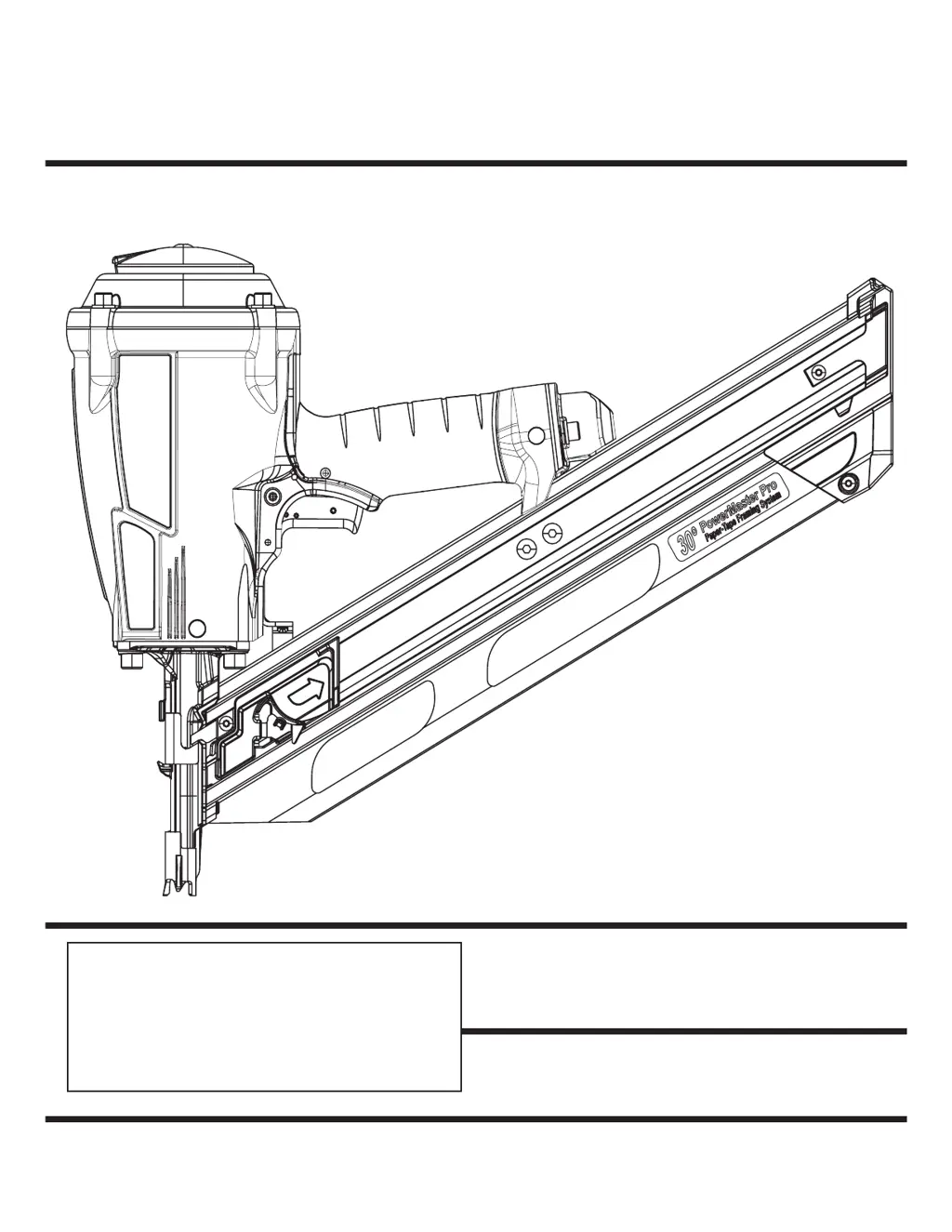

How to fix Paslode PowerMaster Pro F-350P when fasteners won't drive completely into wood?

- CCharles GriffinJul 27, 2025

If your Paslode Nail Gun is not driving fasteners completely into the wood, you can adjust the work contacting element (retract length) and increase the air pressure, but do not exceed 120 psi.