21

A. COMPLETING THE INSTALLATION

1. Confirm that all water, gas and electricity are

turned off.

2. Inspect the boiler combustion chamber for foreign

objects and remove if present.

3. Check physical condition of burners and pilot.

Make certain that there are no unusual bends

or perforations in the burners or pilot. Replace

components if necessary.

4. Verify that water piping, venting, gas piping and

electrical wiring and components are installed

properly. Refer back to previous sections of these

instructions as well as equipment manufacturer’s

instructions as necessary.

5. Set the air pressure on the expansion tank to the

system water pressure before filling system. The

pressure reducing valve on the fill line will typically

allow the system to be filled and pressurized to

12 psi (83 kPa). Consult the valve and expansion

tank manufacturer for more specific information.

6. Fill the boiler and system with water making certain

to vent air from all high points in the system. Water

should bleed from each air vent when it is opened.

7. See Section 1 - Preinstallation for boiler water

treatment requirements.

8. Check joints and fittings throughout the system for

leaks. If leaks are found, drain the system and repair

as required.

9. Connect a manometer to the gas valve on the valve

outlet (gas manifold). Use the 1/8 NPT tapping

provided.

10. Confirm that the gas supply pressure to the boiler is

above the minimum and below the maximum values

for the gas being used. See the end of Section 5 for

these values. If a supply pressure check is required,

isolate the boiler and gas valve before performing

the pressure check. If the supply pressure is too high

or too low, contact the gas supplier.

11. Turn on electricity and gas to boiler.

12. Light the boiler by following the Lighting/Operating

Instructions label mounted to the jacket panel.

Operating Instructions are also shown in Figures 7.5

thru 7.8. The initial ignition may require several tries

as the piping is purged of air.

13. Use the sequence description in Figure 6.6 in

Section 6 (Electrical) to follow light-off and shutdown

sequences and to assist in diagnosing problems. If

the boiler does not function properly, consult Section

8, Troubleshooting.

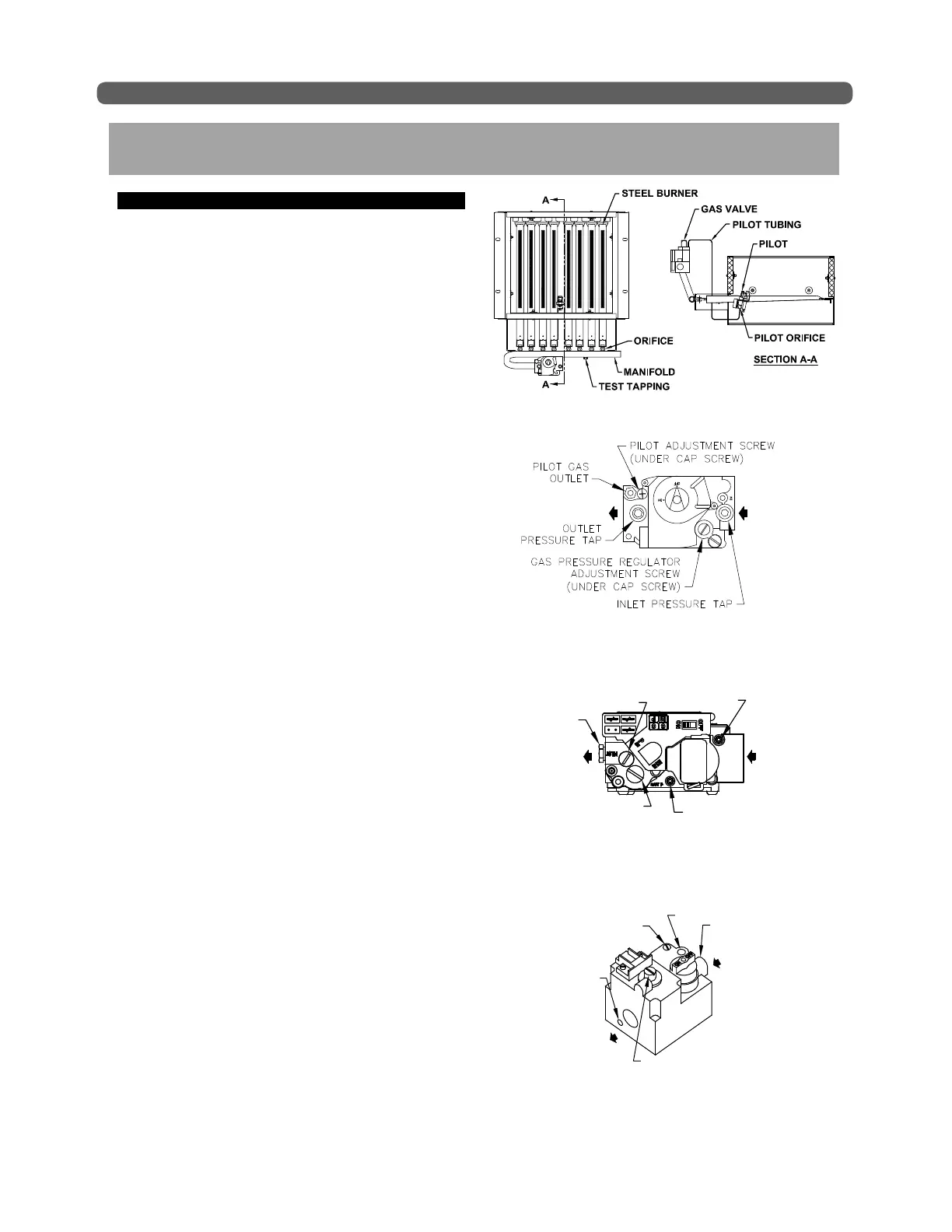

14. The gas manifold and control assembly are made of

gas-tight, completely factory assembled and installed

components of the base assembly. See Figure 7.1.

START-UP PROCEDURES

7. START-UP PROCEDURES

Figure 7.1: Gas Valve, Manifold and Burner

Assembly

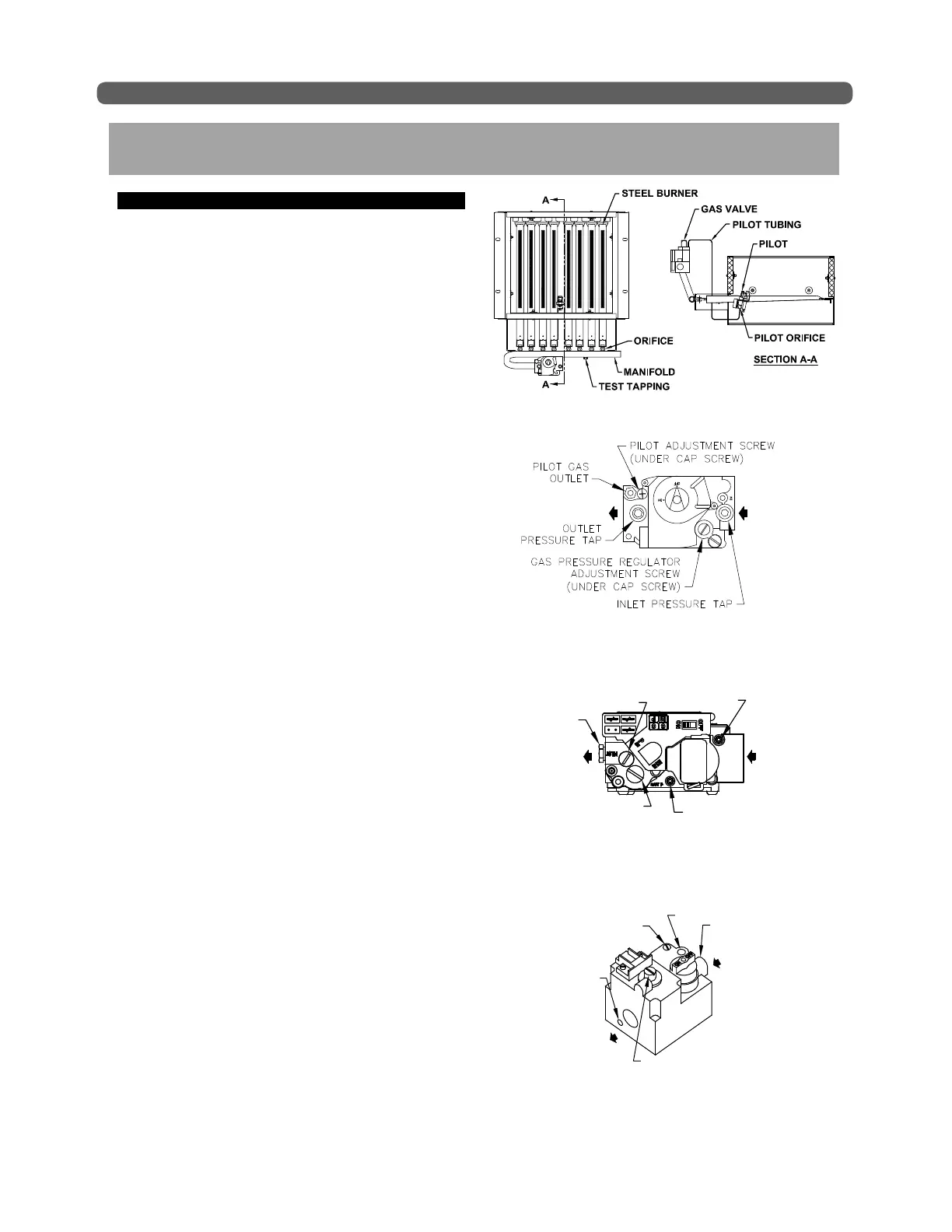

Figure 7.2: Valve Tapping and Adjustment Screw

Locations, Residio Gas Valve

OUTLET INLET

Figure 7.4: Valve Tapping and Adjustment Screw

Locations, Robertshaw Gas Valve

OUTLET

GAS PRESSURE REGULATOR

ADJUSTMENT SCREW

(UNDER CAP SCREW)

INLET

PILOT GAS OUTLET

PILOT ADJUSTMENT

SCREW (UNDER

CAP SCREW)

OUTLET

PRESSURE

TAP

INLET

PRESSURE

TAP

Figure 7.3: Valve Tapping and Adjustment Screw

Locations, White Rodger Gas Valve

OUTLET

INLET

PRESSURE

TAP

GAS PRESSURE

REGULATOR

ADJUSTMENT SCREW

(UNDER CAP SCREW)

INLET

OUTLET

PRESSURE

TAP

PILOT GAS

OUTLET

PILOT

ADJUSTMENT SCREW

(UNDER CAP SCREW)

Loading...

Loading...