D1VW_EE 5715-690 UK.indd 11.07.22

Directional Control Valve

Series D1VW Explosion Proof

Operating Instructions

11

Parker Hannin Corporation

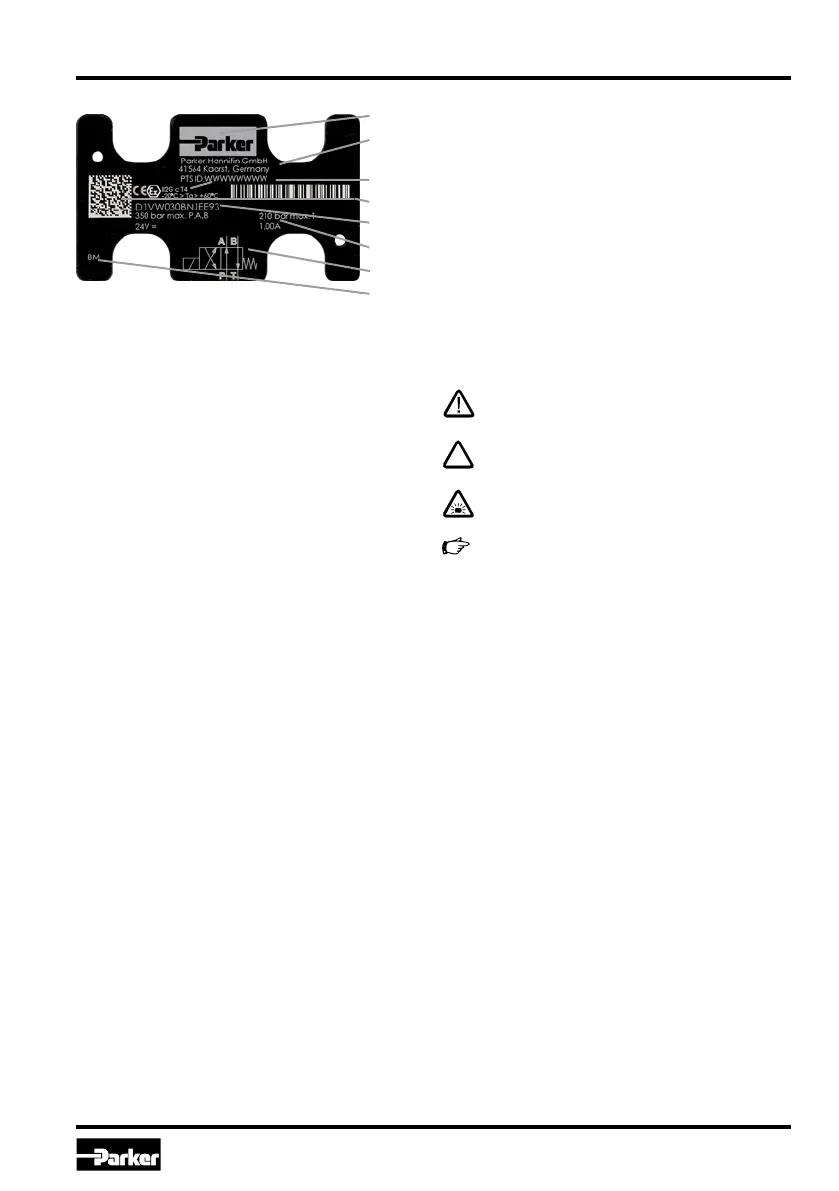

Name plate

Manufacturer's logo and address

CE mark, Ex protection symbol and explosion protection class

of the complete valve to European Directive 2014/34/EU

Serial number (PTS ID: eight-digit number, barcode)

QR-code (internal use)

Entire name of the complete valve

Hydraulic and electrical data

Hydraulic symbol

Code for year and month of manufacture

Symbols

These instructions use symbols that must be noted

according to their importance:

Notes relating to the warranty

Notes relating to potential damage to the

valve or connected system components

Notes relating to potential hazards

Useful additional information

Marking, name plates

Information attached directly to the valve such as

circuit plans and name plates must be observed

and kept in a legible state.

Work on the valve

Work relating to the installation, commissioning,

maintenance and repair of the valve may only be

carried out by qualied persons. Qualied persons

are dened as persons who, on the basis of edu-

cation, experience and instruction, have sucient

knowledge of applicable requirements and ac-

cepted rules of the technology.

Throughout any installation, commissioning, main-

tenance and repair work, it is the responsibility of

the operator to ensure that there is no risk of ex-

plosion.

Before starting such work, the operator has to

ensure that tools and equipment are only used if

they do not damage the valve and they do not

leave behind residues that are inammable.

In addition, clean the valve before starting such work,

in particular removing dust, liquids and other depo-

sits. Cleaning should be done using a lint-free cloth.

Tools may not be used if they might cause a static

charge on use.

2. Safety instructions

Read the operating instructions thoroughly before

installation, commissioning, maintenance, repair and

storage, and observe them. Failure to observe the

operating instructions may result in damage to the

valve or the parts of the system connected to it.

In particular, in the case of explosive atmospheres,

any failure to observe the operating instructions

may result in an explosion.

The system operator must make these operating

instructions visible and easily accessible to opera-

ting and maintenance personnel.

Compliance with applicable standards/legal requi-

rements must be enforced. This particularly applies

to plant safety and environmental protection.

A list of such standards, etc. appears in the annex

by way of example.

Before starting commissioning, installation, main-

tenance and repair work, the hydraulic system must

be depressurised and power must be disconnected

from the electrical installation.

In addition, the electrical installation must be secured

so that power cannot be restored unexpectedly.

The valve may become hot during operation. To

avoid risk of burns, do not touch the valve surface.

The system operator must monitor the temperature

and cool the oil if necessary in order to the keep

within the maximum temperatures set out in these

operating instructions (see technical data). In this

connection, observe the relevant directions in the

operating instructions of the supplier (solenoid

system).

Any leaks occurring at the valve must be rectied

immediately.

Loading...

Loading...