High Purity Nitrogen Generator

UM – NM20ZA – Rev 13

Principle of Operation

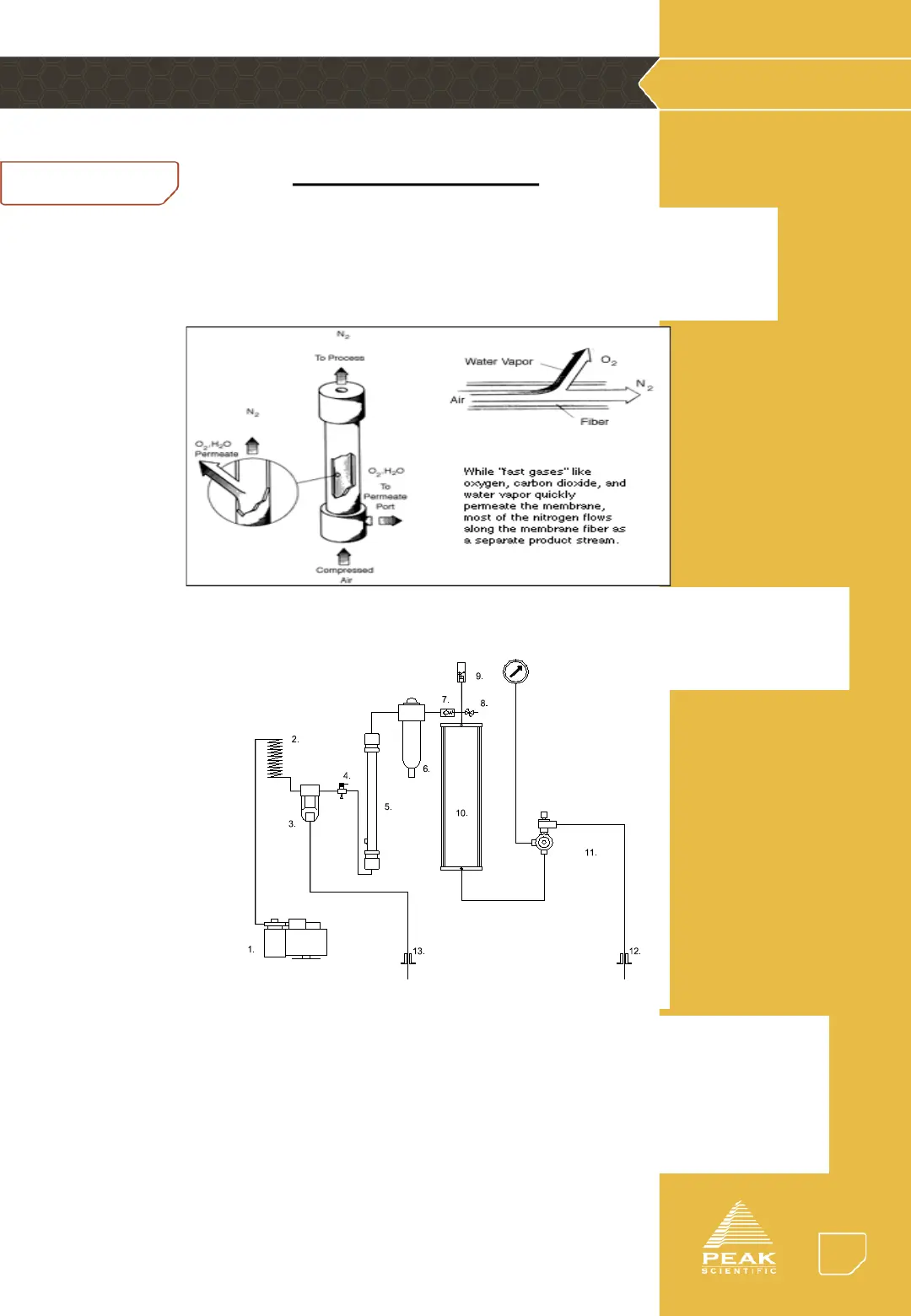

Peak Scientific Instruments NM20ZA Generators utilize two different types of air

preparation membranes to produce the required Gas outputs. The Nitrogen side of the

generator employs “Hollow Fiber Membrane” Technology to efficiently separate

Nitrogen from other gases present in ambient air. An overview of this process can be

seen below.

The Zero Air side of the generator uses the latest technology in membrane dryers to produce a clean dry supply of

Zero grade air. Both membranes are mounted in a similar fashion in the generator and utilize standard ancillary

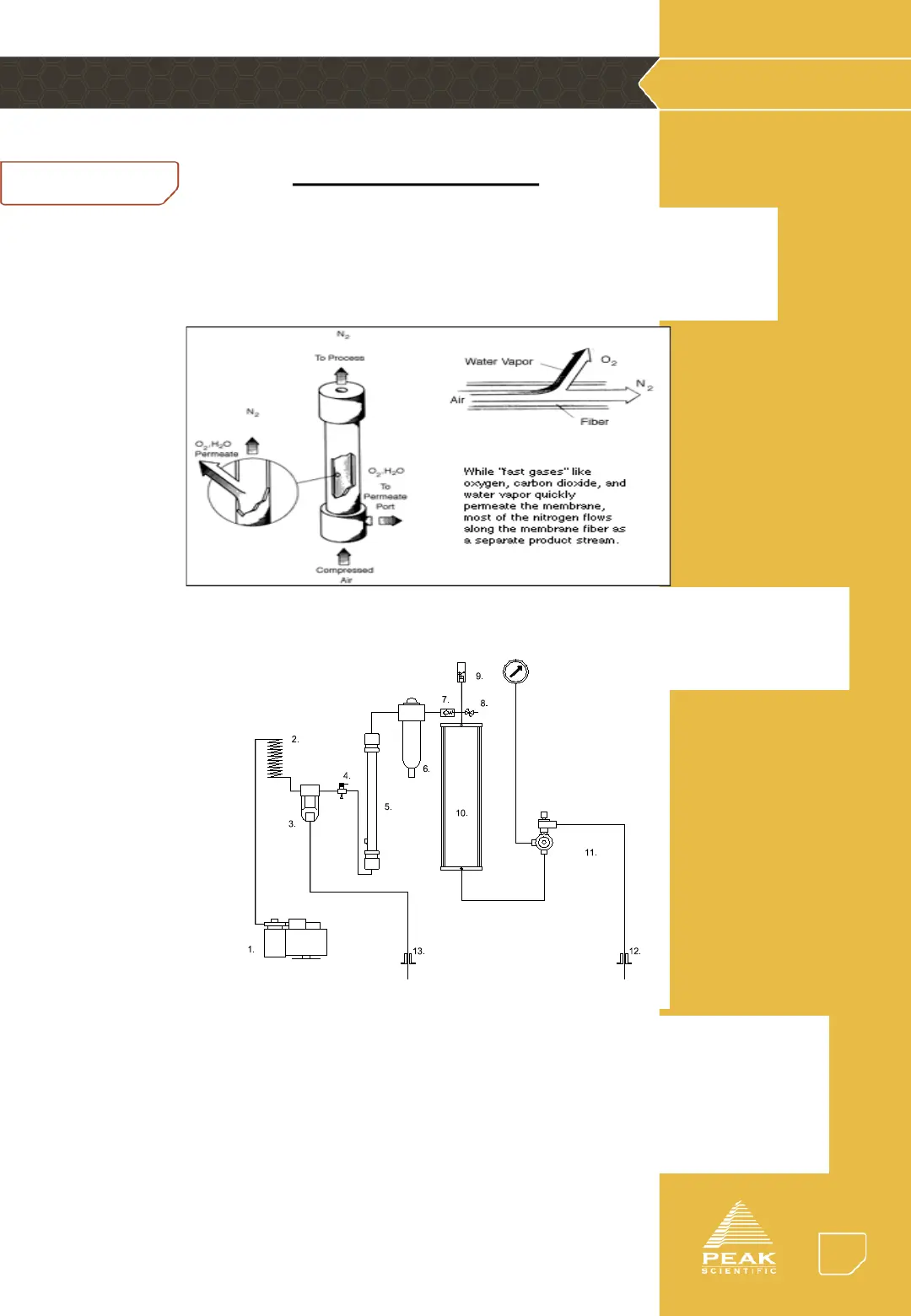

components to maximize the interchangeability of the systems. The standard membrane diagram can be seen

below.

Membrane - Standard Diagram

Air is drawn into the system by the Compressor (1) and passed through the Cooling Coil (2) and the AFD –

3000 Micro Mist Filter (3) into the Membrane (5). After the Membrane (5) the gas is passed through a

Reverse Acting Carbon Filter (6) to remove any remaining impurities and via the Non-Return Valve (Check

Valve) (7) into the Receiver (10). The stored gas is regulated (11) to give the required output pressure and

flow. Receiver pressure is measured (9) to allow the generator to un-load (4) and shut-down should

demand cease. A Safety Relief Valve (8) is fitted to protect the system against over pressure. Gas is

delivered out of the machine via the Outlet Port (12). Any moisture collected by the AFD – 3000 Micro Mist

Filter (3) is expelled via the Drain Port (13).

Principle of Operation

14

Loading...

Loading...