47

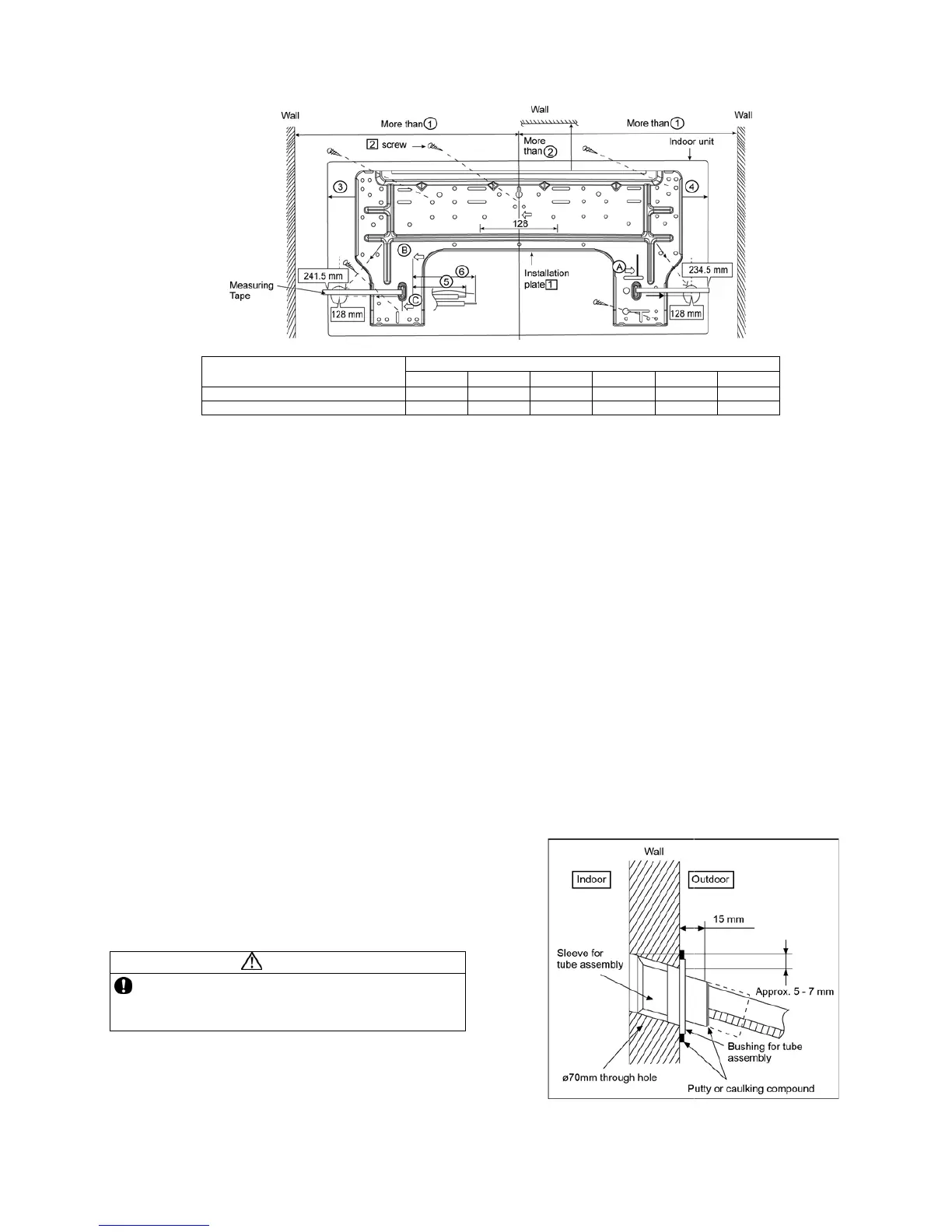

10.1.4 How to Fix Installation Plate

The mounting wall shall be strong and solid enough to prevent if from the vibration.

Dimension

Model

○

1

○

2

○

3

○

4

○

5

○

6

S9***, S12*** 485mm 82mm 165mm 158mm 93mm 145mm

S18***, S24*** 585mm 82mm 165mm 158mm 219mm 269mm

The centre of installation plate should be at more than

○

1 at right and left of the wall.

The distance from installation plate edge to ceiling should more than

○

2.

From installation plate left edge to unit’s left side is

○

3.

From installation plate right edge to unit’s right side is

○

4.

○

B : For left side piping, piping connection for liquid should be about

○

5 from this line.

: For left side piping, piping connection for gas should be about

○

6 from this line.

1 Mount the installation plate on the wall with 5 screws or more (at least 5 screws).

(If mounting the unit on the wall, consider using anchor bolts.)

o Always mount the installation plate horizontally by aligning the marking-off line with the thread and using

a level gauge.

2 Drill the piping plate hole with ø70mm hole-core drill.

o Line according to the left and right side of the installation plate. The meeting point of the extended line is

the center of the hole. Another method is by putting measuring tape at position as shown in the diagram

above. The hole center is obtained by measuring the distance namely 128mm for left and right hole

respectively.

o Drill the piping plate hole at either the right or the left and the hole should be slightly slanting to the

outdoor side.

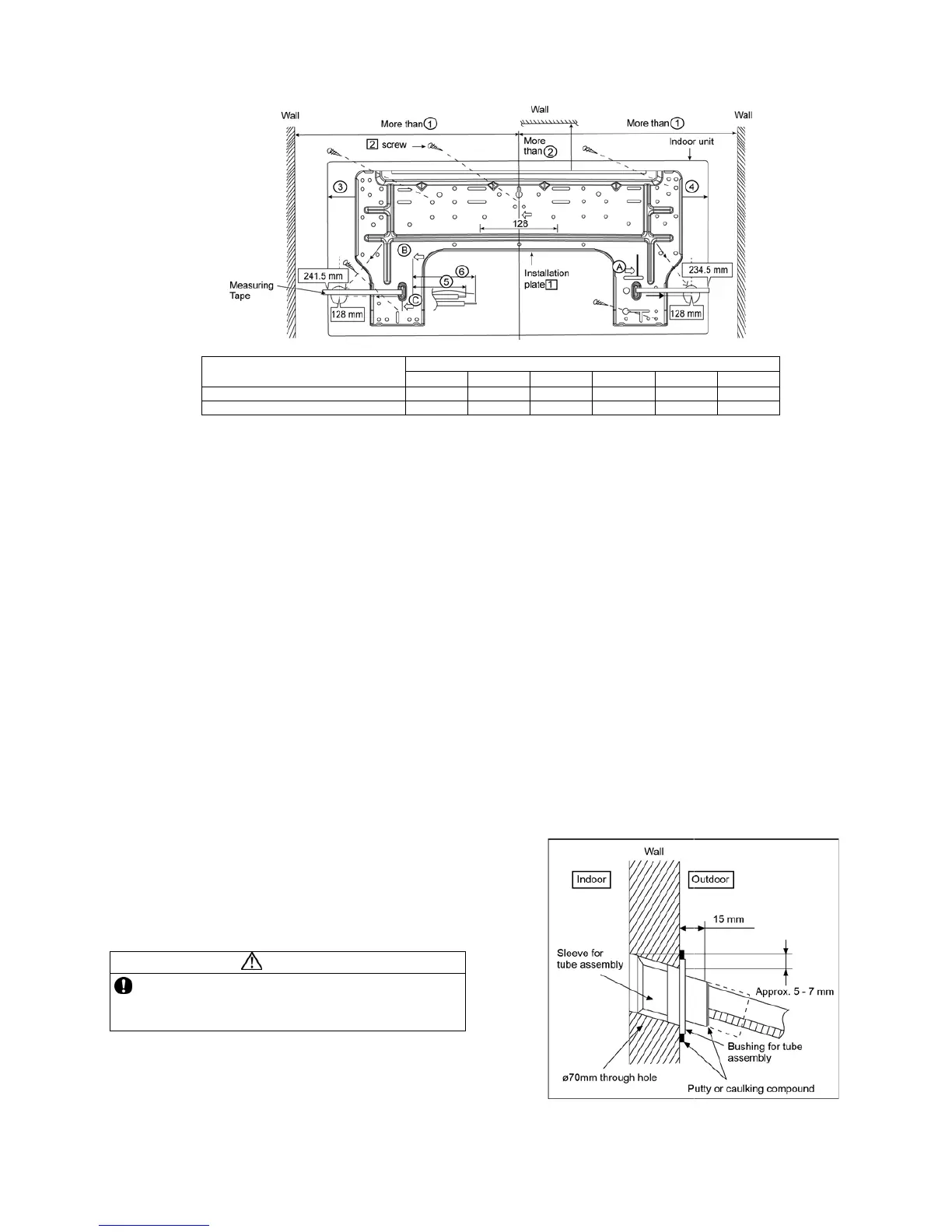

10.1.5 To Drill a Hole in the Wall and

Install a Sleeve of Piping

1 Insert the piping sleeve to the hole.

2 Fix the busing to the sleeve.

3 Cut the sleeve until it extrudes about 15mm

from the wall.

CAUTION

When the wall is hollow, please be sure to use the

sleeve for tube assembly to prevent dangers

caused by mice biting the connection cable.

4 Finish by sealing the sleeve with putty or

caulking compound at the final stage.

Loading...

Loading...