45

8. Two second flame proving period holds valve open

while control checks for flame signal

9. Boiler holds at ignition speed for 10 seconds before

modulation begin.

10. Demand is met and removed.

11. Gas valve closes, Fan returns to ignition speed.

12. 10 second post purge period.

13. Pump remain energized for pump post purge period.

14. Full unit standby

TROUBLESHOOTING

If overheating occurs or the gas supply fails to shut

off, do not turn off electrical power to the circulating

pump. This may aggravate the problem and increase

the likelihood of boiler damage. Instead, shut off the

gas supply to the boiler at the gas service valve.

CAUTION

DANGER

When servicing or replacing components that are in

direct contact with the boiler water, be certain that:

• There is no pressure in the boiler. (Pull the release

on the relief valve. Do not depend on the pressure

gauge reading).

• The boiler water is not hot.

• The electrical power is off.

When servicing or replacing any components of this

boiler be certain that:

• The gas is off.

• All electrical power is disconnected.

WARNING

Do not use this appliance if any part has been under

water. Improper or dangerous operation may result.

Contact a qualified service technician immediately to

inspect the boiler and to repair or replace any part of

the boiler which has been under water.

WARNING

Label all wires prior to disconnection when servicing

controls. Wiring errors may cause improper and

dangerous operation. Verify proper operation after

servicing.

CAUTION

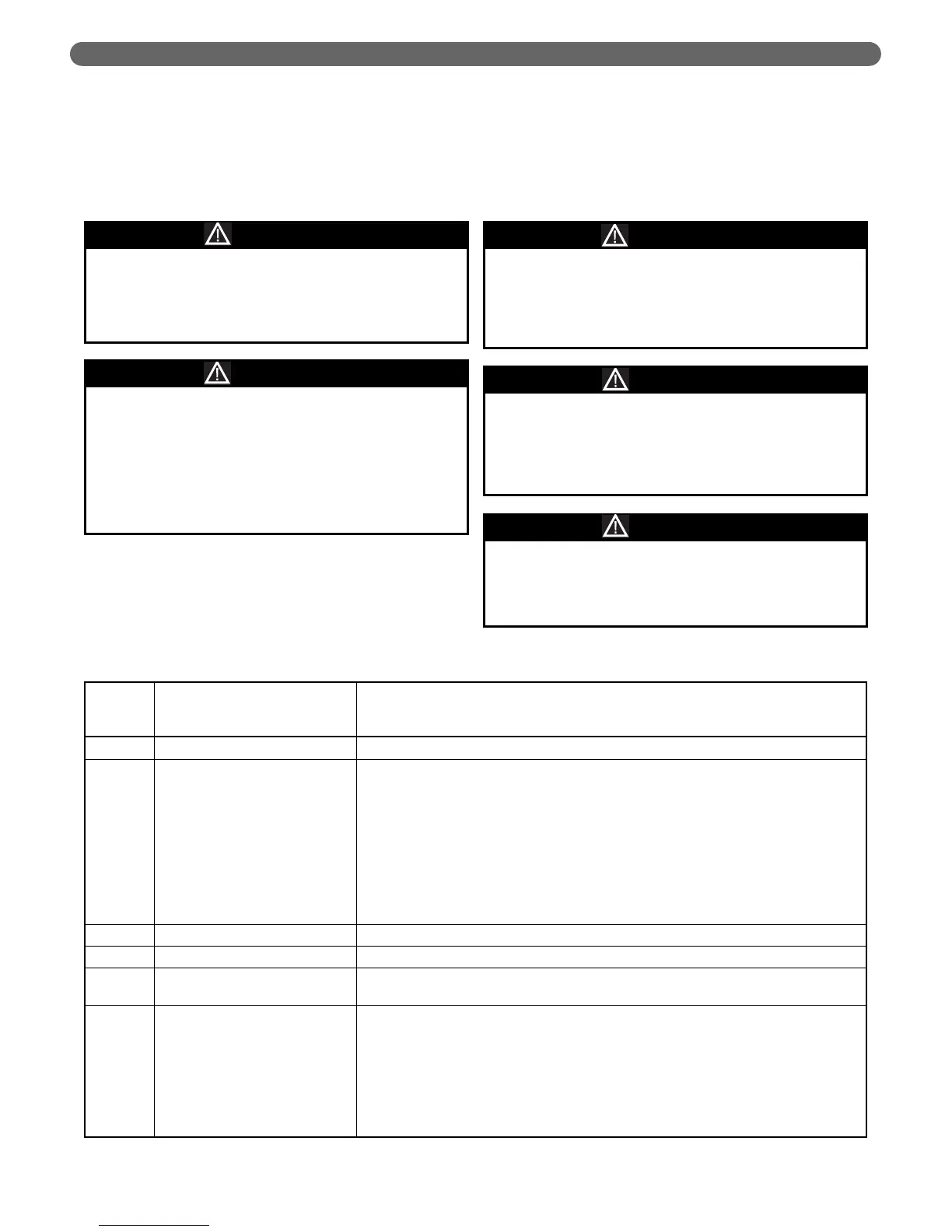

Table 10.1: Lockout Codes

Error

Number

Error Display Corrective Action

0 E2PROM_READ_ERROR

Internal Software error. Replace control.

1 IGNIT_ERROR

Three unsuccessful ignition attempts in a row.

–

Check for spark by ear. Also check for 120V across the blue and brown control output wire

to the spark module. If not spark is present but voltage is. Replace module. If no voltage is

present check parameter 2126. Should be set to 9. If setting is correct, replace control.

–

Remove flame sensor and check for white build-up. Clean sensor, re-install and attempt

ignition. If ignition still fails perform other actions listed here. Replace sensor. If sensor

appears cracked or bent, replace sensor.

–

Confirm fuel pressure at the valve inlet when the valve is open. Low gas pressure can

cause ignition failures. High gas pressure can cause the valve to not operate and or

damage the valve.

2 GV_RELAY_ERROR

Failure detected in the Gas Valve Relay. Replace Control

3 SAFETY_RELAY_ERROR

Failure detected in the safety relay. Replace Control.

4 BLOCKING_TOO_LONG

Blocking error present for more than 20 hours.

–

Go to parameter 1052 for last blocking error code. Correct cause.

5 FAN_ERROR_NOT_RUNNING

Fan is not running for more than 60 secs.

–

Check fan condition by disconnecting the 5 pin control plug on the blower. Fan should

ramp to full power when the unit is turned on.

–

If fan does not power on, check for 120 volts across the brown and blue wires in the three

pin connector. If voltage is present, replace blower.

–

If fan powers on check for continuity through blower control harness, 5 pin connector to

J4 connector on control board. If continuity is found replace control. If no continuity is

found, replace harness.

Loading...

Loading...