6

3.0 Technical Specicaons

XTI-201 AC/DC

Input voltage 230V +/- 10%

Frequency 50/60Hz

Input current

20A max

15 e

Fuse rang 16A

Output OCV 66

Output load

voltage

10-26V

Output Current 10-200A DC

Control Plug wiring

The link between pins 1 and 2 should only be ed if

you are using a remote current control. Wire colours

shown refer to the Parweld ERGO TIG torch wiring.

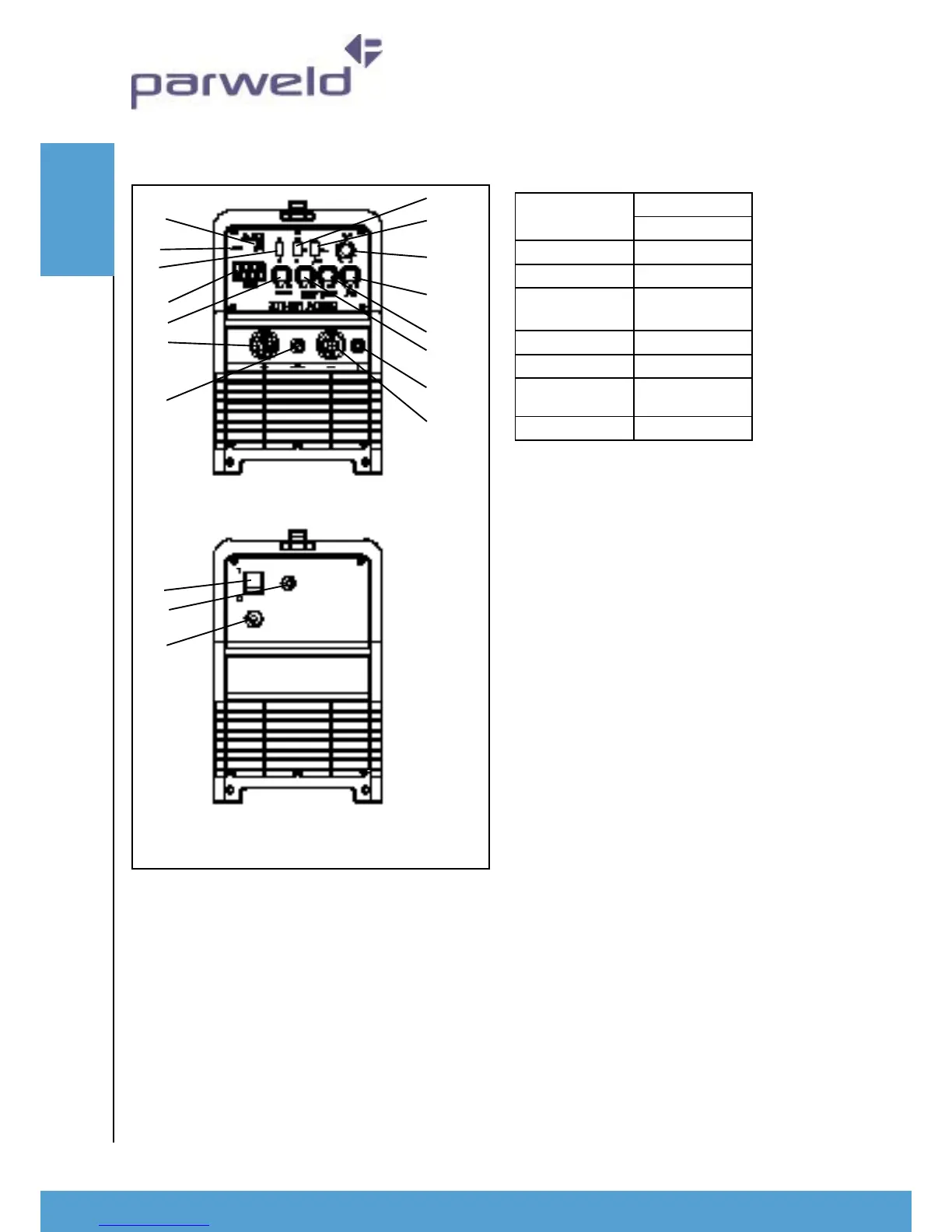

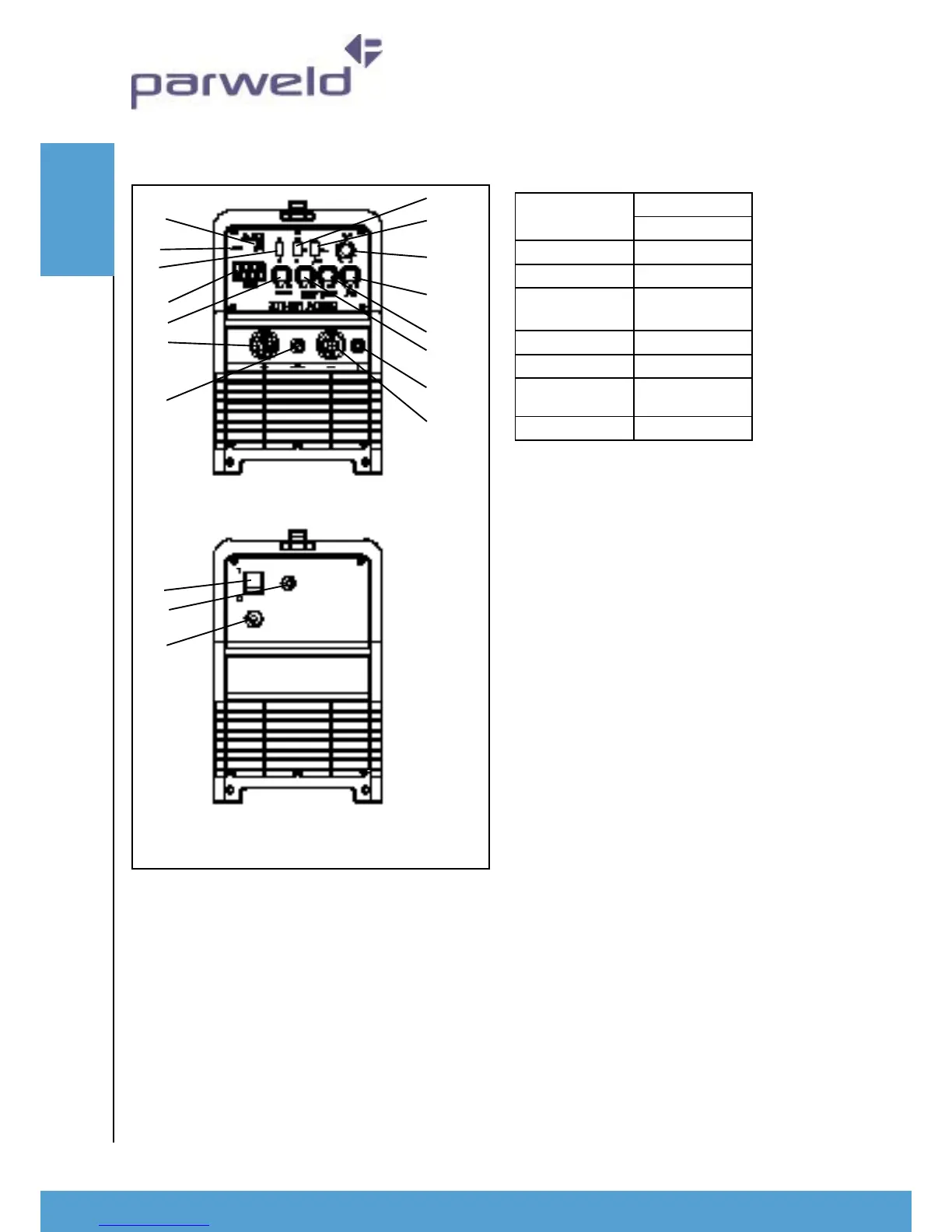

4.0 Descripon of Controls

1) ON OFF Switch for switching on or o the mains

supply to the machine. Note the output of the

machine is permanently on in MMA mode unless the

on/o switch is in the o posion.

2) Fault light This indicates a fault or over temperature

condion with the machine refer to the fault nding

secon for further informaon

3) Power light This indicates mains power is applied

to the machine and that the machine is currently

switched on when the light is illuminated

4) TIG mode, this toggles between LIFT-ARC mode and

HF start TIG.

5) Process selector. This switch has 3 posions the top

posion selects MMA welding and will latch on the

output when in this posion. The centre posion is

TIG welding with 2 touch trigger control (momentary).

The boom posion is TIG welding with 4 touch

control (latching)

6) Output power switch. This switch has 3 posions

the top posion selects DC output in TIG or MMA

mode. The centre posion selects AC output in MMA

or TIG mode and the boom posion allows a gas test

or purge to be performed when TIG welding.

7) Cleaning Control. This control allows the balance

of the AC wave to be altered so increasing or reducing

the cleaning eect when AC TIG welding.

8) Post Gas, this allows control of the post gas ow at

the end of a weld when in TIG mode. It is adjustable

from 3 to 10 seconds.

9) Downslope/Arc force. This control is dual funcon

in TIG mode it controls the downslope me for the

welding current aer the trigger is released from 0 to

10 seconds.

In MMA mode it allows adjustment of the welding Arc

2.0 Product Descripon

This welding machine is manufactured using advanced

inverter technology. The input voltage is reced to

DC and then inverted

to high frequency AC voltage. before being converted

back to DC for the output .This allows the use of a

much smaller transformer and so allowing weight

saving and improved power eciency.

1

16

17

6

7

8

9

10

11

14

3

5

2

4

11

12

13

15

CONTROLS

Loading...

Loading...