13

C. VENT PIPING & CHIMNEY

1. Inspect the existing chimney or vent system. Make

sure it is in good condition. Inspect chimney liner

and repair or replace if necessary.

2. The vent system and installation must be in

accordance with Venting of Equipment chapter of

the current edition of the National Fuel Gas Code,

ANSI Z223.1/NFPA 54, sections 7.2, 7.3 or 7.4

of CAN/CSA B149.1, Natural Gas and Propane

Installation Code, or applicable provisions of the

local building codes.

3. Chimney/Vent Operation: The vent system must be

sized and installed to provide the draft needed to

remove all combustion products. If the vent system

does not provide enough draft, combustion products

will spill into the building from the draft hood

relief opening. If spillage of combustion products

occurs, check the vent system, the combustion and

ventilation openings and make sure the boiler room

is never under negative pressure.

4. Chimney flue gas condensation is affected by a

number of factors such as chimney design, flue

connector length, common venting, and flue gas

temperature. If your application experiences flue

gas condensation, installation of a listed corrosion

resistant metal liner is required.

5. Inspect the existing chimney and lining for structural

soundness, corrosion and perforations.

6. Do not alter boiler draft hood or place any

obstruction or non-listed damper in the vent system.

7. Install vent pipe to slope upward at least 1/4” per

lineal foot (21 mm per meter) between the draft

hood outlet and the chimney.

Installer le tuyau d’évent avec une pente ascendante

minimum de 21 mm au mètre (1/4 po au pied) à la

sortie du coupe-tirage et la cheminée.

8. Before connection of joints, inspect the vent pipe

interior for foreign objects such as tools, equipment,

rags, etc. and remove if present.

9. Insert vent pipe into but not beyond the inside wall

of the chimney flue.

10. Do not connect vent connectors serving appliances

vented by natural draft into any portion of mechanical

draft systems operating under positive pressure.

11. Support horizontal portions of the venting system

to prevent sagging by use of metal strapping or

equivalent means. Locate supports at no more than

4 foot (1.2 meter) intervals.

Fournir un support à toute portion horizontale du

système d’évacuation à l’aide de courroies de métal

ou une méthode équivalente afin de l’empêcher de

s’affaisser. Placer les supports à des intervalles ne

dépassant pas cent vingt deux (122) centimètres

(4 po), ou en suivant les recommandations d’

installation du fabricant.

12. Secure all joints including flue collar, draft hood,

vent damper, using sheet metal screws or per listed

vent manufacturer’s instructions.

VENTING

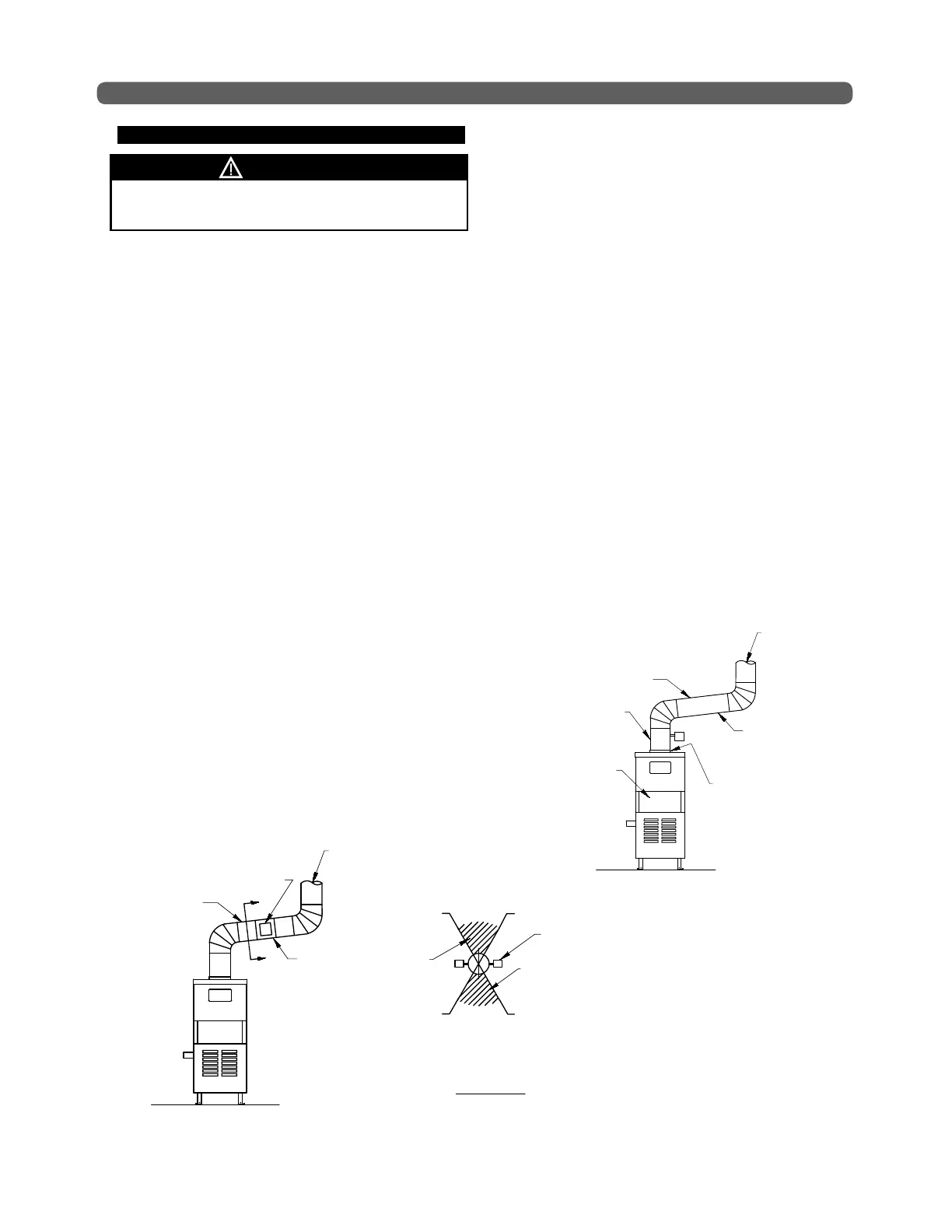

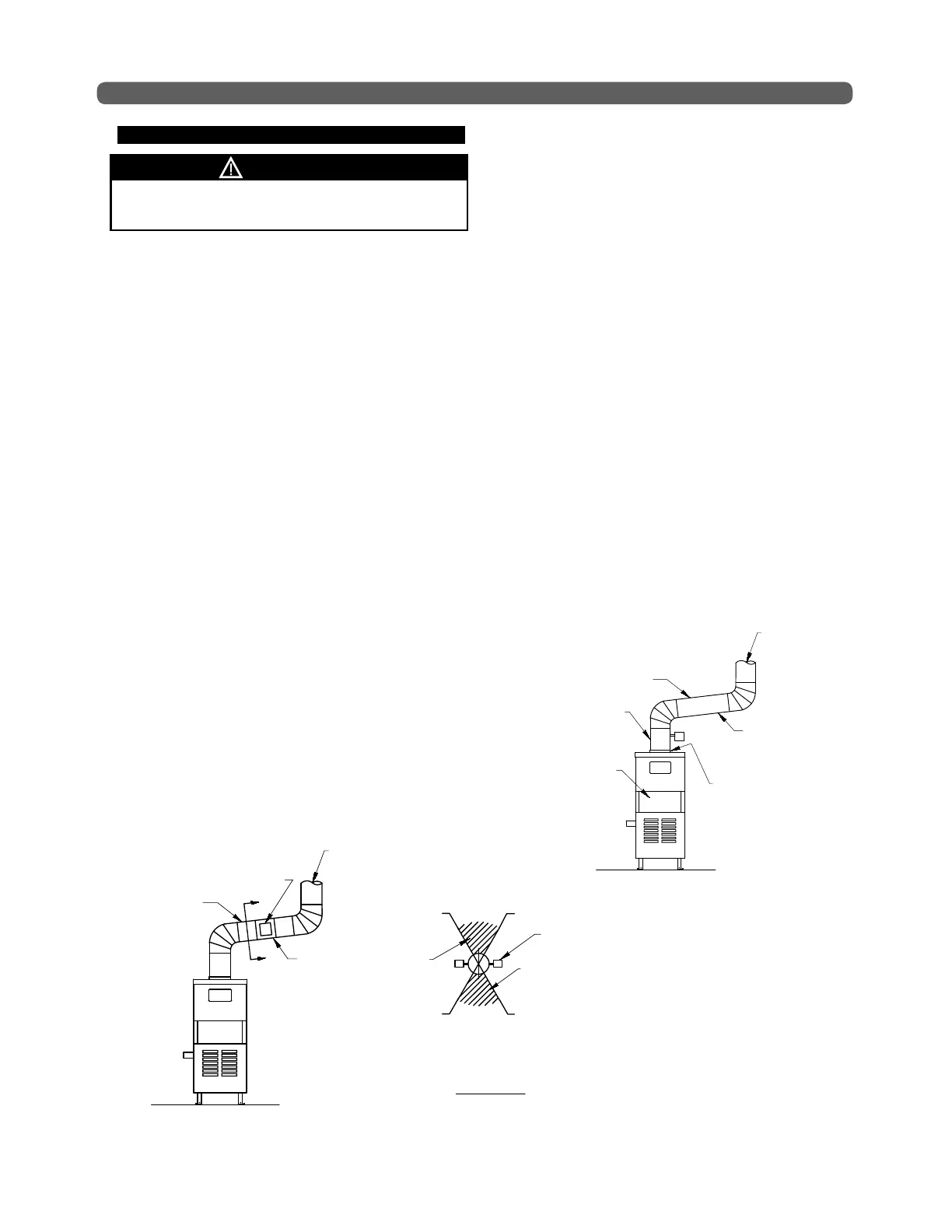

Figure 4.3: Venting with Vent Damper in Horizontal Position

1 O'CLOCK

POSITION

5 O'CLOCK

POSITION

7 O'CLOCK

POSITION

11 O'CLOCK

POSITION

HEAT

ZONE

CONDENSATION

ZONE

A

A

DO NOT MOUNT DAMPER

OPERATOR IN SHADED REGION

DAMPER

OPERATOR

SLOPE UP

A MINIMUM

OF 1/4"

PER FOOT

(21mm

PER METER)

VENT

DAMPER

SECTION A-A

VENT TO

CHIMNEY

SUPPORT AS

REQUIRED

Failure to follow all instructions can result in flue gas

spillage and carbon monoxide emissions.

WARNING

DRAFT

HOOD

RELIEF

OPENING

Loading...

Loading...