6

Parker Autoclave Engineers

Instrumentation Products Division

Erie, PA USA

www.autoclave.com | Cat. 02-9221ME

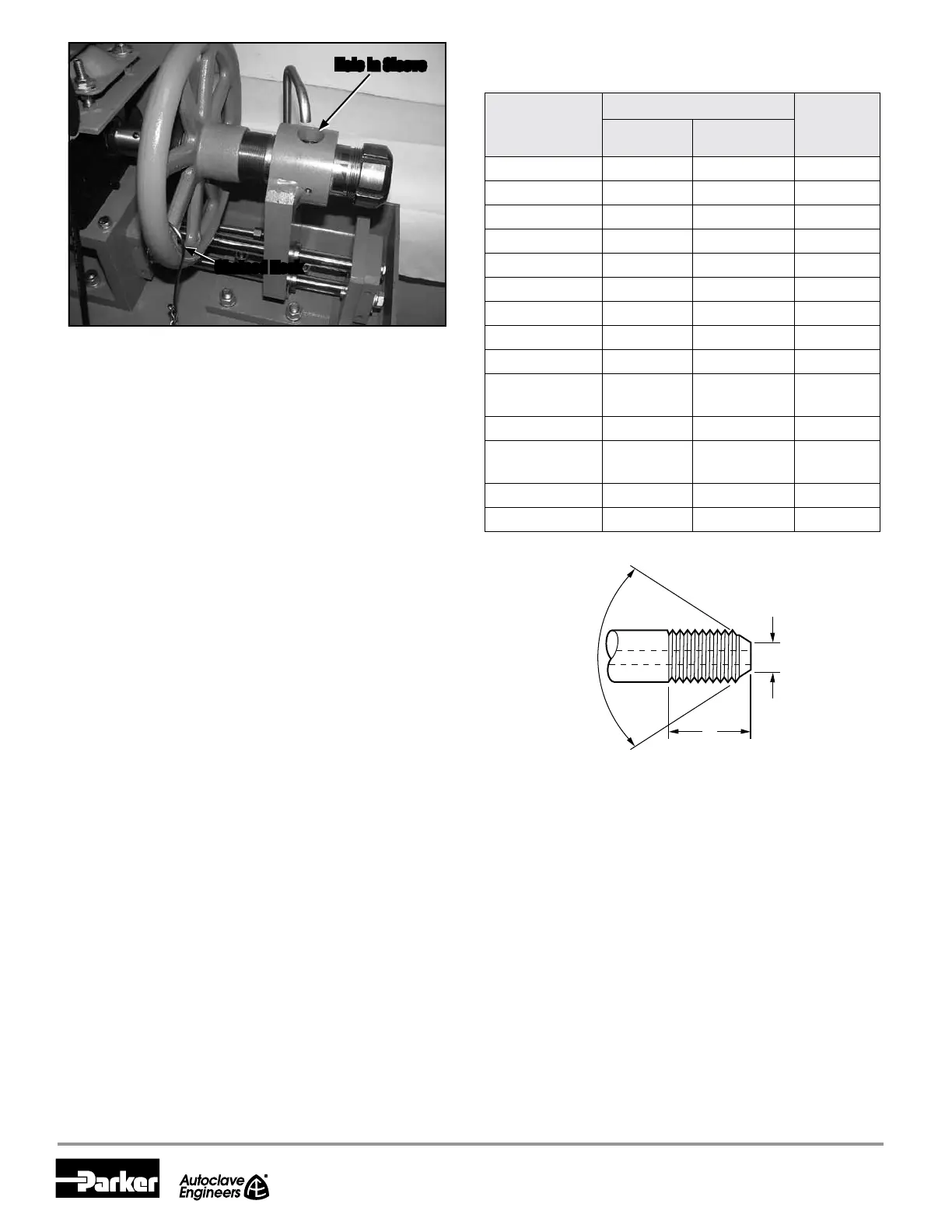

4.18 Rotate feedwheel until you see the cutting blades extend

approximately 1/4" through the hole in the sleeve see

Figure 6.

4.19 With the machine turned off and the power cord un-

plugged, insert tubing through the collet until it is ush

against the blades. Now back tubing up about 1/4" and

tighten the collet nut with the spanner wrench.

4.20 Connect the power cord and start the machine. Advance

the blades by turning the feedwheel (ccw) slowly. When

the blades start to cut (as seen through hole in sleeve),

rotate feedwheel the number of turns indicated in

Table 2. Each turn of the feedwheel advances the tube

1/16". Advance cutting blades slowly.

Note: 304 SS tubing will require a slower blade feed rate

than 316 SS. The rate of turning the feedwheel for

304 SS is approximately 1/4 that of 316 SS.

4.21 At completion of indicated number of turns, hold feed

wheel stationary for three to ve (3-5) revolutions of the

cutting blades. This squares and nishes the coned end

of the tubing.

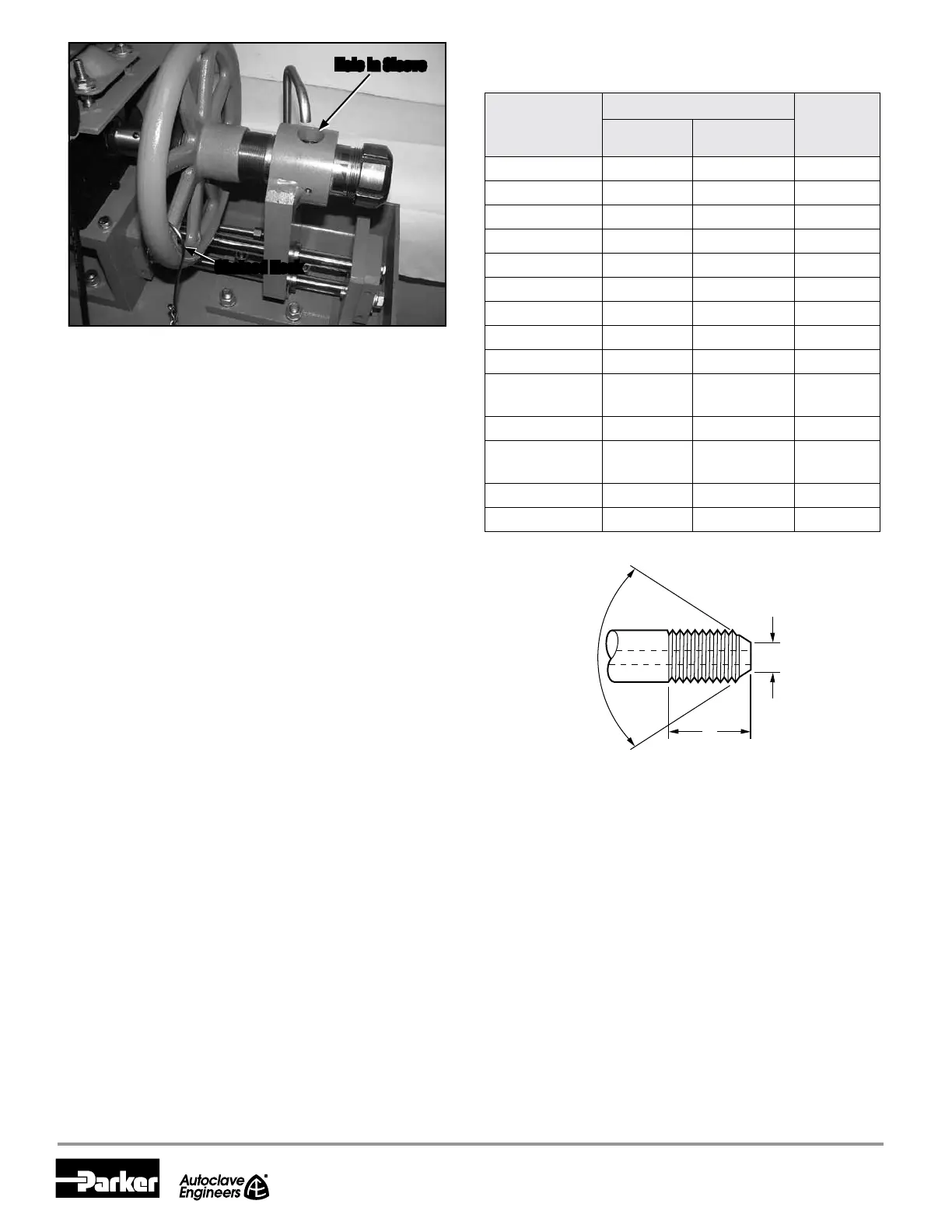

Note: To ensure a proper sealing of a coned connection,

it is necessary that the nished cone has a square end

which is perpendicular to the center line of the tubing.

The critical nish for coned connections is on the leading

edge of the cone. The transition point where the cone

meets the square end of the tube must be free of burrs

and tool marks (Figure 7).

4.22 Reverse the feedwheel until the tubing is disengaged

from the cutting blades. Attach the chained hook to the

feedwheel and if no one is using the threading end of the

machine, turn it off.

Hole in Sleeve

Chained Hook

Figure 6

Illustration of Coning Operation

Table 2

Required Feedwheel Rotation for Coning Operation

Type of Connection

Tube Diameters

Number of

Feedwheel

Turns

OD

in (mm)

ID

in (mm)

SM250CX20 1/4 (6.4) .109 (2.8) 2.0

SM375CX20 3/8 (7.1) .209 (5.2) 2.0

SM562CX20 9/16 (14.3) .312 (7.9) 2.5

SM562CX10 9/16 (14.3) .359 (9.1) 2.0

SM750CX20 3/4 (19.1) .438 (11.1) 3.0

SM750CX10 3/4 (19.1) .516 (13.1) 2.5

SM1000CX30 1 (25.4) .438 (11.1) 6.0

SM1000CX20 1 (25.4) .562 (14.3) 4.0

SM1000CX10 1 (25.4) 688 (17.5) 3.0

M250C

100M250C

1/4 (6.4) .083 (2.1) 2.0

M312C150 5/16 (7.9) 062 (1.6) 3.0

M375C

100M375C

3/8 (7.1) .125 (3.2) 2.5

M562C 9/16 (14.3) .188 (4.8) 4.0

M562C40 9/16 (14.3) .250 (6.4) 3.5

59°

+0°

–2°

D

L

Figure 7

Tube End Dimensions (see Table 3)

4.23 Use the spanner wrench to loosen collet nut, releasing

tube from collet.

4.24 Remove tubing and inspect cone. There should be no

score marks on the tube and it should be completely

faced.

4.25 Deburr the inside of the tube. This completes the coning

operation.

Loading...

Loading...