12

Parker Autoclave Engineers

Instrumentation Products Division

Erie, PA USA

www.autoclave.com | Cat. 02-9221ME

Section 7.0

Recommended Spare Parts

Recommended parts and tooling for all variations of Coning and Threading Machine Models AEGCTM-2 and AEGCTM-2E.

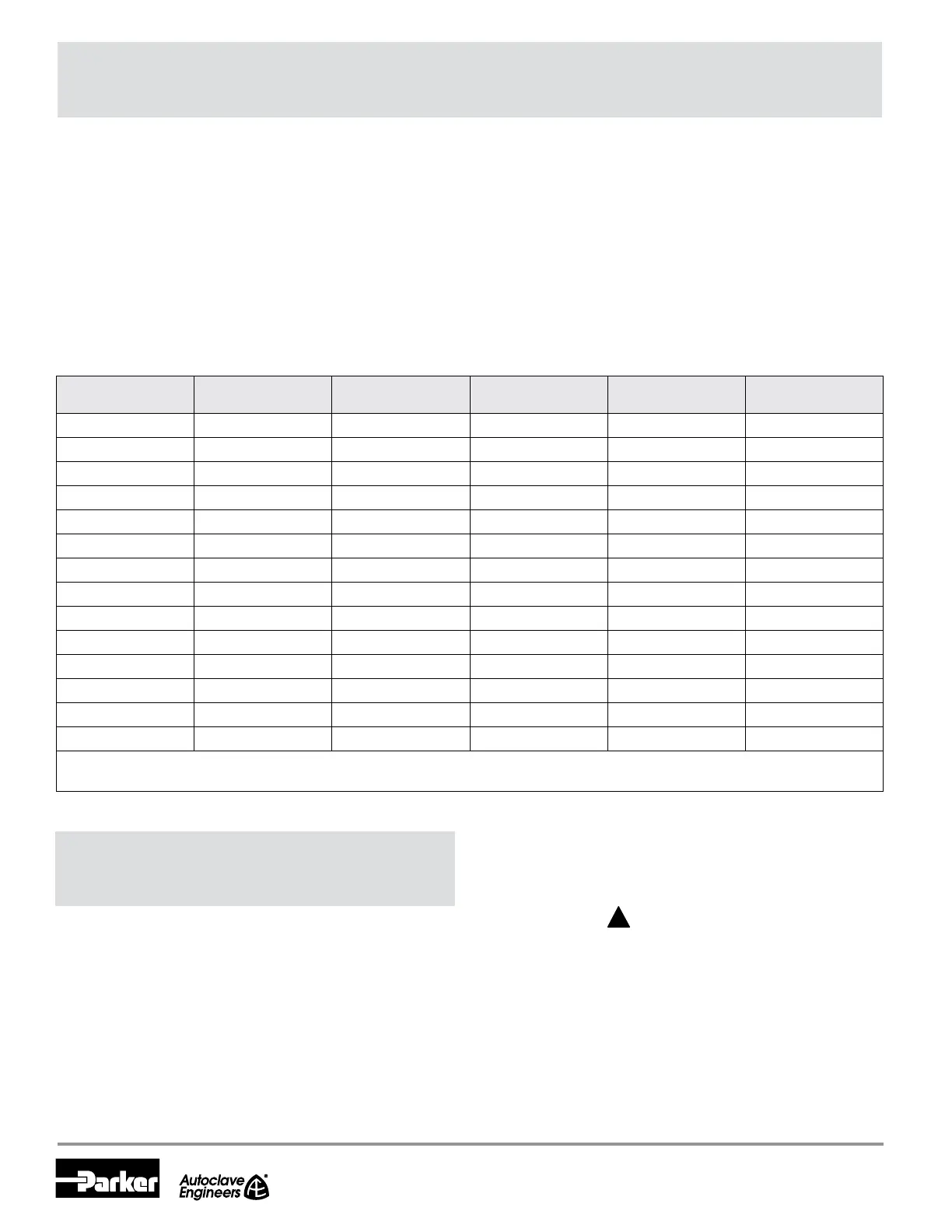

Table 5

Tooling Part Numbers

Tube Size

OD x ID (in)

Collet (single) Collets (set of 3)

Cutting Blades

(set of 2)

Die Chaser

(set of 4)

Tooling Kit*

1/4 x .109 CTM4C-S CTM4C-2 CTM4BX AEGCTM4D AEGCTM4X-2

1/4 x .083 CTM4C-S CTM4C-2 CTM4B AEGCTM4D AEGCTM4-2

5/16 x .062 CTM5C-S CTM5C-2 CTM5B AEGCTM6D AEGCTM6X-2

3/8 x .203 CTM6C-S CTM6C-2 CTM6BX AEGCTM6D AEGCTM6X-2

3/8 x .125 CTM6C-S CTM6C-2 CTM6B AEGCTM6D AEGCTM6-2

9/16 x .359 CTM9C-S CTM9C-2 CTM9BXX AEGCTM9D AEGCTM9XX-2

9/16 x .312 CTM9C-S CTM9C-2 CTM9BX AEGCTM9D AEGCTM9X-2

9/16 x .250 CTM9C-S CTM9C-2 CTM9B40 AEGCTM9D AEGCTM940-2

9/16 x .188 CTM9C-S CTM9C-2 CTM9B AEGCTM9D AEGCTM9-2

3/4 x .516 CTM12C-S CTM12C-2 CTM12BX AEGCTM12D AEGCTM12X-2

3/4 x .438 CTM12C-S CTM12C-2 CTM12B AEGCTM12D AEGCTM12-2

1 x .688 CTM16C-S CTM16C-2 CTM16BX AEGCTM16D AEGCTM16X-2

1 x .562 CTM16C-S CTM16C-2 CTM16B AEGCTM16D AEGCTM16-2

1 x .438 CTM16C-S CTM16C-2 CTM16BXX AEGCTM16D AEGCTM16XX-2

*Tooling Kit includes 3 collets, a set of 2 cutting blades and a set of 4 die chasers.

Note: See the Drawings and Schematic section for information on additional parts not required as spare parts.

7.1 Drive Belt: for the AEGCTM-2E-CE, p/n P-6958-1

for the AEGCTM-2, p/n P-1754-2

7.2 Coning Blade Holder, p/n 201D-0159

7.3 Coning & Threading DVD, p/n P-9930-D

7.4 Coning & Threading Gage

7.5 Other Tooling: See Table 5.

7.6 Cutting Oil, p/n P-8699

Section 8.0

Service

For service, contact the Parker Autoclave Engineers

Representative in

your area or contact the Parker Autoclave Engineers Customer

Support Services at 800-458-0409 or by fax at 814-860-5811.

Little Giant

®

Pump Instructions

IMPORTANT - Read carefully for better service and longer life.

The pump which you have just purchased is of the highest qual-

ity workmanship and material. It has been engineered to give you

long and trouble-free service.

Like any other piece of mechanical equipment, a little attention

will help to keep it in perfect operating condition for a long time.

Pump Information and Suggestions

1. SYMBOL OF . DO NOT CONNECT THIS UNIT TO

VOLTAGE OTHER THAN THAT SHOWN ON THIS UNIT.

IF YOU ARE IN DOUBT, PLEASE HAVE YOUR SERVICE-

MAN CHECK. THE WARRANTY DOES NOT COVER UNITS

BURNED OUT BY HIGH VOLTAGE CURRENT.

2. DO NOT LET THE UNIT OPERATE DRY.

The pump is cooled by the ow of liquid through the

pump. Running the pump dry may damage the seals

or motor.

3. The pump must be submerged when it is operating.

The intake volute must always be below the liquid level.

Loading...

Loading...