 psi.

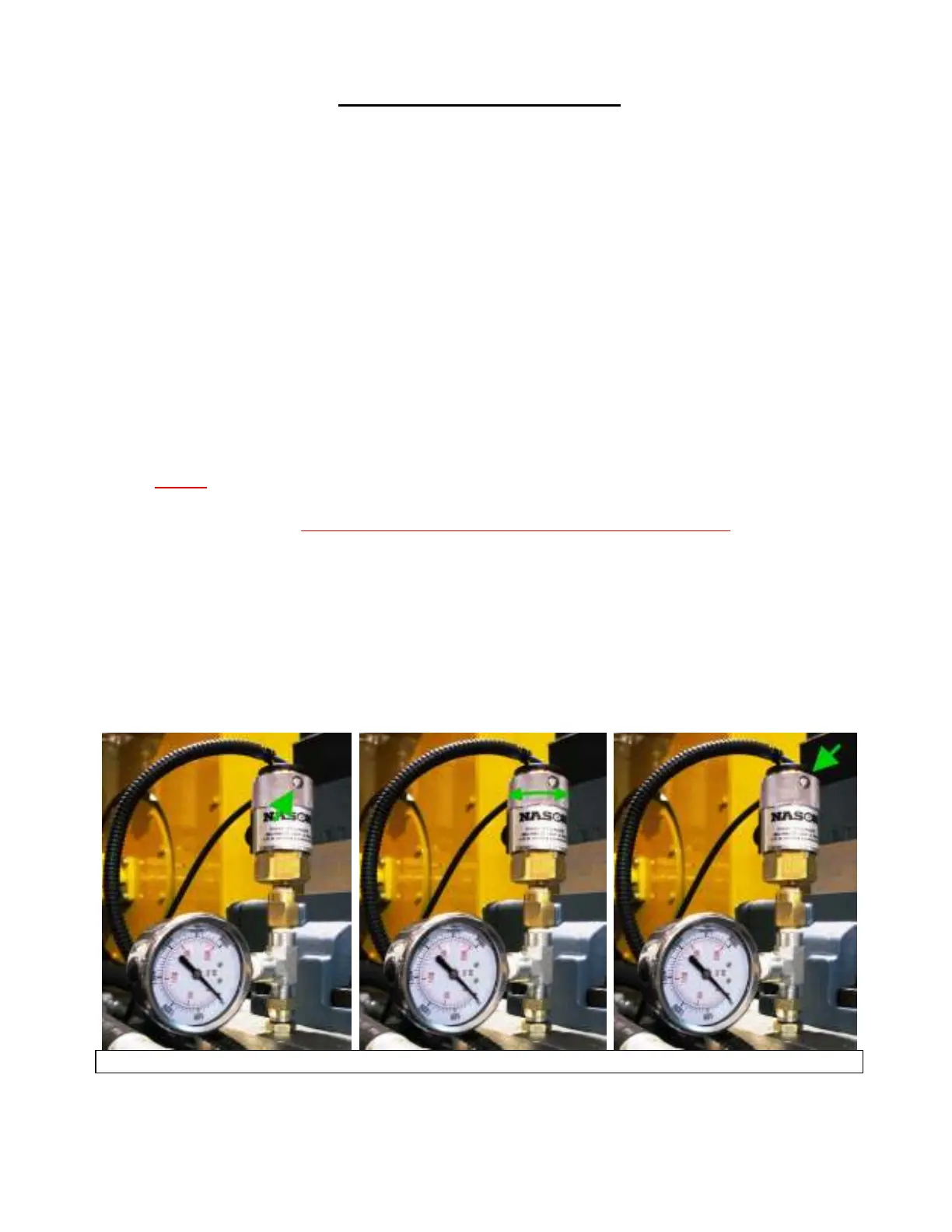

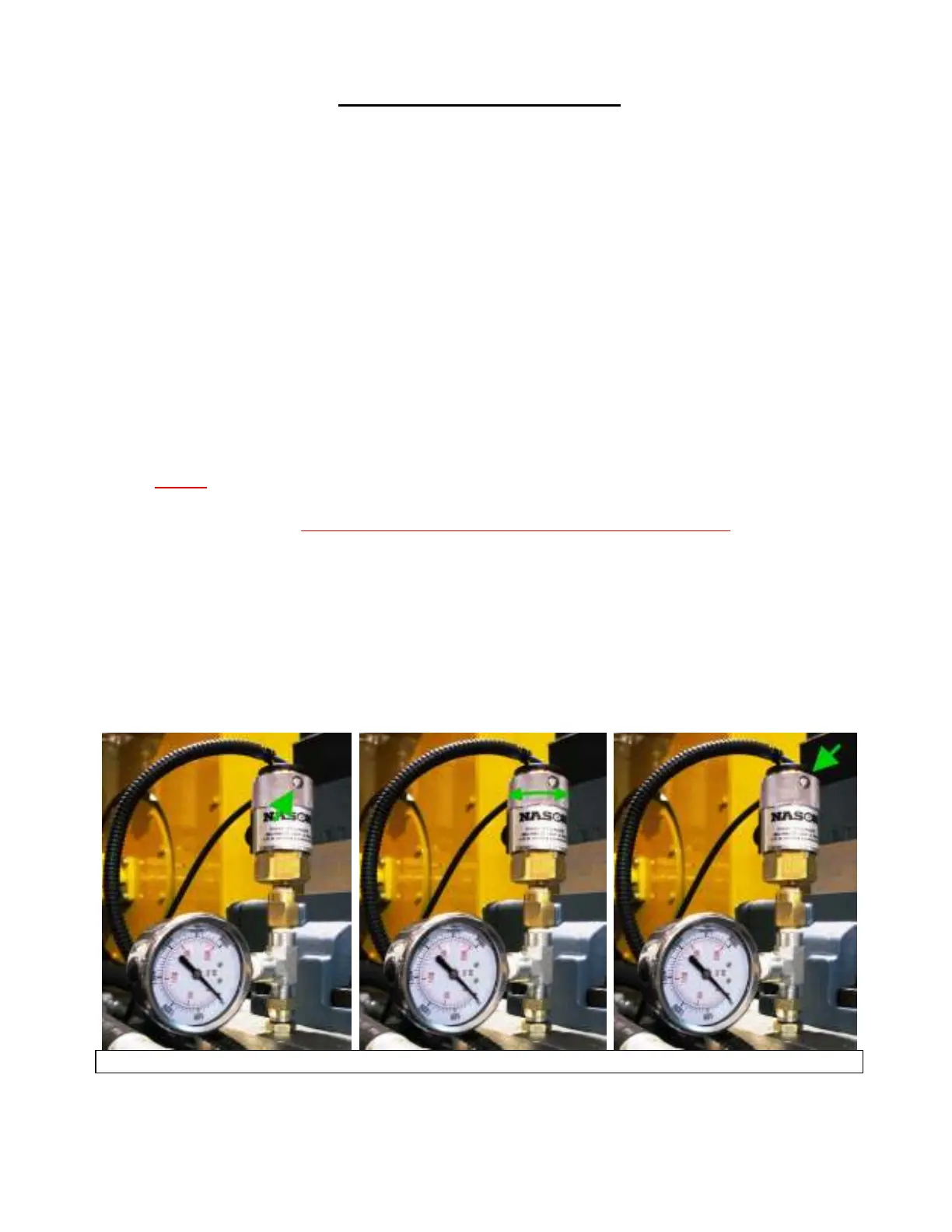

6. To adjust the pressure, loosen the setscrew (flat screwdriver) on the side of the adjustment

ring.

7. Twist the adjustment ring clockwise to increase the release pressure or counterclockwise to

decrease the release pressure.

8. Re-tighten the setscrew.

Loosen the setscrew Twist the adjustment ring Tighten the setscrew

• The gauge should read 2600 psi when the valve is fully open. If it does not, go to the Adjusting

Relief Valves section on page 8.

Loading...

Loading...