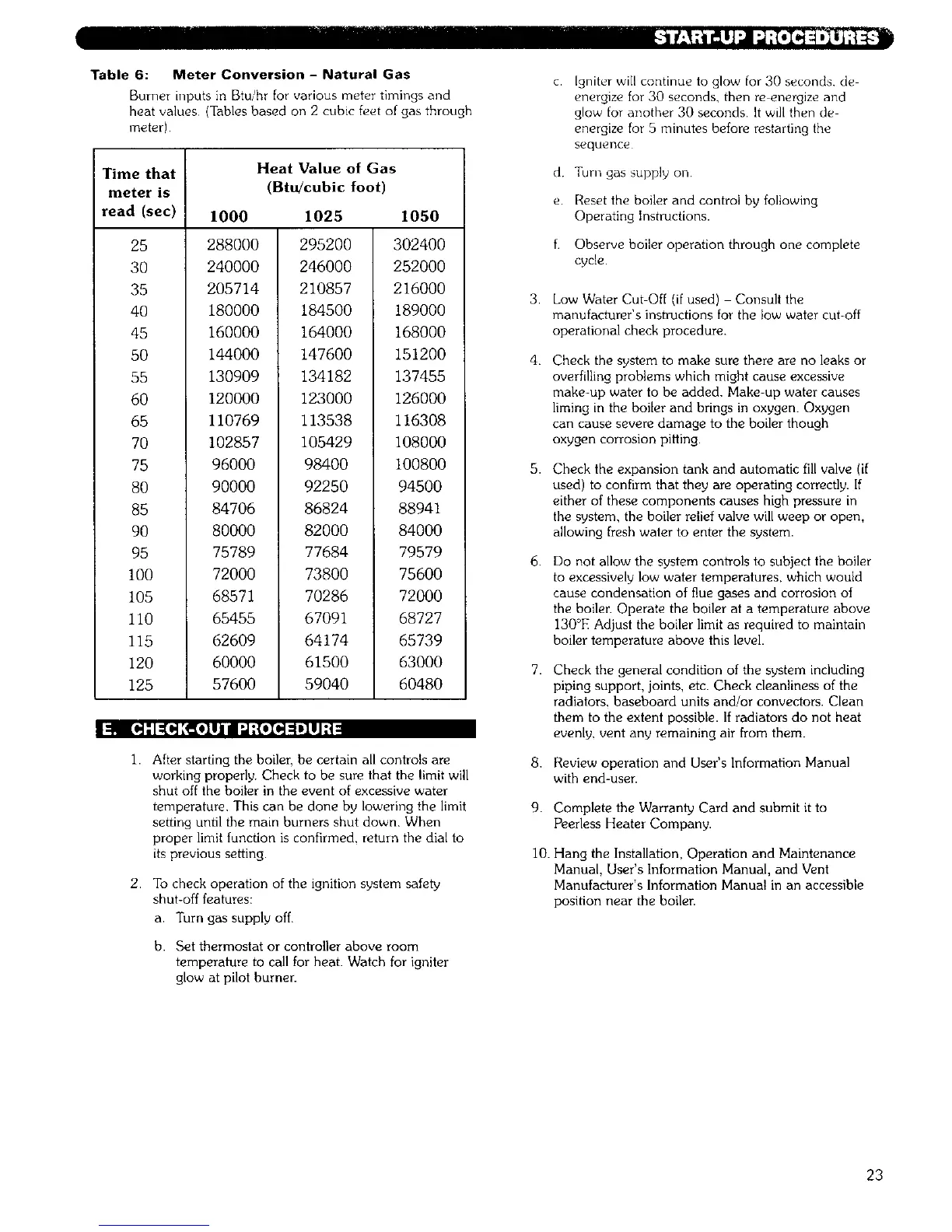

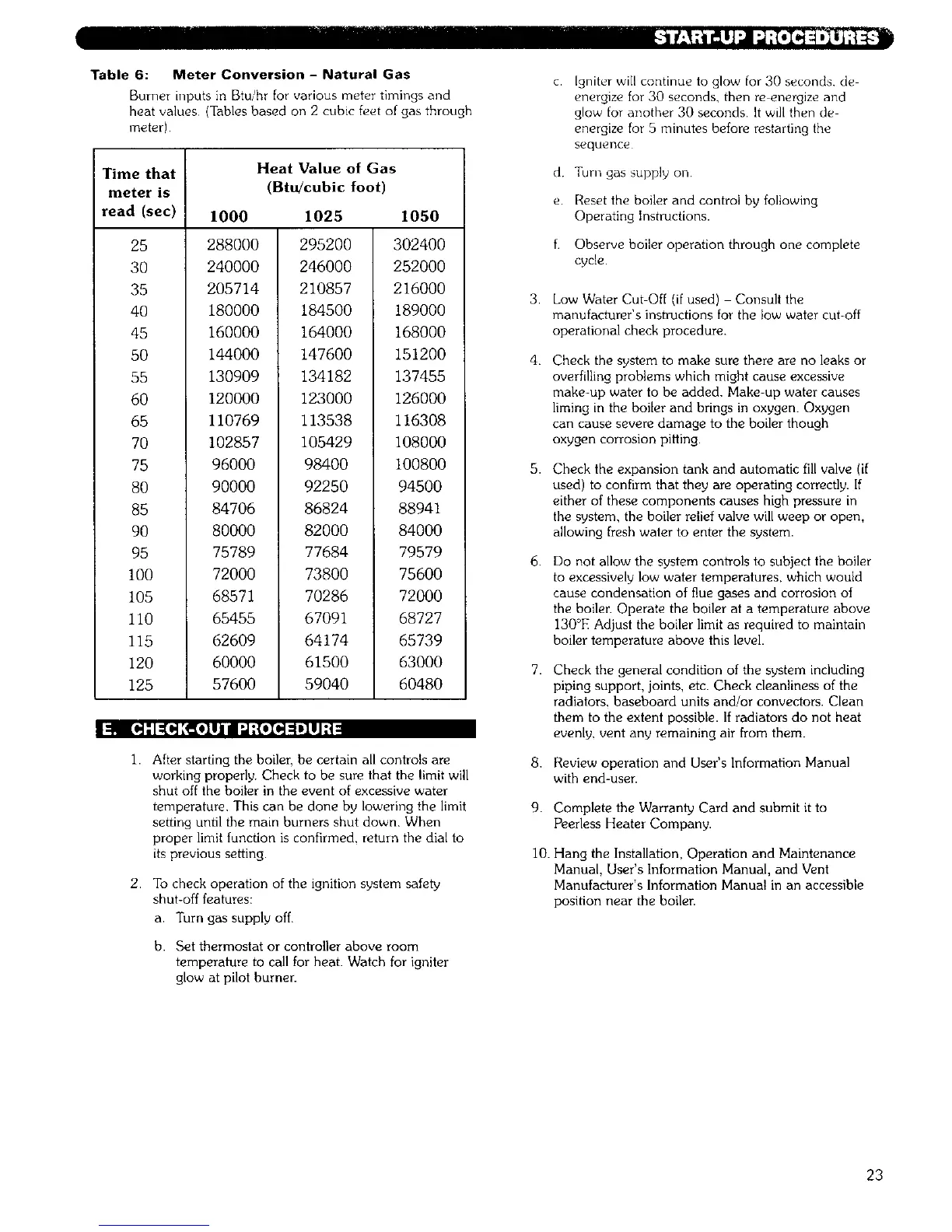

Table 6: Meter Conversion - Natural Gas

Burner inputs in Btu/hr for various meter timings and

heat values (Tables based on 2 cubic feet of gas through

meter)

Time that Heat Value of Gas

meter is (Btu/cubic

read (sec)

25

30

35

40

45

50

55

60

65

70

75

8O

85

90

95

i00

I05

110

115

120

125

foot)

1000 1025

288000 295200

240000 246000

205714 210857

180000 184500

160000 164000

144000 147600

130909 134182

120000 123000

110769 113538

102857 105429

96000 98400

90000 92250

84706 86824

80000 82000

75789 77684

72000 73800

68571 70286

65455 67091

62609 64174

60000 61500

57600 59040

1050

302400

252000

216000

189000

168000

151200

137455

126000

116308

108000

100800

94500

88941

84000

79579

75600

72000

68727

65739

63000

60480

I_ll [_l:l_[_l[_01111111".l;{0I_l_lDlll;t

1. After starting the boiler, be certain all controls are

working properly. Check to be sure that the limit will

shut off the boiler in the event of excessive water

temperature, This can be done by lowering the limit

setting until the main burners shut down. When

proper limit function is confirmed, return the dial to

its previous setting.

2. To check operation of the ignition system safety

shut-off features:

a, Turn gas supply off.

b. Set thermostat or controller above room

temperature to call for heat. Watch for igniter

glow at pilot burner.

c Igniter will continue to glow for 30 seconds, de

energize for 30 seconds, then re energize and

glow for another 30 seconds. It will then de

energize for 5 minutes before restarting the

sequence

d Turn gas supply on

e. Reset the boiler and control by following

Operating Instructions.

f Observe boiler operation through one complete

cycle.

3.

4.

5.

6.

7.

8.

Low Water Cut Off (if used) Consult the

manufacturer's instructions for the low water cut-off

operational check procedure.

Check the system to make sure there are no leaks or

overfilling problems which might cause excessive

make-up water to be added. Make-up water causes

liming in the boiler and brings in oxygen. Oxygen

can cause severe damage to the boiler though

oxygen corrosion pitting.

Check the expansion tank and automatic fill valve (if

used) to confirm that they are operating correctly. If

either of these components causes high pressure in

the system, the boiler relief valve will weep or open,

allowing fresh water to enter the system.

Do not allow the system controls to subject the boiler

to excessively low water temperatures, which would

cause condensation of flue gases and corrosion of

the boiler. Operate the boiler at a temperature above

130°F. Adjust the boiler limit as required to maintain

boiler temperature above this level.

Check the general condition of the system including

piping support, joints, etc. Check cleanliness of the

radiators, baseboard units and/or convectors. Clean

them to the extent possible. If radiators do not heat

evenly, vent any remaining air from them.

Review operation and User's Information Manual

with end-user.

9.

10.

Complete the Warranty Card and submit it to

Peerless Heater Company.

Hang the Installation, Operation and Maintenance

Manual, User's Information Manual, and Vent

Manufacturer's Information Manual in an accessible

position near the boiler.

23

Loading...

Loading...