6

6-1 THE HYDRAULIC SYSTEM

There are really two separate hydraulic

systems. The hydraulic tandem pump contains

two sections that draw oil from the tank through

two 100-mesh screen filters located inside the

tank. Each section pumps oil into one of the two

4-way control valves. The valves can be

electrically or manually controlled. The two

valves, in turn, control two separate 10” cylinders.

To raise the lid, pull the valve handle

toward you, oil is then sent to the bottom port of

the cylinder, which will force the lid to go up. The

oil in the top of the cylinder is sent through a 10-

micron filter and then to the tank

To lower the lid, push the valve handle

away from you, oil is then sent to the top port of

the cylinder, which will force the lid down. The

oil in the bottom of the cylinder is sent through a

10-micron filter and then to the tank.

When the valve handles are in the center

position oil is sent through a 10-micron filter and

then back to the tank.

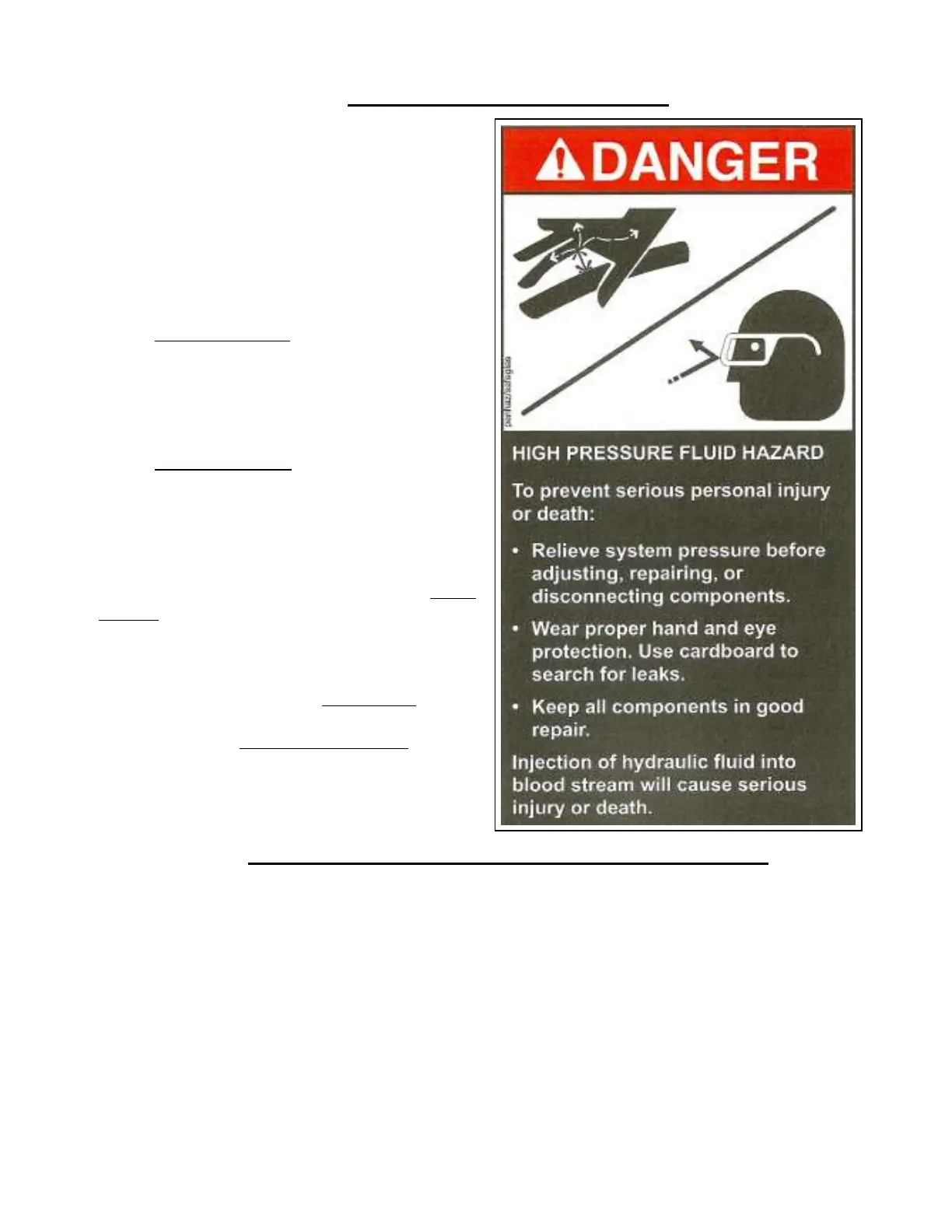

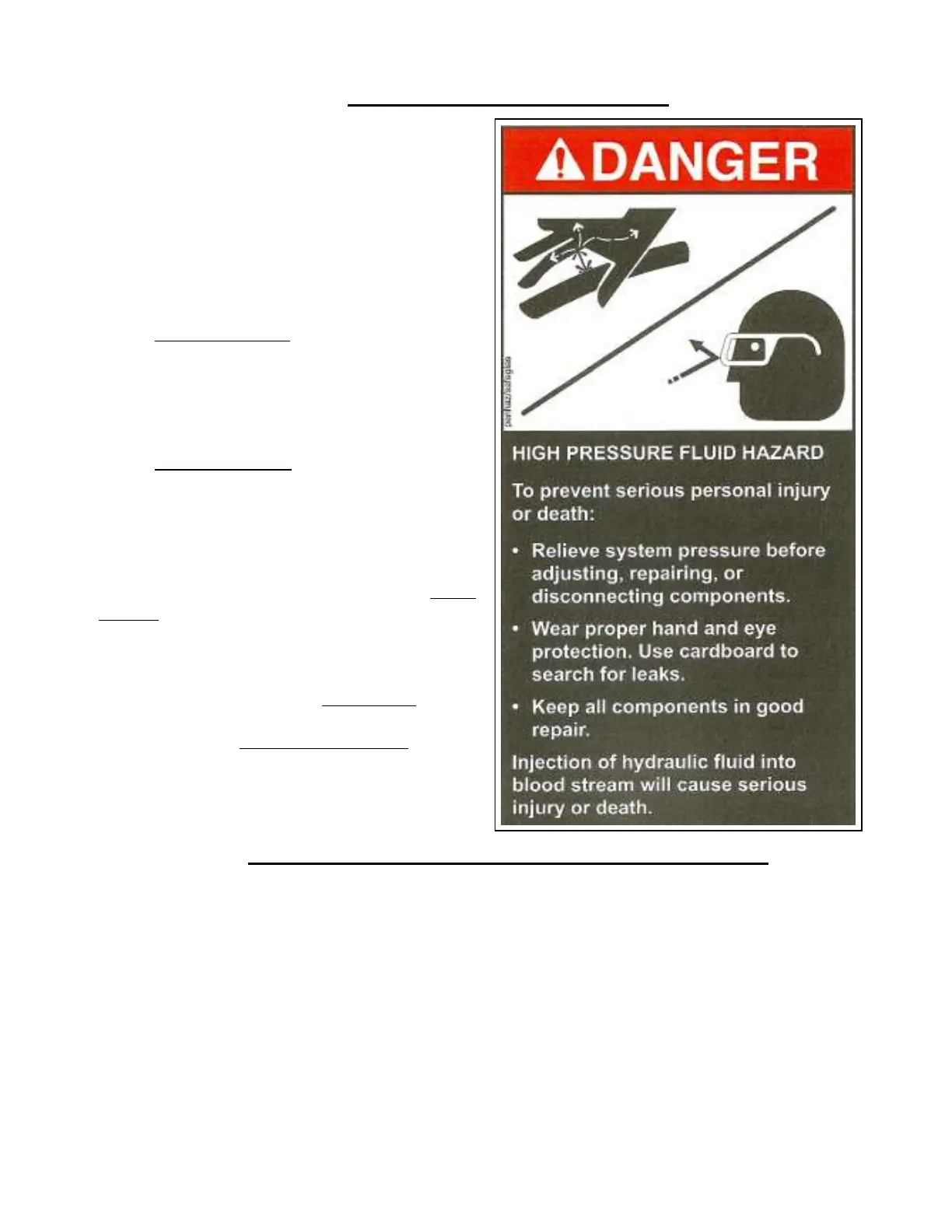

There are two safety pressure valves

located on each system. A Main Relief on the

control valve restricts the valve operating pressure

to 2600 psi. The Cylinder relief valves restricts

the cylinder operating pressure to 2800 psi and

protects the cylinders from extreme pressures that

could damage them.

6-2 STANDARD SPEED CYLINDER OPERATION

On our standard hydraulic system, to raise the lid we pump 32 gallons of oil into the bottom

of each cylinder. The 27 gallons of oil in the top goes back to the tank. The 5-gallon difference is

equal to the area of the rod.

To lower the lid we pump 27 gallons of oil into the top of each cylinder. The 32 gallons of oil

in the bottom goes back to the tank.

Loading...

Loading...