5

Parker Autoclave Engineers

Instrumentation Products Division

Erie, PA USA

www.autoclave.com | Cat. 02-9309ME

The pumps unique design allows for self priming. To prime,

regulate the air pressure to between 15 psi (1 bar) or lower or

use an air ow regulator to reduce to a slow stroke frequency.

With the high pressure side connected to a vented system, allow

the pump to cycle until a consistent ow of liquid is achieved.

Let the pump ow freely to purge any air in the liquid system.

Loosening the outlet gland or pipe can also assist in priming the

pump.

Increase the air pressure using the air pressure regulator until

you achieve your desired output liquid pressure. At this point

the pump will stall. You can calculate the output pressure by

multiplying the input air supply by the actual pressure ratio of

the pump. The pump will automatically restart if there is a drop

in downstream high pressure.

Section 8.0

Process Media

Parker Autoclave Engineers pumps discussed in this manual are

used for pumping oil, water and oil/water mixtures. Special seals

are also available for chemical service. Please contact Parker

Autoclave Engineers to discuss availability of special seals.

Verify liquid pressure system is protected with

an over pressure relief device.

WARNING

Use an air pressure regulator to assure maximum air

drive pressure listed on the pump label is not

exceeded. An air pressure regulator must also be used to

assure the pump will not exceed maximum liquid output

pressure listed on the pump label.

WARNING

The pump and high pressure liquid system must be

vented prior to installation and start-up.

WARNING

DO NOT exceed the maximum liquid pressure and tem-

perature rating specied on the assembly drawing and

label for your pump. It is recommended to use a liquid

relief valve or rupture disk to prevent over

pressurization of your high pressure system.

DO NOT exceed the maximum air drive pressure listed on

your pump label.

WARNING

Be sure to securely tighten high

pressure tube, pipe or gland with the appropriate torque

after the priming has been achieved.

Reference Tools, Installation, Operation and

Maintenance Manual for tube gland torque value.

WARNING

While testing has shown o-rings to provide satisfactory

service life, actual life will vary widely with differing

service conditions, properties of reactants, pressure and

temperature cycling and age of the o-ring.

FREQUENT INSPECTIONS SHOULD BE MADE

to detect any deterioration and o-rings replaced

as required.

WARNING

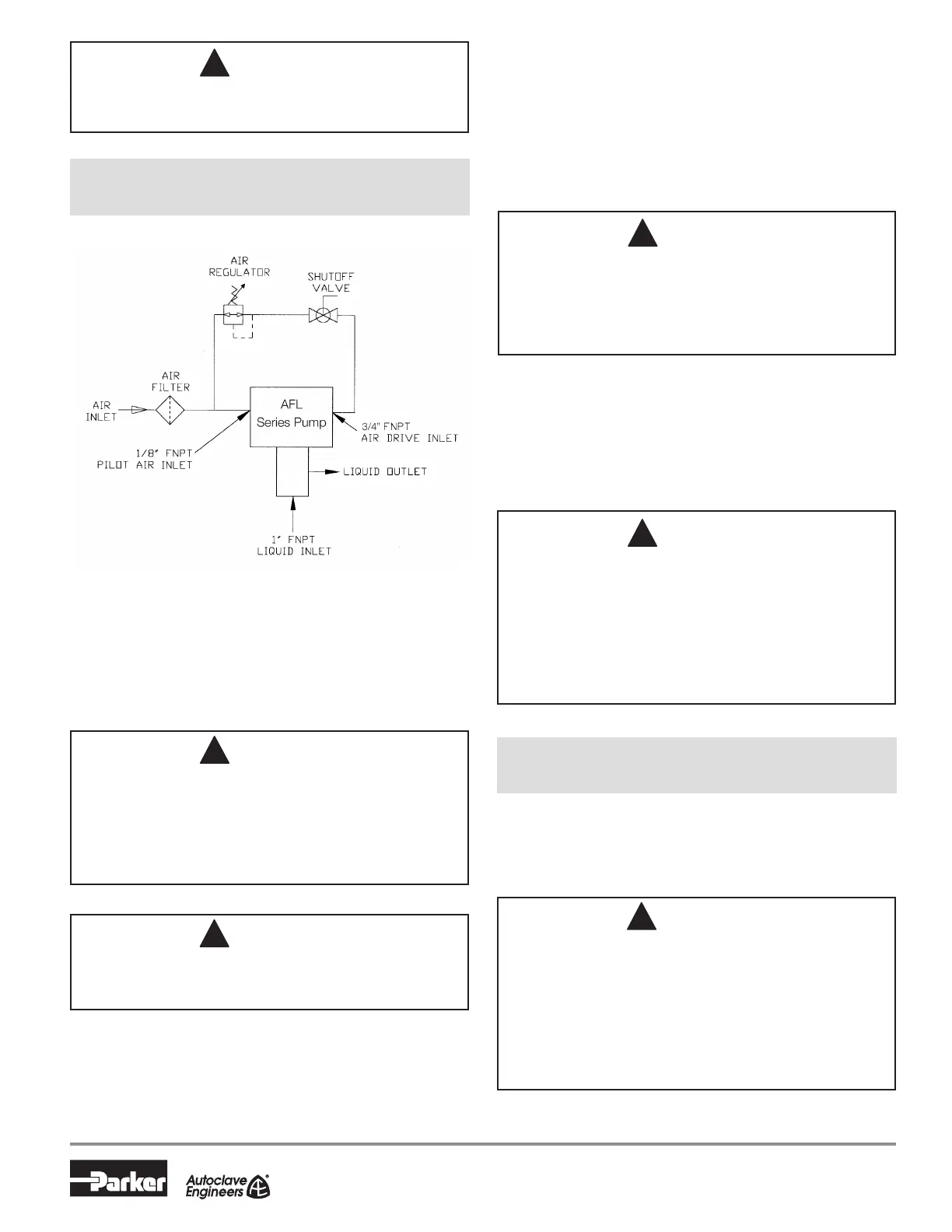

Section 7.0

Pump Start-Up

Fig. 7.0 Air Line Schematic

As shown above, a ltered main air supply line is required. The

ltered air supply will go to a pressure regulator which can be

set to achieve the desired output liquid pressure according to the

pressure ratio of the pump.

Loading...

Loading...