18 GB

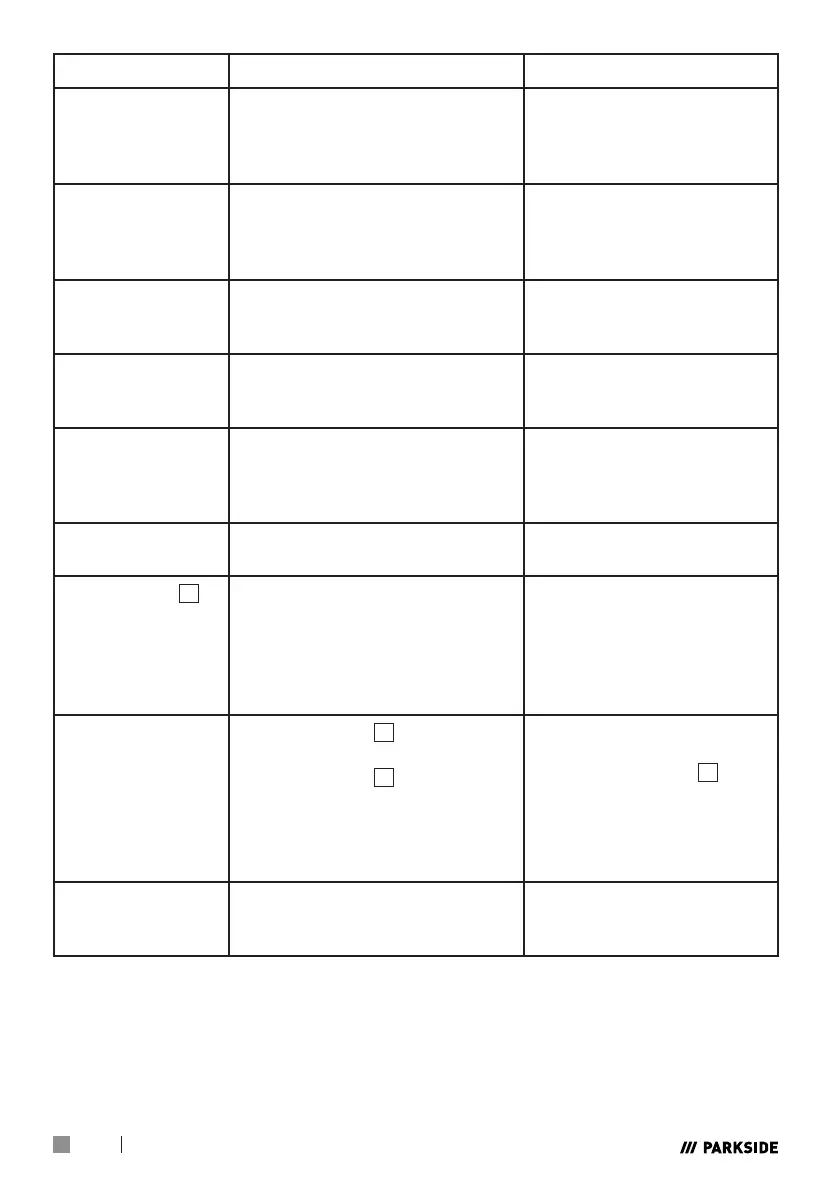

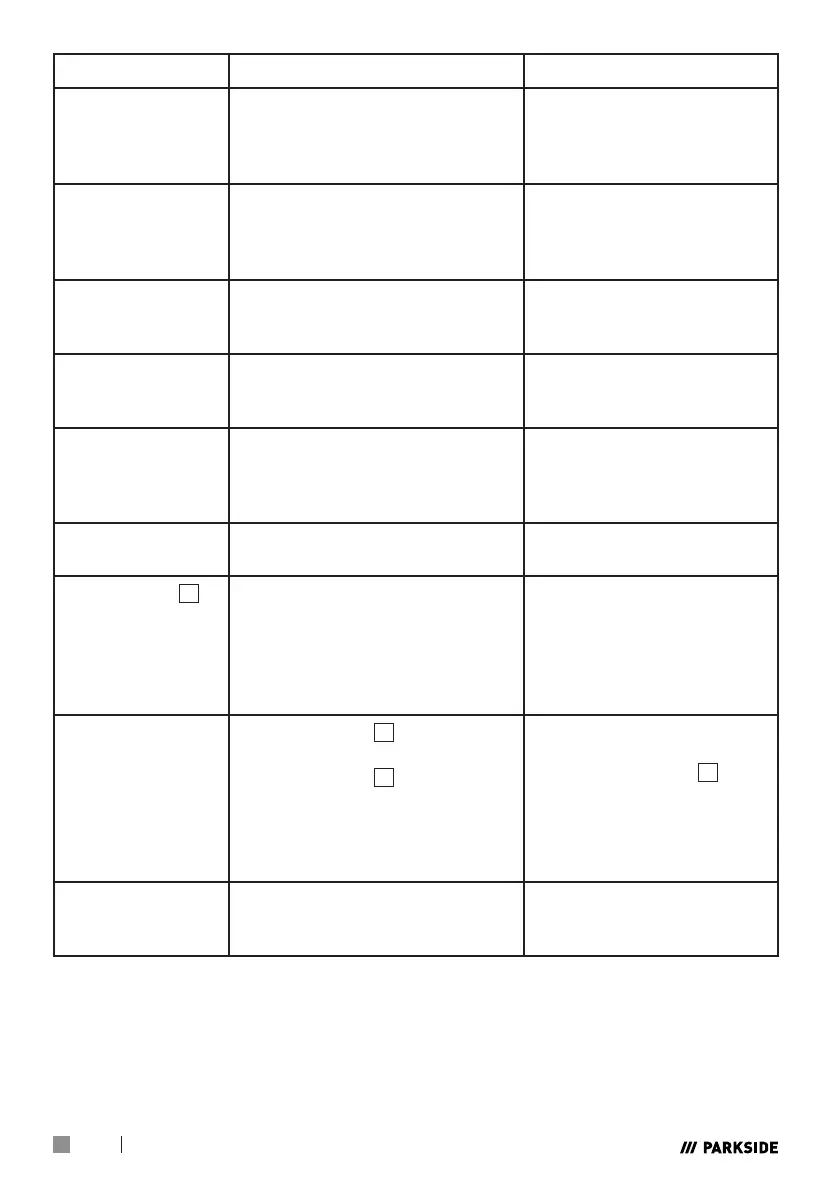

Faults Cause of fault Troubleshooting

Warning lamp

switches on?

Overheating protection

switched on.

Input voltage too high.

Allow device to cool

down.

Input voltage according to

type plate.

No output current?

Machine faulty.

Overvoltage protection

activated.

Machine must be

repaired.

Allow device to cool

down.

Output current does

not decrease?

Input voltage too low.

Connection cable cross-section

too small.

Observe input voltage

according to type plate.

Air flow cannot be

regulated?

Compressed air hose damaged

or faulty.

Valve/manometer fails.

New connection of the

line.

HF-arc is not

created?

The burner switch is faulty.

Soldering point on the burner

switch or plug loosened.

Valve/manometer fails.

Replace electrode.

Bad ignition?

Burner wear parts damaged or

worn.

Change wear parts.

Plasma burner

8

is

not ready for

operation?

Current switch is switched off.

Air transmission is restricted.

Workpiece is not connected to

the earthing terminal.

Switch the current switch

to “on”.

Another indication of this

is a green flame. Check

the air supply.

Check the connections.

Sparks fly upwards,

instead of down

through the

material?

Burner sleeve

8c

does not

penetrate the material.

Burner sleeve

8c

is too far

away from the material.

Material was probably not

earthed properly.

Lifting speed is too quick.

Increase the current.

Reduce the gap between

the burner sleeve

8c

and

material.

Check the connection for

correct earthing.

Reduce the speed.

Initial cut but not

completely drilled

through?

Potential connection problem. Check all connections.

Loading...

Loading...