24

1. Do not install any piping directly in front of the boiler

or along either side. Always provide access to the

front cover and side panel openings.

2. Install a sediment trap as shown in Figure 5.1. Be sure

to allow clearance from the floor or other horizontal

surface for removal of the pipe cap.

* Natural gas input rates are based on 1,000 Btu/ft

3

, LP input

rates are based on 2,500 Btu/ft

3

.

3. Install a ground joint union between the sediment trap

and the boiler to allow service to the appliance.

4. Install a service valve as shown in Figure 5.1 to allow

the gas supply to be interrupted for service.

5. Maintain a minimum distance of 10 pipe diameters

between the gas pressure regulator and the boiler.

6. Check all gas piping for leaks prior to placing the

boiler in operation. Use an approved gas detector,

non-corrosive lead detection fluid, or other leak

detection method. If leaks are found, turn off gas flow

and repair as necessary.

7. Figure 5.1 shows the gas shutoff valve for the Series

PBC™ boiler. This valve is to be used in addition to

the gas service valve shown upstream of the sediment

trap.

D. GAS SUPPLY PIPING - OPERATION

1. The gas line must be properly purged of air to allow

the boiler to operate properly. Failure to do so may

result in burner ignition problems.

2. Table 5.3 shows the maximum and minimum fuel gas

supply pressure to be measured at the gas valve inlet

pressure tap. See figure 5.2.

a. Gas pressure below 3.5 inches of water column for

Natural gas and 8 inches of water column for LP

gas may result in ignition failures and hard

ignitions.

b. Gas pressure above 13.5 inches of water may

result in damage to the automatic gas valve.

3. To check the gas supply pressure to the gas valve:

a. Turn off the power at the service switch.

b. Close the gas shutoff valve.

c. Using a flat screwdriver, turn the screw inside the

inlet tap fitting (see Figure 5.2) one turn counter

clockwise.

d. Attach the tube from the manometer to the

pressure tap fitting.

e. Open the gas valve and start the boiler.

f. Read and record the gas pressure while the boiler

is firing at max input as well as with any other

appliances to the same gas line at their maximum

inputs.

g. Turn off the boiler and close the gas shutoff valve.

h. Remove the manometer tube from the pressure

tap fitting.

i. Turn the internal screw clockwise to close the

valve.

j. Turn on the gas shutoff valve and boiler service

switch.

k. Fire the boiler and check for fuel gas odor around

the gas valve. If an odor is evident check to make

sure that the pressure tap fitting is closed.

4. All gas piping must be leak tested prior to placing the

boiler in operation.

a. If the leak test pressure requirement is higher than

13.5 inches of water column, the boiler must be

isolated from the gas supply piping system.

b. If the gas valve is exposed to pressure exceeding

13.5 inches of water column, the gas valve must

be replaced.

5. Install the boiler such that the gas ignition system

components are protected from water (dripping,

spraying, rain, etc.) during operation and service

(circulator replacement, condensate collector and

neutralizer cleanout, control replacement etc.)

E. MAIN GAS VALVE - OPERATION

1. Figure 5.2 is an illustration of the gas valve/venturi

assembly for the Series PBC™ boiler.

a. Adjustments should not be made to the gas valve

without instrumentation to measure carbon

dioxide (CO

2

) and carbon monoxide (CO)

emissions in the vent pipe.

b. Turning the throttle screw clockwise will decrease

the gas flow (decreasing CO

2

) and turning it

counterclockwise will increase the gas flow rate

(increasing CO

2

). Markings adjacent to the throttle

screw show + and – indicating this operation.

c. The recommended CO

2

settings are given in Table

5.4. In no case should the boiler be allowed to

operate with CO emissions above 200 ppm.

FUEL PIPING

When checking for leaks, do not use matches,

candles, open flames or other methods that provide

an ignition source. This may ignite a gas leak

resulting in a fire or explosion.

WARNING

Do not subject the gas valve to more that 1/2 psi

(13.5" W.C.) of pressure. Doing so may damage the

gas valve.

CAUTION

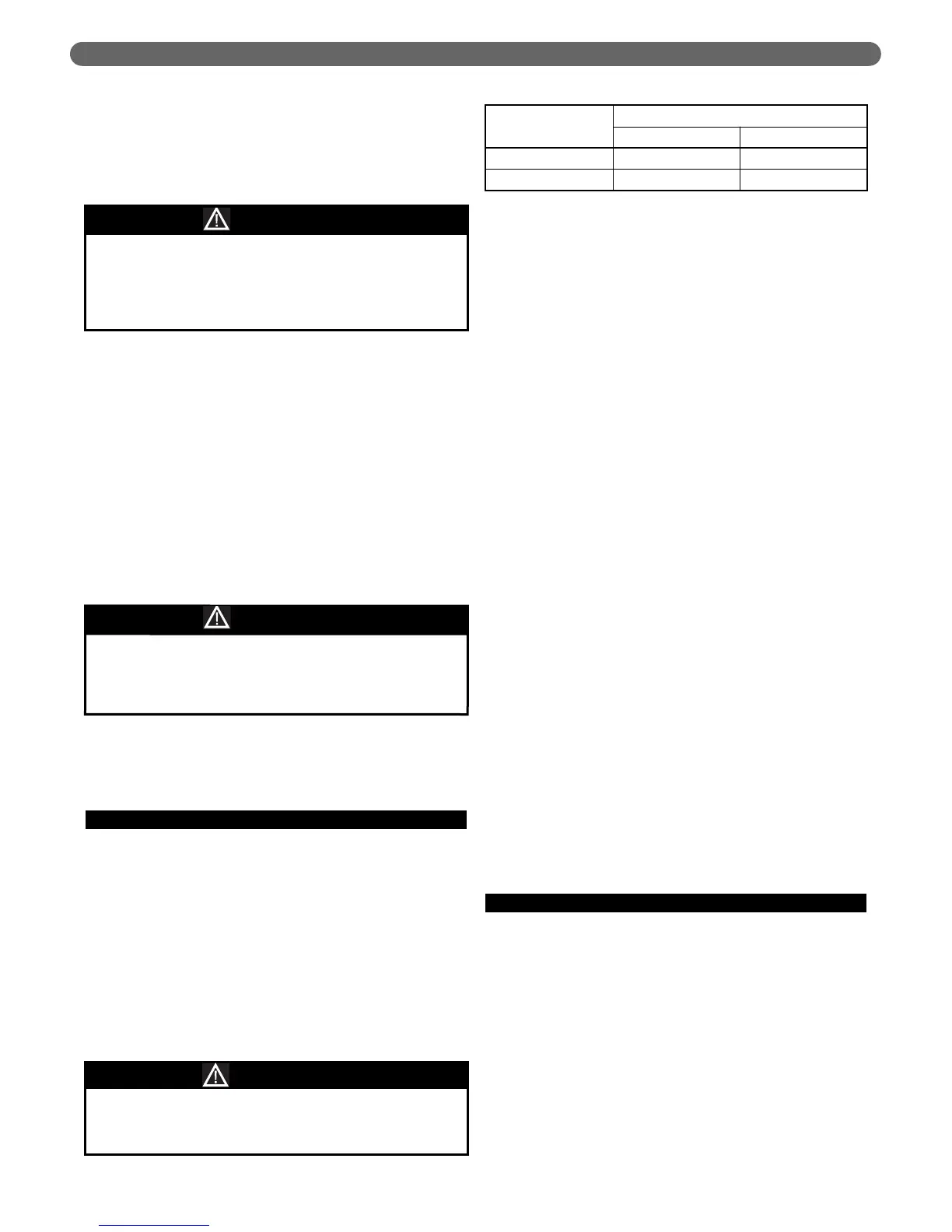

Fuel Type

Pressure Inches W.C. (Pa)

Minimum Maximum

Natural Gas 3.5 13.5

LP Gas 8 13.5

Table 5.2: Maximum and Minimum Fuel Pressure

Use a pipe joint sealing compound that is resistant to

liquefied petroleum gas. A non-resistant compound

may lose sealing ability in the presence of this gas,

resulting in a gas leak. Gas leaks may potentially

cause an explosion or fire.

WARNING

Loading...

Loading...