3. WATER PIPING AND CONTROLS

r,_! I :{e] II! =i:!_'tl J;j "Jk'm,__ _ I w]l ; I =ilI[I J;1h_

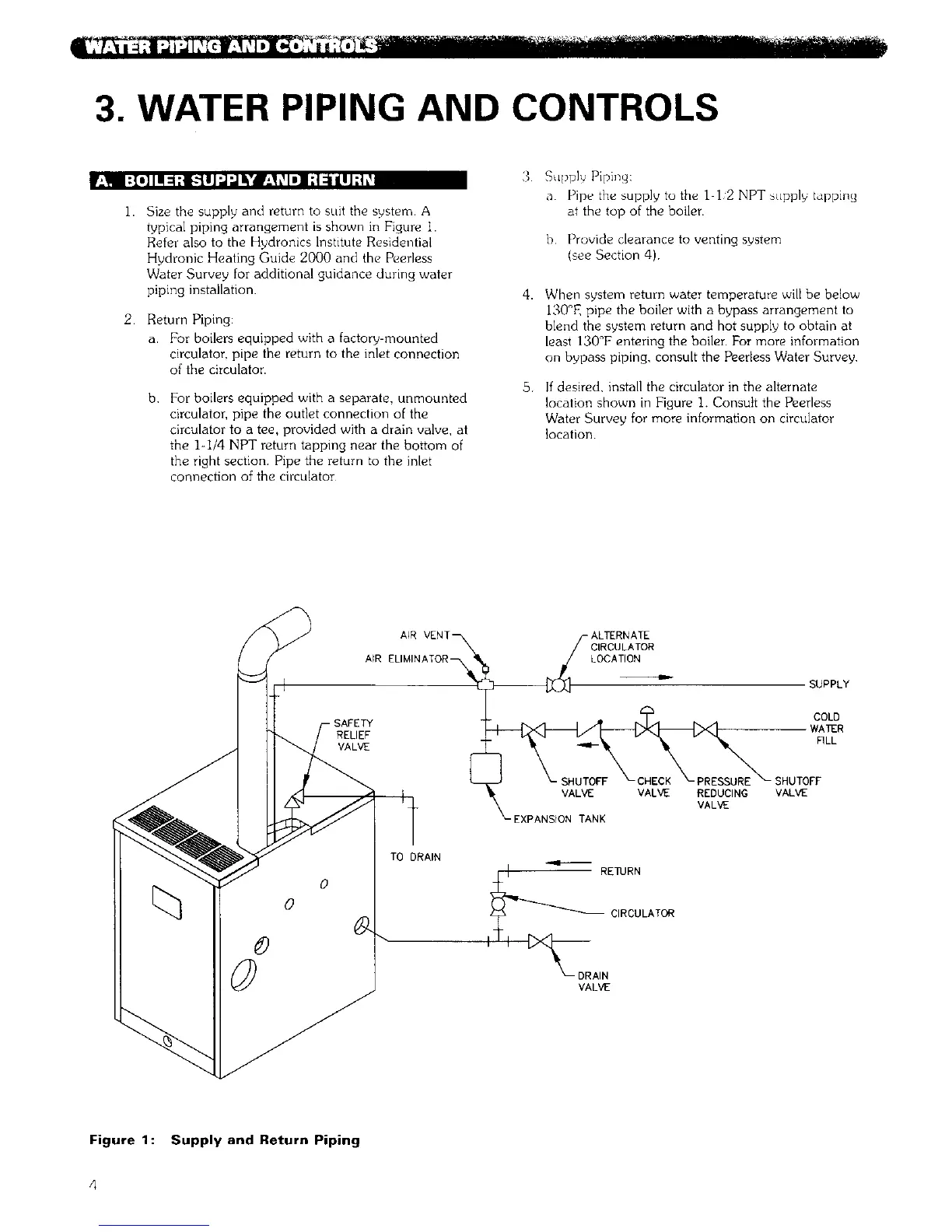

]. Size the supply and return to suit the system. A

typical piping arrangement is shown in Figure i.

Refer also to the Hydronics Institute Residential

Hydronic Heating Guide 2000 and the Peerless

Water Survey for additional guidance during water

piping installation.

2 Return Piping:

a. For boilers equipped with a factory-mounted

circulator, pipe the return to the inlet connection

of the circulator.

b For boilers equipped with a separate, unmounted

circulator, pipe the outlet connection of the

circulator to a tee, provided with a drain valve, at

the 1-1/4 NPT return tapping near the bottom of

the right section Pipe the return to the inlet

connection of the circulator

3

4.

5.

Supply Piping:

a Pipe the supply to the I I 2 NPT supply tapping

at the top of the boiler.

b Provide clearance to venting system

(see Section 4)

When system return water temperature will be below

130°F, pipe the boiler with a bypass arrangement to

blend the system return and hot supply to obtain at

least 130°F entering the boiler. For more information

on bypass piping, consult the Peerless Water Survey

If desired, install the circulator in the alternate

location shown in Figure I. Consult the Peerless

Water Survey for more information on circulator

location

AIR VENT_

AIR ELIMINATOR _

-- SAFETY

RELIEF

VALVE

)_-ALTERNATE

CIRCULATOR

LOCATION

SUPPLY

COLD

WA1ER

NLL

SHUTOFF

VALVE VALVE" REDUCING VALVE

VALVE

_-EXPANStON TANK

0

o

©

TO DRAIN

RE_JRN

CIRCULATOR

DRAIN

VALVE

Figure 1: Supply and Return Piping

Loading...

Loading...