17

4. Y-Type Strainer or Filter Ball

®

Valve: PB Heat recommends

the use of a strainer device in the system to prevent dirt or

sediment from clogging the heat exchanger. A 20 mesh

stainless steel screen is adequate to protect the heat

exchanger. The strainer should be cleaned often in the first

several months of operation. The Filter Ball

®

Valve from

Jomar International incorporates a strainer into a ball

valve which allows the technician to isolate the water

circuit while cleaning the strainer.

5. Flow Control Valve: Flow control valves such as the

TACO Flo-Chek or Bell & Gossett Flo-Control™ are

used to prevent gravity circulation by incorporating a

check valve with a weighted disc.

6. Pressure Reducing Valve: A pressure reducing valve,

such as the Bell & Gossett B-38 or a TACO #329, is

used in a hydronic system to automatically feed water

to the system whenever pressure in the system drops

below the pressure setting of the valve. These valves

should not be used on glycol systems unless close

supervision of the glycol solution is practiced.

7. Back Flow Preventer: A back flow preventer (check

valve) is required by some jurisdictions to prevent water

in the hydronic system from backing up into the city

water supply. This is especially important on systems in

which glycol solution is used as the heating medium.

8. Pressure Relief Valve: The boiler pressure relief valve

is shipped separately for field installation. The valve is

to be installed as shown in Figures 4.2 or 4.3. Pipe the

discharge of the relief valve to within 12" of the floor

and close to a floor drain. Provide piping that is the

same size or larger than the relief valve outlet.

WATER PIPING AND CONTROLS

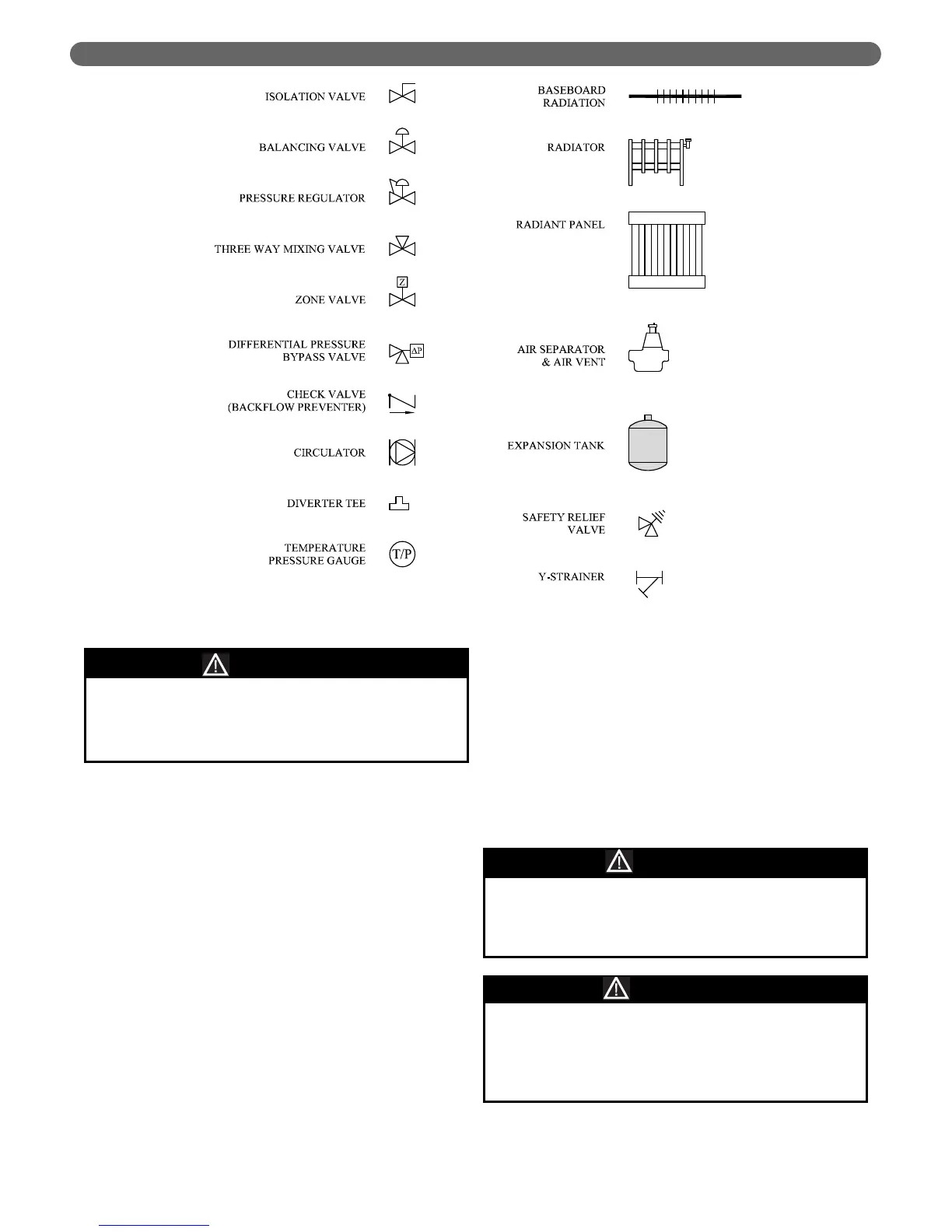

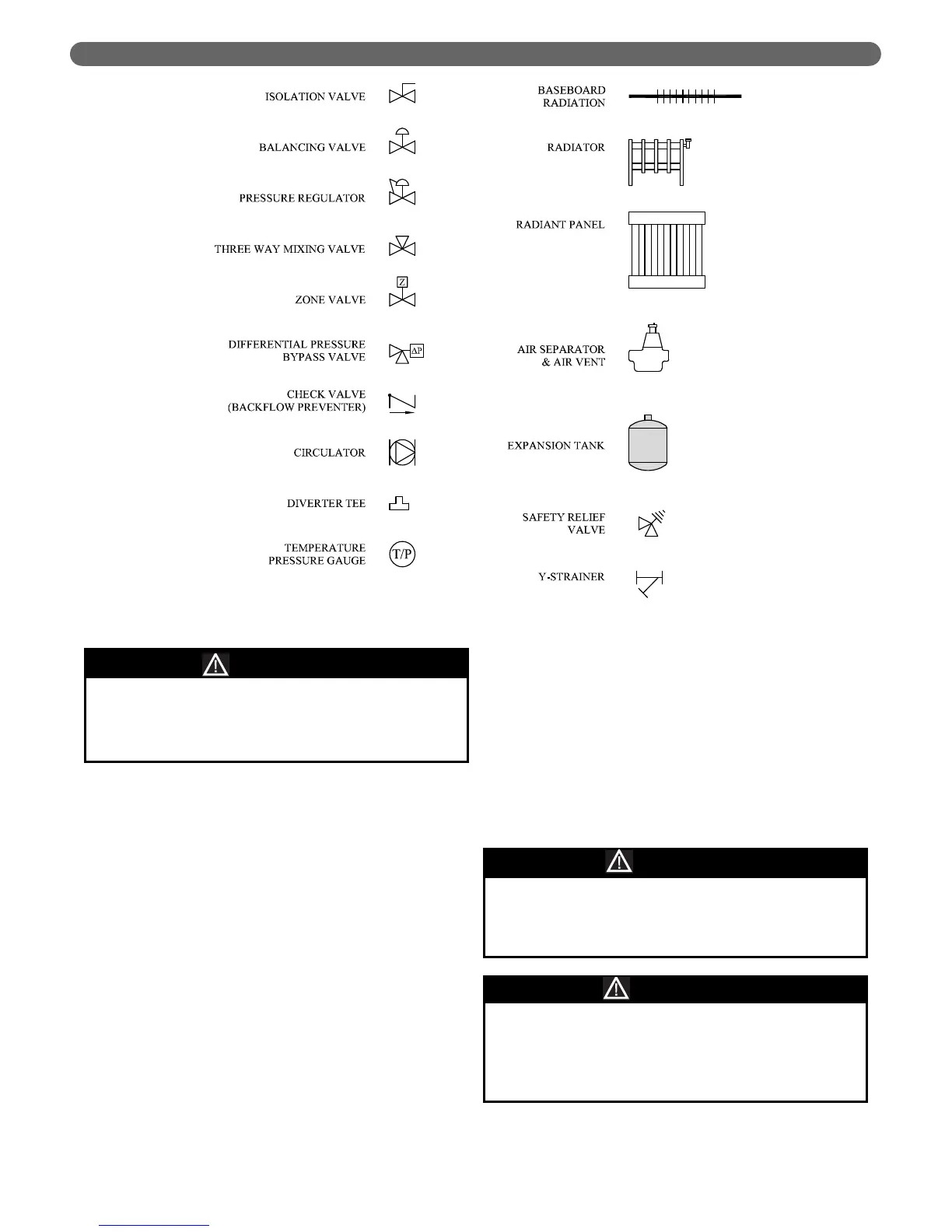

Figure 4.1: Piping Symbol Key

Use only inhibited propylene glycol solutions which

are specifically formulated for hydronic systems.

Ethylene glycol is toxic and may cause an

environmental hazard if a leak or spill occurs.

WARNING

Do not operate this appliance without installing the

pressure relief valve supplied with the boiler or one

with sufficient relieving capacity in accordance with

the ASME Rating Plate on the boiler heat exchanger.

WARNING

Pipe the discharge of the relief valve as close as

possible to the floor and away from high traffic areas.

Pipe the discharge to a floor drain. Failure to do so

may result in personal injury and/or property

damage.

CAUTION

Loading...

Loading...